- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminium manufacturing

Results for

Aluminium manufacturing - Import export

STANDART ALUMINIUM

Turkey

S-L Foot is designed for connecting S-Lock and S-Armor series. For further info: info@standartaluminyum.com

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis continues to accelerate the development of its innovative aluminum transportation materials to expand global product offerings for more sustainable buses, trucks, trailers, trains and other forms of commercial transport. Aluminum-intensive vehicles are not only up to 40 percent lighter than those made with steel, they are also safer and more durable. Given their unique properties, aluminum transportation materials continue to emerge as the material of choice for the industry. Manufacturers rely on aluminum’s many benefits, including diverse application development for electric vehicles and emerging mobility demands, superior energy absorption for crash management products and safety, and greater design flexibility due to strength, joining and formability properties, enabling better driving dynamics and vehicle agility.

Request for a quote

ALUMINIUMWERK UNNA AG

Germany

Aluminiumwerk Unna AG one of the world’s leading manufacturers of aluminium alloy tube. We produce a variety of specialist aluminium alloy products. Our core focus is the production of aluminium alloy tube and tubular profiles. These can be offered as seamless extruded or porthole extruded products. The extruded products can also be cold drawn making it possible to offer a comprehensive range of final dimensions.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Super lightweight reusable dash aluminum fittings. Manufactured according to aviation standards, suitable for petrol, oil, methanol, water and air. The first choice when it comes to reliable and flexible hose lines.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Light, durable and corrosion-resistant, pre-painted aluminum sheeting products make an ideal base for aluminum license plate manufacturing for cars. Benefits include minimum burr on edges thanks to superior processing, corrosion resistance ensured by a specialized coating on the reverse side and versatile delivery options from coils and sheets to cut blanks and ready-made license plates, which include rounded corners, embossed edges and a painted finish. The alloy and coating are specifically adapted for government requirements and are delivered in accordance with local regulations. Consistency is also ensured with excellent quality controls and compliance with all regulatory bodies, including EN, DIN, ASTM, BS and ECCA. Lastly, aluminum license plate products provide excellent adhesion qualities for reflective film and other applications thanks to a clean, grease-free surface. Choices include top-coating or pretreatment options, or double-coated for non-reflective plates.

Request for a quote

EC PLAZA

South Korea

High frequency welded fin tube extendheat transfer surface that provides maximum efficiency in theat exchange applications from exhaust hot gas to a contained liquid process. Both solid and serrated fin tube is used for Heat recovery steam generator, Petrochemical, Boiler Plants, Economnizer, Gas cooler and Heat exchangers in a wide range of applications. Solid fin tube is recommened for contaminated gas streams where oil, coal, wood or other high fouling fuels are used. Serrated fin tube is primarily used in clean streams. Product Specification Bare tube diameter : 15.88 mm ~ 50.8mm Fin pitch : 5 ~ 12 FPI Fin height : 6.35~25.4mml Fin thicknes : 0.3~0.75mm Fim material : Aluminum or Copper Length : 20,000mm(Max.) Our Company First of all, we are very pleased to take the opportunity to introduce you about our company. DRTC is a highly qualified manufacturer of Aluminum fin tubes for AFC and also of Copper Alloy Tube & Pipe and pleasure vessels parts such as tube-sheet.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Good formability and conductivity make our products useful for condenser case products produced via drawing processes. Manufacturers of these aluminum case applications rely on Novelis to provide high-quality aluminum coils or sheet in alloys such as 1050 and 3004. Novelis produces pre-painted aluminum for scales, dials and nameplates in laser engraving quality, in the form of a surface-treated coil or sheet. Specialized coatings are applied by rollers. Printing is possible via standard commercial inks and paints with no special materials required.

Request for a quote

METAWELL GMBH

Germany

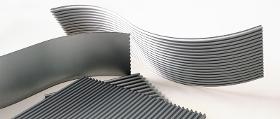

lightweight aluminium panel, where a cover sheet is connected to a corrugated aluminium sheet in a continuous manufacturing process material with highly anisotropic stiffness, resulting in a very simple two-dimensional shaping is possible (see video) simple processing of the material with standard tools high corrosion protection since all used aluminium sheets are pretreated with a primer 100 % recyclable without prior separation of materials. In addition, the proportion of secondary aluminum is approximately 90 %. Easiest forming with Metawell Aluflex Navigation Metawell Aluflex Easiest forming with Metawell Aluflex Design and delivery program Forming parallel to the corrugation Forming vertically to the corrugation Powder-coatable material Video of forming Metawell Aluflex Metawell Aluflex is a material with rigidity levels that depend strongly on the direction. The corrugated sheet is bonded to only one aluminium cover sheet. This structure enables easy 2D-forming and...

Request for a quote

EC PLAZA

South Korea

DHFR A2 is a non-toxic, flame-retardant compound for aluminum composite panels manufactured by uniformly dispersing and impregnating a high content inorganic flame retardant in polyolefin. It is a pellettype compound material that satisfies ‘Fire prevention – European classification of building products’ A2*(DIN 4102) & A2-s1**, d0*** (EN 13501) for Aluminum Composite Panel (ACP). *A2 = Non-Combustible (with combustible components to a minor extent) ** s1 = no/hardly any smoke production *** d0 = no drips/droplets DHFR A2 exhibits excellent flame retardant performance due to its high content of Mg(OH)₂(≥90Wt%) flame retardant and shows processability similar to LDPE due to a balanced combination of raw materials. Due to these characteristics, it is possible to easily produce A2 grade ACP without mechanical supplementation of existing semi-nonflammable (B1;‘difficult to ignite’) materials production facilities (Kneader, Single & Twin Extruder).

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

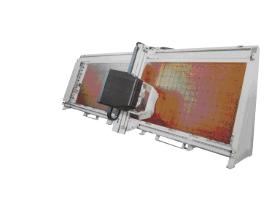

design and manufacture high efficiency aluminum dross recycling equipment for many years, we work with famous American experts in aluminum industry, our main products are dross press, dross pan, cooling head and so on. We have sold our products to NANSHAN, ALBA, ALCOA,DUBAL, HYDRO, KAISER, QATALUM, RUSAL and other famous aluminum companies in the world, our products have obtained high praise from our customers. With unique design, our dross compression unit can cool down the hot dross rapidly, the oxidation and metal loss will be terminated in a very short time. In-house metal recovery could be 30-50%, much higher than any other solutions. We can customize dross press in different types based on your need and your dross amount.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

design and manufacture high efficiency aluminum dross recycling equipment for many years, we work with famous American experts in aluminum industry, our main products are dross press, dross pan, cooling head and so on. We have sold our products to NANSHAN, ALBA, ALCOA,DUBAL, HYDRO, KAISER, QATALUM, RUSAL and other famous aluminum companies in the world, our products have obtained high praise from our customers. With unique design, our dross compression unit can cool down the hot dross rapidly, the oxidation and metal loss will be terminated in a very short time. In-house metal recovery could be 30-50%, much higher than any other solutions. We can customize dross press in different types based on your need and your dross amount.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication for applications where pastes or powders have been used up until now Chain lubrication of heavily loaded chains in temperature ranges in which oil or grease lubrication is not possible For example, in annealing, stoving and baking ovens for aluminium tube manufacturing, in painting systems or in baking lines Advantages and benefits Hygienically harmless as defined in German LFGB Approved by Nuremberg LGA for use in food processing technology NSF H2 registered Economical due to low consumption Optimum wear protection at high pressures and extreme temperatures Can be mixed with water in ratio of up to 1:5

Request for a quote

APD MAQMASTER

Spain

Advancement of the hydropneumatic disc. Protective housing with safety sensor. Cutting speed regulation. Cut at any desired angle between -45° and +45°. Cut right and left at fixed angles 0°, 15°, 22.5°, 30°, 45°. Movable miter that increases cutting capacity. Vertical and horizontal pneumatic clamps. Ø 420 mm cutting disc. Refrigeration system. OPTIONS Single-phase system. Dust extraction system

Request for a quote

APD MAQMASTER

Spain

Hydropneumatic cutting process. Safe cutting with double spring system and disc guard. Vertical and horizontal pneumatic clamps. Shock resistant cast iron bushing. Cut at any angle between -45º and +45º. Cutting speed adjustment according to the profile. Cut with fixed angle of 0o, 15o, 22.5o, 30o, 45o to the right and left. Ø 400 mm disc. Cooling system. OPTIONAL Roller road. Single-phase system.

Request for a quote

APD MAQMASTER

Spain

Length TTRM 1500 = 4050 mm Height TTRM 1500 = 2450 mm Width TTRM 1500 = 1260 mm Horizontal Cut TTRM1500 = 3000 mm Vertical Cut TTRM 1500 =1500 mm Length TTRM 2100 = 5050 mm Height TTRM 2100 = 3100 mm Width TTRM 2100 = 1460 mm Horizontal Cut TTRM 2100 = 4000 mm Vertical Cut TTRM 2100 = 2100 mm Cutting depth 90 mm Disc diameter 350 mm Voltage 230 / 400V – 50 Hz Power 3CV RPM 3000 OPTIONAL Support rollers Probe system for alucobom. Vertical digital display. Horizontal digital display.

Request for a quote

APD MAQMASTER

Spain

MONOBLOCK WORK BASE. Monobloc cutting table construction system without screws or adjustments. MILLS AND CUTS IN THE SAME OPERATION. The TTRM-3x is the only one on the market capable of cutting and milling in the same operation, so the savings in downtime are substantial. IN THE TTRM-3X THE DISCS ARE NOT CHANGED FOR MILLING OR CUTTING. The cutting and milling head internally incorporates the two cutting and milling discs, therefore, no adjustments need to be made between operation changes. ERGONOMIC CONTROL PANEL WITH SELECTOR FOR CUTTING, MILLING OR BOTH SIMULTANEOUSLY. By turning a selector on the control panel, the operation to be carried out is selected without adjustments, without downtime. THE FEELING DISC VERY CLOSE TO THE MILLING DISC. (the distance between the feeler disc and the cutting disc is reduced to achieve simultaneous folding slots of less than 15mm, useful for making curvatures in the panel, etc.) DISTANCE FROM CUTTING DISC TO VARIABLE MILLING DISC.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

APD MAQMASTER

Spain

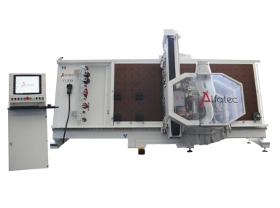

X axis (Longitudinal) 2000 mm Y axis (Horizontal) LEPUS II 4000 mm – LEPUS II L 7000 mm Z axis (Vertical) – without milling 200 mm POSITIONING DISTANCES X axis (Longitudinal) 55 m /dK Y axis (Horizontal) 55 m /dK Z axis (Vertical) 15 m /dK SPINDLE Spindle cooled by 4 fans Maximum power 2.2 kW Maximum rotation speed 18000 rpm ER20 tool holder CONTROL UNIT CNC control Remote network connection, data transfer via Ethernet and USB. OPERATIONAL AREA Dust and chip aspiration system Suction areas in independent spaces Externally controlled vacuum tables LAPUS II 6 – LAPUS II L 8 Automatic tool length measurement Possibility of doing double station processing X axis reference support Y axis reference support LEPUS II 4 – LEPUS II L 9 Metal fences closed on three sides that prevent access to the work area

Request for a quote

APD MAQMASTER

Spain

The PLC 3000 Folder is the ideal solution for those looking to fold aluminum sheet efficiently and accurately. With its ergonomic design and robust construction, this folder delivers exceptional performance in every operation. Thanks to its manual design, the PLC 3000 Folder gives the operator complete control over the folding process. Its ease of maneuver allows quick and precise adjustments, guaranteeing bends with constant and uniform radii on the 1.2 mm aluminum sheet. The PLC 3000 Folder is equipped with features that improve its performance and facilitate its use. Its sheet metal clamping system ensures a firm and stable fixation during folding, preventing slipping and ensuring consistent results. In addition, it has adjustable length stops, which allows folding with precise and repeatable measurements. These stops facilitate serial work and speed up the production process, saving time and increasing efficiency.

Request for a quote

APD MAQMASTER

Spain

Manual override Folds composite panels quickly and efficiently, reducing downtime. Continuous and equal folds, the design of the folder guarantees uniform pressure along the entire length of the fold, regardless of its dimensions. Manufactured in 4 or 5 meters in length. It can be manufactured to the size desired by the client upon request.

Request for a quote

APD MAQMASTER

Spain

It has a fixed 8-position tool changer and a carriage to which another tool changer can be attached, always with 8 positions. Thanks to its numerous versions, 1500×3000, 1650×4000, 1650×6000, 2000x 4000 and 2000×8000, the PWI has found various applications in the industrial sector, for example in plastics, aluminum and agglomerates in general. Special versions can be supplied for milling and threading steel profiles and/or bars. PWI offers a wide Z to hold i supports and to hold particular profiles. In its complete version with clamps, it allows alternating compounds and profiles, in order to optimize the machine for different applications in a single work environment. This machine is usually chosen for its versatility and speed, with an interpolation of up to 40 m/min. In this case, CADCAM ITALMAC provides this version of CNC with all the DXF and geometric figure import tools, so that the PWI is recognizable compared to other similar machines.

Request for a quote

APD MAQMASTER

Spain

Vertical CNC woodworking machines with closed table. Vertical CNC machines with three, four and five controlled axes equipped with a fixed Bakelite work table. Suitable for any type of processing, recommended for those who work a lot of panels, since the closed top technology allows both suction cup and nesting operations

Request for a quote

APD MAQMASTER

Spain

Three, four and five controlled axis configurations Bakelite work surface Extreme versatility to adapt to different materials such as PVC and plexiglass Working ranges: 3500×1600 – 2000 mm, 5000×1600 – 2000 mm, 6000×1600 – 2000 mm Work areas divided into 6/8/10 vacuum zones, automatically activated by the software according to the dimensions of the processed panels Benefits: Speed and precision in CNC machining of aluminum panels Greater comfort and productivity for operators Significant space savings compared to horizontal machines Versatility to work with a wide range of materials

Request for a quote

APD MAQMASTER

Spain

Fixed Bakelite work table: Robust and resistant, ideal for demanding jobs. Closed table technology: Allows both suction cup and nesting operations, optimizing your workflow. Controlled axes: Three, four or five axes for greater precision and flexibility in your projects. Suitable for any type of processing: Perfect for cutting, milling, drilling and much more. Ideal for working with panels Horizontal CNC machines with a closed table are especially recommended for those working with wooden panels, as the closed top technology allows for safe and precise clamping using suction cups or sockets.

Request for a quote

APD MAQMASTER

Spain

Special aluminum alloy body honed with long-lasting electrostatic paint. Special legs to avoid vibration. Great versatility and easy handling. Upper front template with double copy. The pocketing of any figure can be through without needing to change the machining face. Engine power: 1.5 HP 220/380 V Spindle speed: 15,350 rpm Fresolin diameters: d=5mm D=8mm Milling capacity: 255 x 110 x 130 mm. (X AND Z) Fresolin Ø 5 mm. (1 piece) Service keys Lubrication system Measurement stop equipment OPTIONAL Special copy template

Request for a quote

APD MAQMASTER

Spain

Copying equipment for high production. Vertical and horizontal pneumatic clamps. It consists of 3 motors that can be activated according to the machining needs. Works on 3 faces of the profile in the same cycle without having to rotate the piece. 5 mm Fresolin. Oversized profile supports arm on both sides. OPTIONS Special copy templates. Single-phase system. 8 mm Fresolin.

Request for a quote

APD MAQMASTER

Spain

Multi-channel grooving – regardless of the copying system – with the help of supports. Pneumatic clamps. Cremone with 3 drill, bits for steel reinforcement in PVC. 5mm copy milling cutter. Profile support. OPTIONAL Single-phase system. 8mm copy milling cutter. Refrigeration system.

Request for a quote

APD MAQMASTER

Spain

copy system Drainage system with independent motors Triple bit cremone system Includes profile support. Options Milling for 8 mm Single phase system Milled cooling system

Request for a quote

APD MAQMASTER

Spain

The EM100 Trimming Machine is an industrial machine designed for the perfect finishing of wooden pieces. With this retesting machine you can obtain a precise and clean cut on all your pieces, which will increase the speed of work and allow you to achieve quality finishes. The EM100 has a high-speed circular saw that guarantees a clean and precise cut. In addition, its depth adjustment system will allow you to regulate the depth of the cut according to your needs. It also has a guide stop for a more precise and safe cut. Technical characteristics: Motor power: 2.2 kW Maximum blade diameter: 350mm Blade speed: 4800 rpm Tilt angle: 0° – 45° Maximum cutting height: 100mm Maximum cutting width: 300 mm Weight: 250kg

Request for a quoteResults for

Aluminium manufacturing - Import exportNumber of results

236 ProductsCountries

Company type

Category

- Machines for the manufacture of PVC and Aluminium Doors and Windows (122)

- Control boxes - electric (11)

- Aluminium and aluminium alloys (10)

- Machine tools, metal machining - parts and accessories (6)

- Boring - steels and metals (4)

- Cosmetics (4)

- Turning - steels and metals (4)

- Aluminium wires and cables (3)

- Exterior doors for houses (3)

- Furniture for institutional kitchens (3)

- Pallets (3)

- Structures, aluminium (3)

- Windows, wood (3)

- Aluminium alloys (2)

- Chemicals - Basic Products & Derivatives (2)

- Panels, veneered and plywood (2)

- SMALL METAL PARTS (2)

- Stainless steels (2)

- Tanks, metal (2)

- Aluminium coatings (1)