- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminium sheet bending

Results for

Aluminium sheet bending - Import export

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

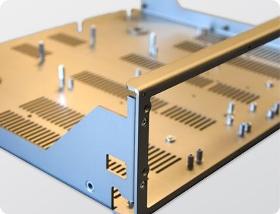

The process is CNC milling and bending. The material is aluminum. The surface treatment is purple anodized.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Laser cutting bending aluminum sheet metal parts

Request for a quote

BASAK LAZER

Turkey

We can shape metal materials with our press brake machine with a capacity of 380 tons. We can shape your aluminum, stainless steel and ST series metal sheets in the desired form.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

We are the Stainless Steel Stamping Parts manufacturer. At FRIMA PARTS, we offer the custom sheet metal fabrication services .The metal manufacturing process contains Stainless Steel Stamping Parts, Deep drawing stamping,CNC punching, CNC bending. The 2000+ projects we have done for our clients from the overworld. Our skilled mold designer will take customer requirement of the parts into consideration during the mold design and manufacturing. Stainless Steel Stamping Parts (Tolerance range +/-0.02mm) We understand that our customers need exceptional products that are consistent with quality, design and build specification. Our company has invested heavily in advanced stamping, bending, deep drawing equipment, enabling us to quickly deliver components in the volume you need. For more information, please contact us at info@frimaparts.com

Request for a quote

BOHEMIA METAL PARTS

Czech Rep.

We'll bend and set the sheet meta according to your drawing, so that the metal products get firmness, which helps you to save money on welding

Request for a quote

ADMET SP. Z O. O.

Poland

We offer sheet metal bending for all kinds of materials. Maximum width: 3000 mm Maximum thickness: 6mm

Request for a quote

MARXAM PROJECT

Poland

CNC bending of sheet metal technology is the most popular method of plastic processing, allowing to obtain details of both simple and complex shapes. The use of modern press brakes allows for the maximum possible repeatability in cnc bending of the produced elements for any number of items. The modern CNC tube bending services and the automatic compensation of the deflection arrow give maximum accuracy and repeatability in 7 axes and allow you to maintain the required angles along the entire length of the bending line. An extensive tool park allows us to adapt to any customer’s technological requirements. We offer sheet metal bending services, such as tube bending, metal curving, metal sheet folding, aluminum sheet bending, bending steel and many more.

Request for a quote

ALLIED FOR TECH

Poland

We offer complete manufacturing solutions based on the customer technical data and requirements.

Request for a quote

FOXLASER

Bulgaria

Sheet metal bending The two key words when it comes to sheet metal bending are accuracy and quality. FoxLaser guarantees both, thanks to the latest generation of digital, hydraulic press brakes from the Japanese company AMADA. The 7-axis control allows for a very fast process in the production of test parts and prototypes of bent sheet metal, as well as perfect repeatability of the bends in long series. FoxLaser owns nine press brakes for bending, three of which of a brand-new generation, with the option of external programming. Combined with AMADA's specialized BendCam software, they speed up and improve the prototyping process immensely. We are proud owners of a large-sized press brake machine, which allows bending of sheet metal parts up to 4000 mm and also one with a capacity of 320 t by 3000 mm. Additionally, we have manual sheet metal bending machines, press brakes and three-shaft rounds (for cylindrical and conical molding).

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Abkant bench is a kind of press machine used in bending or folding metals. Today many computerized Abkant machines are available. It has improved production by making it faster, saving time, and with respect to shapes. Cylindrical, conical, elliptic and oval materials may be produced by Abkant bending process. In selecting Abkant press, length, thickness and type of the material to be folded (stainless steel, aluminum, conventional sheet, ST, etc.) are important. The machines have separate molds and radii specific to them for various folding processes. A calculating metal sheet angle in Abkant folding is a job requiring expertness. Otherwise, folding lengths may not be produced at the required size. We, as Ramazan Aycan Sheet and Steel Processing Center, we provide you with guaranteed services with our expert staff

Request for a quote

U.E. NAMAS-M

Belarus

We can bend different parts from sheet metal. Maximal length - 3000mm (up to 6mm thickness) Maximal thickness - 10mm (up to 900mm length) Bending operations we make on Trumpf bending machine (Germany)

Request for a quote

MBM METALWORK JSC

Bulgaria

One of our metalworking service: press brakes

Request for a quote

TRIBUNAS & FIGUEIREDO, LDA

Portugal

We offer sheet metal bending services up to 3m. We have high-performance press brakes with 7 axes and up to 160 tons of bending force.

Request for a quote

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

MARXAM PROJECT

Poland

The use of appropriate technology and high-precision machines allows us to ensure that plate rolling operations are carried out according to each customer’s request. The machines we use for rolling metal, have a very wide range of metal sheet rolling, which are intended for serial production (industrial sheet rolling), as well as for individual, single projects. The use of modern machines for bending sections allows us to provide service also during aluminum bending or sheet rolling operations of closed profiles and pipes.

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

With our CNC-controlled folding machine HFE M2 5020 from Amada, we bend aluminium, steel or stainless steel in the sheet metal area perfectly into your desired shape. Depending on the material thickness, we process sheet metal up to a width of 2000 mm.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Grade: 1000-8000Series Temper: O-H112 Type: Plate, Aluminum circle Application: Reflective Sign Boards Width: 70mm~1600mm Surface Treatment: Coated Place of Origin: China Model Number: 1050,1060,1100,3003 7075 Alloy grade: 1000-8000series Thickness: 0.5mm-8.00mm Certification: ISO9001 SGS Standard: GB / T3880 ASTM B209 Supply Ability: 5000 Ton/Tons per Month Packaging Details: standard export packing Lead time:15-30days Port of shipment: Xiamen Payment term:T/T,L/C etc.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis G77Ac anodized aluminum sheet produces a material with a natural gray matte tone. The surface is designed for use in both internal and external aluminum architecture, making it desirable for facades, roofing and interior cladding. Similar to our other anodized aluminum sheet products, Novelis G77Ac can be processed further, such as roll forming, stamping, edging and bending.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Designed specifically for ceilings, Novelis offers SKY® pre-painted decorative aluminum sheet. Quick and easy to clean, it’s particularly suitable for hospitals and restaurants. For those modern designs that demand extra brilliance, Superbright® pre-painted rolled aluminum is ideal for false ceilings. A transparent lacquer protects while bringing unparalleled levels of reflectivity – just the accent needed to make modern design shine.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Good formability and conductivity make our products useful for condenser case products produced via drawing processes. Manufacturers of these aluminum case applications rely on Novelis to provide high-quality aluminum coils or sheet in alloys such as 1050 and 3004. Novelis produces pre-painted aluminum for scales, dials and nameplates in laser engraving quality, in the form of a surface-treated coil or sheet. Specialized coatings are applied by rollers. Printing is possible via standard commercial inks and paints with no special materials required.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

In the aerospace industry we specialize in the production of rolled aluminum plate and sheet materials for fuselage and wing structure components according to standard or customized specifications. The aerospace industry is building new aircraft to accommodate a growing number of air passengers and to replace older, less efficient planes with newer, more fuel-efficient models. Aluminum offers a high strength-to-weight ratio, energy efficiency, and high tolerance to extreme temperatures- making it an ideal material for the manufacturing of aircraft. It can also be recycled repeatedly, making it a good choice as manufacturers pursue sustainability initiatives. We have introduced new low-density alloys that represent an innovative step forward for aluminum in aerospace. Weight-savings from these new alloys translate into fuel efficiency and lower operating costs for the airline industry.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis specialty aluminum offers a range of possibilities for interior and decorative designs. The light weight and flexibility make it ideal for use in aluminum ceiling panels. Smooth or perforated, Novelis pre-painted products can be used for aluminum ceiling panels, grid ceilings, long panel cassettes, lamp grid elements, substructure partitions, aluminum decorative panels and support rails. The aluminum also can be combined with other materials to achieve excellent acoustic absorbance. With the modular production of aluminum ceiling tiles, if there’s ever any damage, only that area requires replacement, making maintenance simple and more cost-effective. With the versatility of aluminum, interior spaces can be as visually impressive as the exterior. Novelis pre-painted and anodized aluminum can make rooms better from the top down, providing options to enhance ceilings in a room, as well as the furniture to fill it.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis aluminum sheets arrive with protective film in place on delivery, and they can be processed easily for perfect edges and flawless corners. In addition, we test the surface and substance of all our products to conform to the highest international quality standards. Novelis offers two corrosion-resistant alloys of tension-free aluminum sheeting, including the hard-wearing AIMg3 alloy, to simplify reinforcement and reduce substructure costs. This stability makes it a superior choice for plastic or composite sheeting. It also means it can be recycled completely at the end of the product’s life for the current market value of the metal.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Smartphones, laptops and digital music players rely on the durable, lightweight and attractive qualities of aluminum. Our technically sophisticated material impacts the latest designs, providing both a technical advantage, as well as an attractive visual ambience. Aluminum enclosures dissipate heat, while the material’s resistance to the effects of weathering makes it ideal for use in outdoor applications as varied as housings, rod antennae and satellite dishes.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis offers industrial aluminum coils and sheet in alloys for the main board and back cover of LED TVs and LCD monitors. Leading LED TV manufacturers, including Samsung and LG, call upon Novelis to supply critical parts such as back panel, bottom chassis, bezel and stand structures for some of the largest, most brilliant displays on the market today.

Request for a quote

ESTIMET SP Z O.O.

Poland

We provide sheet metal bending services using three precision Trumpf press brakes (TruBend_3100, TruBend_5085; TruBend_5320) with a maximum pressure of 320 tons and a maximum bending length of 4000 mm. Our well-equipped inventory of bending tools enables us to manufacture even the most complex parts, and dedicated software supporting machine operation allows us to simulate the bending process. All this guarantees the execution of orders with extreme precision and accuracy. In addition, in our machine park we have two CNC bending machines for bending pipes and profiles. We operate on both mandrel and mandrelless benders, while specializing in bending pipes and profiles. In our plant we deal with bending of, among other things: - structural steel - galvanized steel - stainless steel - aluminum

Request for a quoteResults for

Aluminium sheet bending - Import exportNumber of results

66 ProductsCountries

Category

- Aluminium sheets and bands (32)

- Bending - steels and metals (19)

- Milling - steels and metals (7)

- Aluminium alloys (2)

- Bending machine tools (1)

- Cutting - steels and metals (1)

- Finished Metal Products (1)

- Folding - steels and metals (1)

- Folding machine tools (1)

- Industrial sheet metal work (1)

- Swimming pools - equipment and installations for water treatment (1)