- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- agitator containers

Results for

Agitator containers - Import export

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRK series geared agitator equipped with a helical bevel geared drive with reinforced bearing can be used for a wide range of applications due to its low installation height. This ow installation height can be achieved thanks to the horizontal position of the drive. The agitator shaft of the GRK series is directly mounted in the hollow shaft of the gear and, upon request, this agitator shaft can be divided by flanged coupling. After assembly of the mixer, the agitator shafts are balanced for concentric run. The GRK series features shaft lengths of up to 6,000 mm and drive ratings of up to 75.0 kW. It has a standard output speed of 1 to 250 rpm. According to the specific mixing task, the GRK series can be supplied with matching mixing elements and various seals. Upon request, we supply the GRK series with frequency controlled drives that have drive ratings of up to 7.5 kW. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The agitator shaft of the GRF series geared agitator is directly mounted in the hollow shaft of the parallel shaft geared drive. Thus, no additional bearing housing is necessary. The gear bearings are adequately dimensioned and fully adapted to the requirements. The GRF series is suited for a wide range of applications thanks to shaft lengths of up to 6,000 mm and drive ratings of up to 75.0 kW. It has a standard output speed of 1 to 400 rpm. The agitator shafts are balanced for concentric run after assembly of the mixer. Upon request, we supply the GRF series with frequency controlled drive that has drive ratings of up to 7.5 kW. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

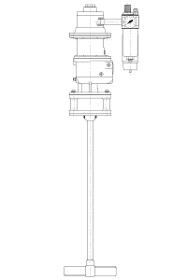

The top-entry agitator LRK is used to meet rigorous requirements regarding both bearing and smooth-running. In addition to its rigid cast steel bearing housing, this agitator series features a coupling housing with an elastic coupling to connect the drive with a shaft journal. Thus, the LRK can be supplied as a fast running agitator with long shafts. The agitator shaft is borne within the bearing housing and is divided by a flanged coupling below the mounting flange. According to your tank size, the LRK series agitator is supplied in six different frame sizes. Shaft diameters of 40 mm to 130 mm with lengths of up to 12,000 mm can be realized. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3). Bearing housings with shaft seals of different materials are feasible, alternatively with stuffing boxes or mechanical seals.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The LRD series top-entry sealed agitator can be used for mixing in closed containers with a mechanical seal. It is designed with a coupling housing. The agitator shaft is borne in the bearing housing and the mechanical seal (single- or double-acting). The seal can be exchanged without dismantling the mixer from the tank (also in case of a side entry). Drives with shaft journals for LRD series: Three-phase motor Helical geared drive unit Parallel shaft geared drive unit Variable speed geared drive unit Helical bevel geared drive unit According to the tank size, the LRD series agitator is available in four different frame sizes. Shaft diameters of 30 mm to 90 mm and shaft lengths of up to 10,500 mm are feasible. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3). Pharmaceutical version with FDA and GMP feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The LRE is the most simple solution of an industrial agitator. It consists of a hollow shaft geared drive (worm geared, parallel shaft geared or helical bevel geared drive) and a rigid cast steel bearing housing. Due to this construction high torques are achieved. The agitator shaft is borne within the gear box and the bearing housing and is divided by a flanged coupling below the mounting flange. According to your tank size, the LRE series agitator is available in four different frame sizes. Shaft diameters of 40 mm to 130 mm with lengths of up to 12,000 mm are realized. Sealing housings supplied with shaft seals in various materials are feasible, stuffing boxes or mechanical seals are an alternative. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRV series can be used in versatile manner. It is equipped with a mechanically variable speed variation drive with drive ratings of up to 11.0 kW. Furthermore it can be supplied with geared drives that have a standard output speed of between 1 and 1,750 rpm. The speed is adjustable with a hand wheel. The agitator shaft of the GRV series geared agitator is directly mounted on the shaft of the mechanical speed variator or with additional speed reduction (all before mentioned solutions possible). The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRV series can be supplied with matching mixing elements and various seals.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRW series is suited for a wide range of applications thanks to shaft lengths of up to 3,000 mm and drive ratings of up to 5.5 kW. It has a standard output speed of between 10 and 200 rpm. Low installation height thanks to horizontal position of the drive. The agitator shaft of the GRW series geared agitator is directly mounted in the hollow shaft of the worm geared drive. Additional flanged or clamp couplings can be implemented upon request. The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRW can be supplied with matching mixing elements and various seals. Upon request, we supply the GRW series with frequency controlled drives.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRS geared agitator is equipped with a helical geared drive suited for a wide range of applications thanks to shaft lengths of up to 2,000 mm and drive ratings of up to 7.5 kW. The GRS series agitators have a standard output speed of 10 to 500 rpm. The shaft mounting options available include sleeve coupling, flange coupling, quick-change coupling or precision-change coupling. The agitator shafts are balanced for concentric run after assembly of the mixer. Upon request, we supply the GRS series with frequency controlled drive. Depending on the specific mixing task, the GRS can be supplied with matching mixing elements and various seals. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

For over 50 years, Geppert Ruhrtechnik has stood for quality and reliability in agitator construction. We develop, manufacture, and distribute innovative agitators for all applications in the materials processing industries, such as the chemical, pharmaceutical, biotechnology, and food industries, as well as in water and wastewater treatment. Our many years of experience make us the perfect partner for both standard and special applications. When selecting and designing our agitators, we draw on our many years of experience, internal databases, and state-of-the-art tools (such as FEM, Finite Element Method, and CFD, Computational Fluid Dynamics), as well as our own fluid mechanical laboratories. This means we always provide you with the optimal solution. In addition to our agitators, we manufacture suitable containers and stands for stand-alone, wall mounted, and mobile designs. We can implement these in your plants, taking into account any its specific requirements.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRP - Pneumatic agitator GRP – pneumatic agitator The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. ((Infotexte)) Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0. The GRP is a pneumatic agitator...

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Radar (FMCW) level transmitter for agitated and corrosive liquids The OPTIWAVE 7400 is a 2-wire 24 GHz radar (FMCW) level transmitter for liquids in harsh environments like tanks with agitators containing corrosive media. It is particularly designed for continuous, non-contact level measurement under extreme conditions prevalent in the chemical, petrochemical or oil and gas industry. The device features Metallic Horn antennas as well as PTFE and PEEK Drop antennas for measuring distances up to 100 m / 328 ft. The Drop antennas are perfectly suited for aggressive liquids in tanks. In applications with toxic and dangerous products, this radar device can be equipped with a Metaglas® second sealing barrier.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling and sealing systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling - Filling station on the module trolley for a quick change and separate cleaning - Hot filling possible - Multi-component filling with different volumes is possible - Optimized filling process by spinning the container - Agitator systems for preventing product separation are optional Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Insertion nozzle movement/ dosing amount adjustment: freely programmable, adjustable intake and dosing time, adjustable return suction - Different dosing technologies are available - Volumetric dosing with auger filler

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling and sealing systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling - Multi-component filling with different volumes is possible - Optimized filling process by spinning the container - Agitator systems for preventing product separation are optional - Synchronization interface for the bottling plant - Adding booklets, leaflets, spoon/spatula or give-aways possible as an option Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Insertion nozzle movement/ dosing amount adjustment: freely programmable, adjustable intake and dosing time, adjustable return suction - Different dosing technologies are available Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-flexofill

Results for

Agitator containers - Import exportNumber of results

15 ProductsCountries

Company type