- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- valves for gas

Results for

Valves for gas - Import export

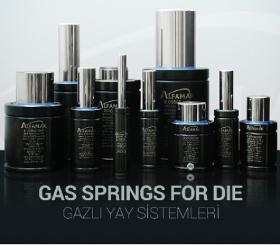

TEMAS GROUP EXPORT PARTNERS

Turkey

ALFAMAK is one of Turkey's leading gas spring manufacturers. Established in 2003, our company has been operating in the industry for 19 years and has gained a reputation for success. Gas spring is a new technology which comes instead of standard steel or polyurethane springs. A gas spring has a container of compressed Nitrogen gas with Piston Rod , Bush, Rod Rings, Valve etc. The Gas Springs are used in Cold Stamping industry to form, cut and fix the sheet metal inside the die. Many auxiliary materials are used for different purposes in the gas spring. Rod wiper, rod guide and rod seal are used on the inner surface of the bush. The purpose of the rod wiper is to prevent the oil and chips in the die from entering the gas spring. The rod guide is used to carry the load in case of axial force on the rod during use. The most important auxiliary material for sealing is rod/piston seal. It directly affects the performance of the product by keeping the gas in the gas spring.

Request for a quote

EC PLAZA

South Korea

1. Features There are additional high performance accessories available convenient applications - Anti-siphon Check Valves - Strainer Foot Valve - Flange Connections, Tees, Elbows 2. Precise Valve Structure The degree of precision is maximized since Double check balls or spring insert type is adopted in valve structure 3. Gas Locking Prevention - Liquid End Design minimizeds dead space. - Air Relief Valve can be provided for vaporous liquid. (optional item for KS 51~32)

Request for a quote

TETHYS OIL SUPPLIES & SERVICES

Malta

Designed to boost your well economics, our gate valves meet API PR2 Annex F operational requirements and are built to withstand the harshest onshore production environments. Leveraging on more than 20 years of field experience with the standard Series100 valves, TechnipFMC’s M120plus gate valve design is developed over 4 years of extensive research and development. Detailed finite element analysis led to development of a lighter, more open valve body which enables better access to the seat pockets for easier, quicker assembly and maintenance. TechnipFMC individually qualifies each gate valve size using nitrogen gas even though API Spec 6A permits qualification by scaling one size above and one size below the tested valve. In addition, TechnipFMC imposes additional performance requirements and endurance testing to simulate 25 years of operation in the field. Also available in “adapted for actuator” configuration for M130Plus model.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Valves for gas - Import exportNumber of results

3 ProductsCountries

Company type