- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal screws

Results for

Metal screws - Import export

OTTO EICHHOFF GMBH & CO. KG

Germany

During re-machining, a cutting tool is used to remove material from a workpiece in order to shape or surface it as required. We offer re-machining (turning, twisting) as wage work. The following machining operations we offer: Turn thin stem, pins and tips Screw punctures, approaches and undercuts Heads of screws / cold shaped parts machining process (turning) further machining operations are possible on request. Our curve-controlled automatic Audrema lathes offer you further possibilities of finishing cold-moulded parts. These automatic lathes are designed to achieve maximum precision and reproducibility at high throughputs. Short loading and unloading times permit economical production of medium-sized and large series.

Request for a quote

METFIX GROUP

Kazakhstan

Roofing self-tapping screw for metal DIN-EN-ISO 15480 (old - DIN 7504-K) with an EPDM washer 2.4-2.8 mm thick Standard Head: hexagonal with a shoulder, , turnkey 8 (D-5.5) or 10 (D-6.3) mm, a marking mark in the form of the letter "X" is stamped on the cap

Request for a quote

METFIX GROUP

Kazakhstan

Washer for roofing screws With EPDM rubber gasket, galvanized / has no official standard The washer for the roofing screw is equipped with an EPDM rubber gasket made of ethylene, propylene, diene, methylene. It is not used without a self-tapping screw. The metal part of the washer is coated with white zinc. When painting the roofing screw, the metal part of the washer surface is painted. Coating of the metal part: white zinc. Gasket material: neoprene or EPDM E - ethylene, P - propylene, D - diene, M - methylene. Attention! The thickness of the EPDM rubber gasket on the washer is 2.4-2.8 mm.

Request for a quote

COLORICIO.SRL

Romania

Round steel / Square steel, Flat steel , L cornier profile , IPE Steel and much more

Request for a quote

SYSKOMP GMBH - EMICO

Germany

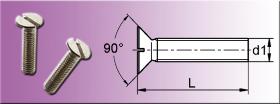

Countersunk screws - metal ~DIN 963 (~DIN EN ISO 2009) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

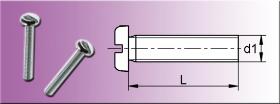

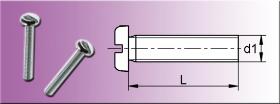

Pan head screws - metal ~DIN 85 (~DIN EN ISO 1580) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

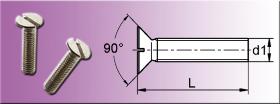

Countersunk screws - metal ~DIN 963 (~DIN EN ISO 2009) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

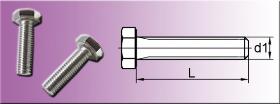

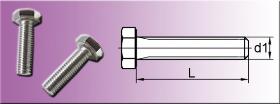

Hexagon head screws - metal ~DIN 933 (~DIN EN ISO 4017, threaded to head) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Hexagon head screws - metal ~DIN 933 (~DIN EN ISO 4017, threaded to head) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Pan head screws - metal ~DIN 85 (~DIN EN ISO 1580) Material: stainless steel A2

Request for a quote

SYSKOMP GMBH - EMICO

Germany

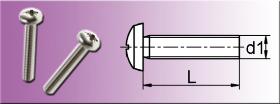

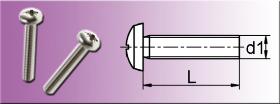

Lens head screws - metal, cross slot ~DIN 7985 (~DIN EN ISO 7045 - form H) Material: machining steel 4.8 zinc-plated

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Lens head screws - metal, cross slot ~DIN 7985 (~DIN EN ISO 7045 - form H) Material: stainless steel A2

Request for a quote

OM GLOBAL TRADE CO. LTD.

Turkey

We provide listed products in specific shapes and specs upon your request: Bolt, nut and screw sets Metal clamps in specific shapes and measurements Steel beam to beam connections in specific shapes and measurements

Request for a quote

ENBI PLASTICS & SILICONES BV

Netherlands

Creating an optimal bond between a metal plate and the silicone: that was the challenge Enbi Plastics was given by Océ Technologies, a major player in printing and copying equipment. They needed a new wiper assy; a part on the print head that prevents streaks on the paper. Because this part needs to be somewhat flexible, silicone needed to be added to a small, punched metal plate, to which screw thread is welded. This construction did not allow for a mechanical bond between the metal and silicone, which meant chemical bonding was the only option. Together with the client, the mould supplier, the silicone supplier and others, we did extensive research into the best way to achieve this bond. It showed that preparing the small metal plates was the key. After several tests, we discovered the optimal way to do this. A number of factors play a role: from how to clean and sand the plate to humidity, temperature and the time in between the steps of the process. Every detail counts!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Metal screws - Import exportNumber of results

17 ProductsCompany type