- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aggregates for concrete

Results for

Aggregates for concrete - Import export

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit table saw blades excel in professional machining of various materials, including tiles, fine stoneware, ceramics, hard stone, marble, exposed aggregate concrete, concrete blocks, and cellular concrete. We even offer a specially developed blade for cutting refractories. Tyrolit combines table saw blades and machines to create system solutions that ensure top results for all cutting operations. This variety and quality make us a valued partner in the construction industry and among professionals who demand precise results. Our table saw blades come in various designs, with SILENT options reducing noise by up to 10 dB, benefiting operator health and motivation. Tyrolit ensures perfect quality and service, offering fast delivery and all relevant blade diameters. High-quality sharpening plates are available for dry-cutting blades.

Request for a quote

RHEIN-CHEMOTECHNIK GMBH

Germany

Liquid stabilizer for control of segregation and sedimentation of high slump concrete and Self Compacting Concrete (SCC). Significantly increases homogeniety of high high slump concrete and Self Compacting Concrete (SCC), avoids sedimentation of fines and segregation of aggregates, facilitates Self Compacting Concrete of high stability and excellent flowability.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Similar to a primary impact crusher a secondary impact crusher (HSI) is a kind of crushing equipment that produces products with a finer more uniform size. Secondary impact crushers are frequently used following the primary crushing stage because they can handle smaller feed sizes than primary crushers. The material enters the crusher and is struck by hammers or blow bars attached to a rotor which breaks the material apart and reduces its size even more. The capacity of secondary impact crushers to produce high-speed impacts that pulverize material into a finer product appropriate for secondary crushing or final applications in a variety of industries is well known. The capacity of Secondary Impact Crushers to generate a variety of products such as fine aggregates sand and finely crushed materials accounts for their adaptability. In industries like mining and recycling or in the manufacturing of asphalt and concrete aggregates where a higher level of product refinement is necessary

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

350-500350-500 tph Dolomite Crushing Screening Plants are modern industrial plants designed to process dolomite ore in order to produce a great variety of dolomite aggregates that are demanded by different construction projects. The abbreviation "tph" itself means the capacity of the plant dealing with the amount of material per hour; therefore, this plant processes 350 to 500 tons of dolomite ore in an hour. Dolomite, the calcium magnesium carbonate mineral, is very essential in the construction industry in making concrete aggregates and road base materials, among other important construction materials. These high-capacity plants play an important role in the crushing and screening of dolomite ore efficiently into specified requirements for construction projects, thereby ensuring a constant supply of superior quality dolomite aggregates for construction applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 50-100 TPH dolomite crushing screening plant is one constructed to process dolomite ore into various sizes of aggregates that are used in the construction. "TPH" represents "tons per hour"; the plant has the ability and capacity to deal with between 50 and 100 tons of dolomite ore every hour. Dolomite is a widely used carbonate calcium magnesium carbonate mineral in construction. Basic work undergone by the plant includes the crushing and screening of dolomite in an efficient manner to produce different sizes of aggregates for its concrete, road bases, and other construction uses.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

These are machines used in construction for the mixing of aggregates, cement, and water to concrete consistency effectively. Cone concrete mixers have a design that ensures a complete turnover of materials to avoid a bad mix of the products. Essentially, these mixers would be very useful on all building sites, in concrete plants, and for industrial purposes since they are effective in producing the desired characteristics of concrete. Overall, cone mixers ease the process of making concrete mixtures and are hence indispensable in the construction field. Their performance is good, they have ease of operations, and they give uniform mixtures, therefore workable tools for professionals in the construction sector. 1. Cone-Shaped Mixing Drum The cone mixer basically consists of a mixing drum, which is cone-shaped in form. It is designed to ensure that aggregate and cement are mixed with water in the correct proportions to produce a homogeneous concrete mixture.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Planetary concrete mixers are one of the most specific mixing machines in the building industry for high-quality concrete mixes. They have a particular design where the mixing blades or paddles are fixed at one end of a vertical rotational shaft that not only rotates around its axis but also in orbit around the middle axis of the mixing bowl. The dual action brings about a planetary mixing action that enables thorough blending of concrete ingredients—cement, aggregates, water, and admixtures. Planetary concrete mixers, therefore, deliver homogeneous mixes of all types because of the sensitive and multidirectional mixing availed by the said action. In this regard, these mixers are well suited for applications that have embraced modern technological mixes requiring uniform concrete mixtures with specific properties.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 700-1000 TPH dolomite crushing screening plant shall be a high-capacity industrial plant built to crush dolomite ore, which can produce all the required aggregates for construction projects. The term "TPH" means how many tonnes of dolomite ore the plant can get through in an hour, which is between 700 to 1000 tonnes per hour. This capability makes it be a core element in vast construction projects that require dolomite aggregates continuously. Dolomite, being of the composition calcium magnesium carbonate, is an essential material for construction, more so in the manufacture of concrete aggregates, road base materials, and other important building resources. These plants thus ensure that dolomite is well processed and sorted out to suit the specifications of construction applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

With its high capacity, the 100 m3/h capacity Dry Type Plant will be able to deliver large volumes of concrete without water in the mix in the beginning. These plants are very efficient in mixing dry ingredients like cement, aggregates, and other admixtures to produce a homogeneous and prime quality concrete mixture. This makes it the right plant to be used for large construction projects that are in dire need of a high output of concrete production. The facility provides accurate weighing and dispensing for dry materials into the batching system in a manner that ensures the correct caliber of aggregates and other components of concrete, hence consistent and reliable concrete production. Water is introduced to the mixtures only in the final mix, starting the cement hydration and yielding a well-mixed mixture suited for many and diverse varieties of construction applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 500-750 TPH Dolomite Crushing Screening Plant is a technology-driven large processing facility meant to provide high-throughput dolomite ore processing into different sizes of aggregates against use in the construction field. The abbreviation "TPH" stands for "tonnes per hour," and it means a plant of this kind can process from 500 to 750 tonnes of dolomite ore every hour. Dolomite plays a key role as a material in the construction industry, mostly produced into concrete aggregates and road base materials, among others of importance. These plants are important for the crushing and screening of dolomite ore into various sizes that would be needed for any specified construction project by providing a steady supply of high-quality aggregates, which are essential in a broad range of applications in the entire construction industry.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 250-350 tph Dolomite Crushing Screening Plants are developed for producing dolomite aggregates of desired sizes required for construction works. In this, "tph" means tons per hour. So, the 250-350 tph dolomite crushing screening plants can handle 250 to 350 tonnes of dolomite ore within an hour. Being the calcium magnesium carbonate mineral, dolomite is no doubt one of the critical materials used in construction processes, in the production of concrete aggregates and various road base materials, among others. Such plants are, therefore, very important in crushing and screening the dolomite ore efficiently to satisfaction on the specific requirements of the construction projects, thus ensuring a constant supply of quality dolomite aggregates for various uses meant for construction.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 150-250 TPH Dolomite Crushing Screening Plant is an installation designed to treat specially dolomite-bearing ore. After processing through crushing and screening, dolomite is produced in different aggregate sizes that find target applications. The abbreviation "TPH" expands into "tonnes per hour," asserting this plant's capacity to treat 150-250 tonnes of dolomite ores on an hourly basis. Dolomite is a type of double-carbonate mineral. Such a composition of calcium magnesium carbonate has immense use, mostly in the construction industry, both of concrete aggregates and in the manufacture of road-based materials. Such plants are involved in the effective crushing and screening of dolomite ore for the production of quality aggregates, which form the fundamental ingredients for infrastructure construction works where supply has to be ensured.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 40-60 TPH dolomite ore crushing and screening plant is a dolomite processing plant, which processes dolomite ore into the required sizes of any kind of aggregate that is used in construction. A TPH is a unit representing tonnes per hour. In this description, the plant has an input capacity to accommodate and treat between 40 and 60 tons of dolomite ore per hour. Dolomite is an important mineral rock that is high in calcium magnesium carbonate and finds much application in the construction industry, particularly in the manufacture of concrete aggregates and road base materials, among other construction-based products.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A basalt crushing and screening plant is a facility that meets the purposes of crushing and screening of basalt stones into aggregate sizes demanded on construction fields, infrastructure, and industry. Basalt is an igneous rock with basaltic features. Large pieces of basalt are broken into smaller ones in the process of crushing, made with such equipment as jaw crushers or cone crushers. After the primary crushing stage, it is separated by sifting in order to segregate the particular material according to size, enabling the production of different sizes of the same material. The efficiency of separation for these highly intermixed crushed basalt materials, in different fractions by size, by the vibrating screens makes them an integrative screen in the process. It is t he enormous product that comes out from basalt\toc crushing and screening plants. It can be used as high-quality aggregate for making concrete, building highways, making gardens, and other constructions that need firm an

Request for a quote

REINFORCED EARTH COMPANY LTD

United Kingdom

Characteristics TechRevetment™ is also flexible in nature and can adapt as per the soil contour of the bank slope or channel bed. The installation process is faster than the conventional concrete or boulder pitching and gabion laying. It delivers the durability and performance of concrete without the costly, time consuming and difficult installation process of a conventionally-formed concrete slope paving. High strength woven geotextile former is used to provide the shape and form. Essential components of the TechRevetment™ system are non-woven geotextiles, geotextile fabric form and fine aggregate concrete. Depending upon the design requirements and specific application, liaison cables can be incorporated in the fabric form. Suitability Underwater installation is one of the various advantages of the TechRevetment™ solution. This provides a unique advantage to the client where dewatering or constructing cofferdams is not possible such as canal bank protection and lining, river bank pro

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK brand SMK Series Secondary Impact Crushers can crush medium and high hardness materials such as limestone, dolomite, granite and basalt to the size of asphalt and concrete aggregate. Large size material from the primary crusher can be fed directly. High reduction rate is provided. It is the most preferred secondary crusher type in crushing and screening plants since the initial investment and operating costs are lower than other crusher types. According to the design of the facility, they can be manufactured as mobile, with fixed steel feet, with fixed concrete feet, with fixed skid chassis, pre-screened or pre-fed.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for transparent universal impregnation to protect absorbent mineral surfaces such as, exposed aggregate concrete, terracotta, natural and artificial rock, granite, brick wall, hard stone, stair stone and for hydrophobing.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PNZ-PRODUKTE GMBH

Germany

Suitable for natural and artificial stone, driveways, terraces, exposed aggregate concrete, garden paths, etc. Terrace and Gravestone Cleaner is an environmentally friendly cleansing extract free of muriatic acid that was specially developed for any kind of stone in garden, terrace or gravestone areas. Removes moss, algae, atmospheric soiling, grease, oil and other contaminants.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for stone Cleaner is an environmentally friendly cleansing extract free of hydrochloric acid and specially made for all stone types in garden, deck and tombstone areas. Appropriate detergent for removal of moss, algae, atmospheric pollution, grease oil and other contaminants on natural and artificial stone, driveways, decks, exposed aggregate concrete, garden paths, etc.

Request for a quote

UMMANMAK

Turkey

The main field of activity of our company is the production of machines that produce products such as paving stones, borders, briquettes, tile stones in various shapes and sizes. These machines are full-fledged concrete block production facilities together with aggregate bins and weighing units, concrete mixers, conveyor belts. Umman Machine uses the high quality products of the leading companies in their own sectors in the manufacture of all machinery and auxiliary equipment. Combining its experience and knowledge of more than half a century with quality raw materials and workmanship, Umman Machine produces our machines and products that will work for many years without any problems and with full efficiency, under the assurance of CE .ISO 9001 2008.TSE, OHSAS. Concrete parquet production

Request for a quote

ENCHO ENCHEV - ETE LTD.

Bulgaria

A variant of a play concrete table with a distinctive focus on the environmentally friendly lifestyle. The seats are made of certified wood, the tabletop and the supporting parts are of high-performance concrete with natural aggregate. The concrete is reinforced and fiber strengthened.The aggregate structure consists of natural marble or granite stones combined in specific colors and sizes. The planks are specially treated, which protects them from rotting and preserves the materials characteristics over time. The table top has a polished surface and the legs supporting the structure are embossed. Chess, Checkers, Backgammon or Ludo fields are made on the table top. Different combinations of games are possible. The colors of the playing fields are determined by the color of the aggregate structure. In order to reduce the deposition of dirt and increase the resistance of the product to aggressive weather conditions.

Request for a quote

ENCHO ENCHEV - ETE LTD.

Bulgaria

Bicycle stand made of high-performance concrete and natural aggregate. The concrete is reinforced and fiber strengthened. The aggregate structure contains natural marble or granite stones. They can be combined in different colors and are of a specific size. The metal components on which the concrete structure is placed are galvanized and powder coated. All other connecting elements are made out of stainless steel. The concrete surface is embossed and additionally protected with a varnish coating. This makes the product even more resistant to aggressive weather conditions. It provides parking for seven bikes and the mounted rings allow locking to the stand. Through its design, the bike rack 166 makes the most of space and follows eco trends for an environmentally friendly lifestyle. Elegant furnishings for office buildings, business centers, schools, universities, metro stations and other public areas.

Request for a quote

ENCHO ENCHEV - ETE LTD.

Bulgaria

Umbrella stand featuring aesthetics and functionality. The umbrella base is made of high-performance concrete and a natural multicolored aggregate. The concrete is reinforced and fiber strengthened. The aggregate structure is made of natural marble or granite stones of a certain size. The concrete is embossed and combined with a metal structure that also offers color variations. The metal is galvanized and powder coated. These technological methods protect it from corrosion and extend its performance. For areas with even more aggressive weather conditions, additional epoxy primer treatment is also available. All connecting elements are from stainless steel. The metal construction is also available in stainless steel. These characteristics guarantee the durability, solidity, safety and long life of the product. An elegant exterior solution for furnishing camping areas, hotels, resorts, holiday villages, beaches and swimming pools.

Request for a quote

ENCHO ENCHEV - ETE LTD.

Bulgaria

Product of Encho Enchev - ETE creative series of play tables. The outdoor table tennis table is made entirely of high-performance concrete and a natural multicolored aggregate. The concrete is reinforced and fiber strengthened. The aggregate structure is made of natural marble or granite stones of a certain size. The table tennis table is standard in size and is conceptually available in blue or green on the game board. The table top and mesh are finely polished and the concrete legs supporting the structure are embossed. All concrete surfaces have protective coating, which makes the product even more resistant to aggressive weather conditions and reduces the deposition of dirt. The metal elements used to secure the table top to the legs are galvanized and powder coated, and all other connecting components are made of stainless steel. Ping-pong table suitable for any home or garden. A product that is timeless.

Request for a quote

BEYAZLI GROUP

Turkey

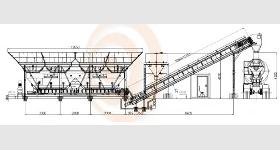

Concrete Batching Plant - Ready Mix Concrete Plant - Concrete Machinery - Concrete Mixer - Concrete Factory |More Economic | Advanced Technology | More Durable | Fast Delivery| Campaign Price: 170.370 EURO (free installation and free staff training) Contact: seher +90 5326382935 (Whatsapp) Warranty: minimum 24 months Capacity: 100 m³ / Hour ready-mix concrete /8 HOURS Transportation : 5 HQ 40' Containers Concrete Batch Plant Ready Mixing Concrete Plant Concrete Mix Machinery Concrete Transportation | More Economic | Advanced Technology | More Durable | Fast Delivery The ready-mix concrete plant or concrete batching plant is designed with a fully automatic operating system. Designed to work 24 hours. This concrete batching plant system is made to produce ready-mix concrete from the mixture of Aggregate, Cement, Water and Concrete additives with specific ratio. The system of concrete batching plant starts operation with the dosage. Video: https://www.youtube.

Request for a quote

TECONER OY

Finland

The sensor is used to measure the moisture of concrete aggregates and is typically installed over a silo belt feeder or a conveyor belt or under a silo trap door to have a view on a moving sample. Current loop is available for feeding the data into your PLC, and a software licence for a PC to calibrate the sensor as well as view and store the data is also included in the system. There are no moving or wearing parts and as the measurement is done by a non-contact remote sensor, the maintenance cost will be very low.

Request for a quote

PI MAKINA

Turkey

Cone crushers are designed to crush hard and a corrosive brook and quarry materials such as granite, basalt, and andesite. It is used as a secondary and tertiary crusher. The maximum input size is 135-215 mm. The principle of operation of cone crushers is to crush the materials with the effect of compression, cutting and bending. It offers low dust and wear-out rates as they crush the material through compression. Thanks to the long-lasting wearing parts, the crushing process lasts longer. By virtue of its advanced crusher chamber design, it provides high productivity with less wear on parts. The adjustable crusher chamber makes it possible to receive material of the desired size. In addition, operating costs are low as maintenance and repair operations can be easily carried out on the crusher.

Request for a quote

PI MAKINA

Turkey

Pi Makina, which has produced the largest Crushing and Screening Facilities in Turkey and the world, produces solutions suitable for every project and need. Pi Makina has installed hundreds of crushing and screening plants around the world and uses its experience in this sector in every new project to offer superior performance facilities tailored to customers' wishes. Pi Makina, which produces any equipment that may be necessary for a crushing and screening plant through its own designs, has a wide range of products such as cone crusher, vertical shaft impact crusher, hammer crusher, jaw crusher, screen sand washer and mobile crushing plant.

Request for a quoteResults for

Aggregates for concrete - Import exportNumber of results

29 ProductsCompany type

Category

- Crushing and grinding machinery (10)

- Concrete preparing - machinery and equipment (5)

- Concrete blocks (2)

- Concrete constructions (2)

- Civil engineering - contractors (1)

- Compactors and crushers (1)

- Concrete mixers (1)

- Concrete products and conglomerates (1)

- Concrete, ready-mixed (1)

- Gaming tables and accessories (1)

- Geotextiles (1)

- Park equipment (1)

- Power saws, portable (1)

- Swimming pools, installations and equipment (1)

- Table tennis - equipment and accessories (1)