- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aerosol filling machinery and equipment

Results for

Aerosol filling machinery and equipment - Import export

SMART MAKINA

Turkey

The Working Principle 1st Unit – Rotating Empty Container Feeder : The Unit automatically feeds the aerosol cans onto a conveyor, and the speed can be adjustable. 2nd Unit – Rotating Deodorant Filling – Crimping – Gassing Unit The Unit automatically fills the aerosol product into the cans, crimps their valves, and pumps gas into cans. Empty containers enter the rotating star system one by one to be filled automatically. After the filling process, the operator puts the valves manually on the already filled containers; then, the valves are crimped onto the containers. After the crimping process, the gassing starts. On the 1st gassing station, the container fills half of the container, and the remaining on the 2nd Unit. The reason for the two stations is to make the system faster. After the gassing process, the aerosol cans move on the conveyor until the end of the line to be picked up for boxing.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The automatic Aerosol Filling Machine is composed of a push table, printing machine, automatic filling machine, weighing machine, water leak detector, nozzle machine, capping machine, and workbench. They are suitable for filling all kinds of liquid materials, such as thin liquid (kerosene), thick liquid (facial cleanser, PU foam) etc. Can be used in the food, chemical, pharmaceutical, and other liquid filling industry. The main part(including liquid filling and gas filling and sealing and boost pump) is to adopt pneumatic control.

GERI TRADING SRL

Romania

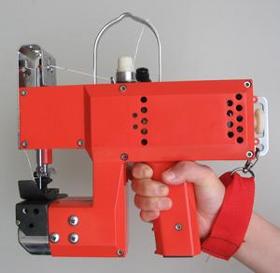

Portable bag closer sewing machine Model : NP-7D (two needles two threads) Brand Keestar (CN) Sewing type : dbl. stitch chain Sewing step : 6,5 mm Sewing speed : 1.250 spm Tension 220V/50Hz Weight 5,8 Kg Cutting the chain : automatic

Request for a quote

GERI TRADING SRL

Romania

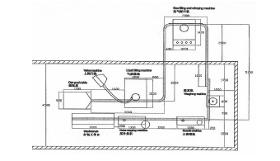

Characteristics : The packed material is of the powder type (flour, malt, etc.). Weighing range: 10 - 50 Kg / bag. Accuracy: ą 0.1% -0.5%. Weighing / packing speed: 240 - 540 bags / hour. Supply voltage: 380V (50Hz).. Optionally the line can be equipped with the following devices: - Bundle printing of the date of validity, packing, lot number, etc. - vertical loader for feeding the silo in which the weighing and filling material of the bags is stored Depending on the specifics of the user, closing of the bags can be done by thermal bonding instead of sewing (specific for packing in transparent polyethylene bags).

Request for a quote

ARSILAC

France

Reference : 007186 Provenance head corker: cork head for easy corking and uncorking of bottles.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GERI TRADING SRL

Romania

The band transport conveyor GKS has a large capacity for bags supply at a high speed bag closer sewing head. This conveyor is part of an automatic line suitable for agriculture sectors where bags packaging and storage are also requested. Whenever such conveyor is working, bring the effortless of operators, while productivity level become higher and packaging cost are decreased. Characteristics : Band length :2,0 - 4,0 m. Band wide :400 mm. Transport speed :6,7 - 22 m/min. Transport capacity :20 - 100 tone/h. Tension :380 V. Motor power :0,55 Kw. Price : from 650 Euroas to the band's length requested.

Request for a quote

GERI TRADING SRL

Romania

Portable bag closer sewing machine Model : GK - 1800 Brand Keestar (CN) Sewing type :chain stitch Sewing step : 6 - 8mm Sewing speed : 1600 spm Tension 220V Weight 3,5Kg Cutting the chain : automatic

Request for a quote

GERI TRADING SRL

Romania

Characteristics : The packaged material is granular (grain, rice, salt, sand, etc.). Weighing range: 1 - 25 Kg / bag. Two weighing tanks (double the weighing speed). Tolerance: 0.2%. Weighing / packing speed: 360 - 900 bags / hour. Supply voltage: 380V (50Hz). Price at request. Benefits : - two weighing tanks that will increase packing capacity and intake Optionally the line can be equipped with the following devices: - conveyor belt with variable length between 2m and 4m. - Bundle printing of the date of validity, packing, lot number, etc. - vertical loader for feeding the silo in which the weighing and filling material of the bags is stored Depending on the specifics of the user, closing of the bags can be done by thermal bonding instead of sewing (specific for packing in transparent polyethylene bags)

Request for a quote

FARK PROCESS

Turkey

The Filling Wizard is a functional filling machine. It has sealing and dating equipments on the machine. Molds are changeable depending to the cup size.

Request for a quote

PACKFEEDER

Spain

The in-Line series from Packfeeder has a wide range of systems and models of machines for unscrambling bottles of different dimensions, characteristics and materials, with speeds that can be adapted to the different production needs. The in-Line Packfeeder bottle sorter system can work efficiently with packages of very different volumes, from small dimensions of 3-4ml to large packages of more than 1L, at a wide range of speeds that can reach 500 u/min. The STD range of the in-Line series is comprised of different sized feeders that adapt to the different volume needs of packages and production speeds. They all provide extraordinary versatility, which allows for them to work with countless products, as they can be configured according to the needs of a wide range of industrial sectors.

Request for a quoteResults for

Aerosol filling machinery and equipment - Import exportNumber of results

11 ProductsCountries

Company type

Category

- Bag filling machinery and equipment (6)

- Bottling and filling - machinery and equipment (5)

- Packing and packaging - machinery and equipment (2)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Dairies - machinery and equipment (1)

- Packaging (1)

- Wine-making - machinery, equipment and plants (1)