- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- angle of rotation sensors

Results for

Angle of rotation sensors - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental rotation sensors are used wherever displacement, positions or speeds have to be measured accurately. They are therefore important interfaces between the mechanical and electronic parts of a machine. Mechanically robust, electrically reliable and resistant to extreme ambient conditions; these are the outstanding properties offered by this sensor. Typical applications include —Machine tools —Wood and plastic machining —Textile machines —Lifts —Door systems —Paper machines —Drive equipment —Assembly and handling equipment —Packaging machines —Scales —Test machines —Conveying equipment —Doors and gates Specific characteristics —Degree of protection IP65, all-around —Robust —High resistance to interference —Rotary speed sensor: 60 pulses/turn (standard) —Angular displacement sensor: up to 3600 pulses/turn —Detection of rotation direction (channels A and B) —Reference pulse (channel N) —Special versions on request

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

As an angle sensor that is both accurate and economical, this rotary potentiometer is suitable for all types of analog angle measurement up to 350°. Typical fields of application include: —Position feedback in servo-systems —Pendulum weighing machines —Cam and butterfly flap positions —Jockey roller controllers —Measuring the tension of threads and tape —Trigonometric measurements at joints The heart of the potentiometric angular displacement sensors is an extremely precise, low-wear resistor track made of plastic. Due to its high resistance to abrasion, the sensors are particularly suitable for measurements for the purpose of quality assurance in ongoing production, where a long service life and large numbers of rotations are required. The potentiometric angular displacement sensor uses a multi-finger slider system with precious metal contacts. This ensures good contact even when moving at high speed and in the presence of vibrations.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The compact torque sensor model 8655 with standard square is contactless constructed. The torque is recorded by the torsion of the shaft using the strain gage principle. Thanks to the inductive and optical transmission of the signals, the sensor is maintenance-free, the signals are digitized directly on the shaft and made available by the evaluation electronics as a voltage signal or via USB. The direction of rotation can be seen from the potential of the output voltage, clockwise rotation corresponds to positive output voltage, counterclockwise rotation the voltage level is negative. The standard square enables simple integration into existing systems or devices, additional components such as couplings are not require. To record the speed and angle of rotation, the sensor can optionally be equipped with an incremental disc with 400 increments. This speed / angle signal is available as a TTL output signal.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications. GMN high-speed spindles of the HC, HCS, UHS, HCT series are an essential component of highly-effective machining of various materials. Whether aluminum, steel or titanium, these spindles are optimally designed for all machining tasks which require performance, torque and speed. Using an oil-air or grease permanent lubrication, the spindle bearings operate in a secure fashion.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

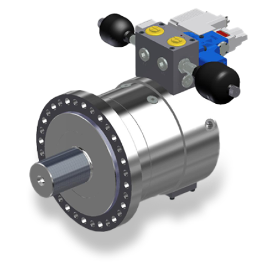

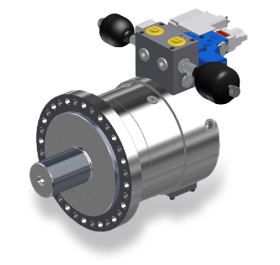

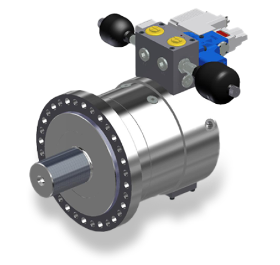

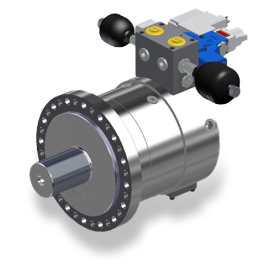

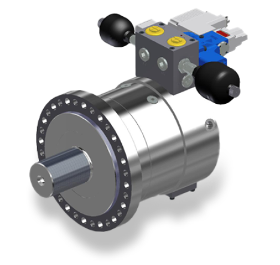

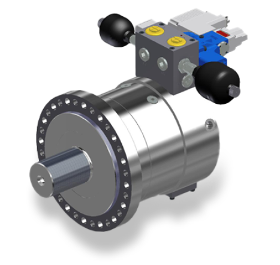

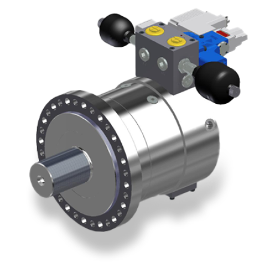

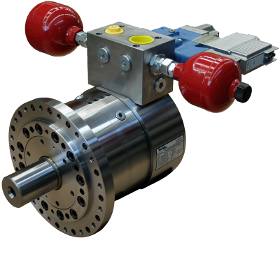

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Thanks to a wide range of accessories, Hense operators can be individually configured for a wide variety of applications and optimally matched to the function of the overall system. To ensure perfect and safe operation, we are on hand to help you select and optimally coordinate all components.Servo valves, proportional valves and switching valves with different nominal sizes Pulsation damper for smoothing vibrations and uneven flow rates Subplates for positioning valves and pulsation accumulators close to the motor High-resolution rotation angle sensors that are coupled directly to the swivel motor shaft by means of a torsionally rigid coupling Pressure sensors Torque measuring shafts or reference torque measuring disks Clamping sets, shrink disks or profiled hubs for torque transmission Torsionally rigid couplings for reliable torque transmission with simultaneous shaft displacement Angled flanges for mounting the swivel motors parallel to the axis

Request for a quote

NORIS GROUP GMBH

Germany

Rotary position sensors of type DWA are mechanically connected rotary position encoders. They measure the rotary position in accordance with the ohmic principle. These rotary position sensors are suitable for measuring the rudder or pitch position, for example. Mechanically connected rotary position sensor, ohmic principle. 360° rotation angle without mechanical limitation. Reference positions easy to adjust mechanically. Maintenance-free operation. No reference run necessary. Potential-separated channels. Approvals: ABS, BV, DNV-GL, MED

Request for a quote

MEGATRON ELEKTRONIK GMBH & CO. KG

Germany

The RP19/20 potentiometers in Ø22 mm housing are suitable for applications where an accurate and compact sensor with high electrically effective rotation angle is required. The RP19/20 potentiometer series (RP19 with mechanical end stop) is an all-rounder which is adaptable for a wide range of applications and is often used as a feedback sensor in valve control systems. In addition, the sensor convinces by its good accuracy. The radial gold-plated connection pins are suitable for flat connectors (2.8 mm according to DIN 46247 part 3). Accurate wirewound potentiometer Very high electrically effective angle of rotation 355° ±5° Compact sensor with 12 mm installation depth With or without mechanical end stop (320° / 360°) Optional tandem version / max. 10 in a row possible

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

Features ■ Pressure transmitter with on-site indication for relative pressure measurements ■ Safety pattern gauge S3 per EN 837-1, NS 100 and 160 alternative high quality case with bajonet ring per EN 837-1 S1 ■ Nominal range 0…0.6 bar up to 1000 bar ■ Output signal: 4…20 mA (20…4 mA) 2-wire technology ■ Integrated angle-of-rotation sensor, not subject to wear ■ EAC declaration (upon request) Options ■ Approvals/Certificates - Calibration certificate - Explosion protection for gases and dust - Certificate of measuring equipment for Russian Federation - Material certificate as per EN 10204-3.1 ■ The electrical zero can be corrected by holding a ferromagnetic object to a marked location on the case ■ Additional switch function ■ Diaphragm seals see product group D5 ■ Output signal 0...20 mA and 0...10 V in 3-wire technology (for devices without Ex-protection and without zero point setting)

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

Gas expansion thermometer NS 100/160, various process connections Features High quality case with bajonet ring NS 100/160, degree of protection IP 66 Nominal ranges -40 °C…700 °C, further nominal ranges from -200 °C...700 °C upon request Case and wetted parts of stainless steel Different connections can be supplied Temperature detecting element 6, 8 and ≥ 10 mm diameter Short immersion lengths of the temperature detecting element may be used Accuracy class 1 as per EN 13190 Micro adjusting pointer for indication correction EAC declaration (upon request) Options Explosion protection (ATEX) for mechanical devices Certificate of measuring equipment for Russian Federation Calibration certificate as per EN 10204 Case with liquid filling Electronical angle-of-rotation sensor, Type series PL1100, see data sheet D6-020 Connection to zone 0 with thermowells (upon request)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Angle of rotation sensors - Import exportNumber of results

18 ProductsCountries

Company type