- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- additives for printing

Results for

Additives for printing - Import export

KOSA PACK

Turkey

Plastered boxes are a type of box produced by laminating American Bristol cardboard onto corrugated cardboard with the plastering technique. Plastered boxes are used in various sectors. The main feature that distinguishes these boxes from cargo boxes is; It is a packaging solution with higher quality and design value by applying various printing techniques to Bristol paper on which it is plastered. The cardboard on the outer surface is the most important paper that provides resistance to the offset box. The weight of 1 square meter of Bristol or Kroma cardboard varies between 180 grams and 420 grams. After the printing on the cardboard, matt cellophane coating, glossy cellophane coating, UV lacquer or dispersion lacquer process is applied to the cardboard in order not to damage the printing and to ensure the longevity of the box. After these processes are completed, the product that will greet you looks higher quality and more cosmetic than the cargo box.

Request for a quote

RBECO SP. Z O.O.

Poland

E-commerce boxes are an economical and practical solution when it comes to packing products for shipping. We offer boxes in various sizes and color variants. They have a convenient closure, and no additional tapes are needed for packaging. The e-commerce boxes can also have a skidding device, which additionally secures the packed products and allows the customer to return in the same box. In addition, we can print a logo or any graphics on the box, thanks to which they can be a great marketing tool. The high quality of cardboard and a professionally made print are a perfect testimony to the durability of the product itself. We also offer exclusive decorative boxes, which are a perfect solution for creating PR packages and creating gift sets.

Request for a quote

GRIST 99 PRINTING HOUSE

Poland

Didn't find the product on the website of our offset printing house in Warsaw ? It's okay - we have presented only the basic Grist99 products above and this is only a part of the many areas of printing in which we specialize. At the special request of our customers , we also realize calendars , roll - ups , business cards , as well as offset printing of stickers on a sheet , including UV stickers . In addition to printing advertising materials, we also print books and magazines in large and small editions. You will find our headquarters near Warsaw - in Blizne Łaszczyńskiego

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

RPWORLD

China

3D printing or additive manufacturing (AM) is any of various processes for making a three-dimensional object of almost any shapes. At RPWORLD, additive manufacturing 3D printing is designed for functional prototypes, complex designs, and production components. - Materials selection Selective laser sintering, (SLS), Stereolithography (SLA) and Fused Deposition Modeling (FDM) are the most common additives manufacturing processes that RPWORLD uses to realize a project. - Cost-efficiently You can get the 3D printed parts of any possible shapes as you desire. And more importantly, since it doesn’t need the mold, it could be a cost-effective process for your custom parts. - Complex-geometries The structure of the 3D printed parts is not limited, you can nearly get any shapes as your part design.

Request for a quote

TURKISH MANUFACTURERS UNION

Turkey

Our company which established in 1995 is a lediang company at the sector with mainly producing wet towels, alcohol wet towels, glass and lens cleaning wipes in addition to stick sugars, printed-unprinted napkins, disposable shampooes, hand, face suncreams. Our products can be prepared with private label according to the clients requests. We serve the best quality to clients by receiving their confirmations at all periods of the operations like design, production and delivery. Mission : To have customer loyalty and totally meet customers requests and expectations by developing our products and service continually. Vision : To be leading confidentual and reputable company of the sector by increasing national & international reputation, efficiency and productivity of our company . Values : Customer Orientation, leadership, reliability, innovativeness, effective communication, perfectionist, liability, transparency and synergy provided by our products and services ranges.

Request for a quote

TURKISH MANUFACTURERS UNION

Turkey

Our company which established in 1995 is a lediang company at the sector with mainly producing wet towels, alcohol wet towels, glass and lens cleaning wipes in addition to stick sugars, printed-unprinted napkins, disposable shampooes, hand, face suncreams. Our products can be prepared with private label according to the clients requests. We serve the best quality to clients by receiving their confirmations at all periods of the operations like design, production and delivery. Mission : To have customer loyalty and totally meet customers requests and expectations by developing our products and service continually. Vision : To be leading confidentual and reputable company of the sector by increasing national & international reputation, efficiency and productivity of our company .

Request for a quote

TEMCA GMBH & CO. KG

Germany

Extremely tear-resistant, abrasion-proof and robust wipe (cellulose-polyester-mix) with creped surface. Turquoise. Very absorptive and hard-working (high mechanical stressing). Resistant to solvents, squeezable and for multiple uses. profix® escon crêpé performs all positive features of profix® escon print. In addition to this the creping increases the surface of the material which results in a softer material and an improvement of absorption capacity and absorption rate. Main Fields of Application: Multi-purpose-wipe for highest demands on low-linting and tear-resistance. As degreasing wipe in automotive and in paint shops, workshops, production plants engineering and transmission manufacturing. In printing industry for cleaning of press cylinders. Abrasion-proof, Absorptive, Capable of oil absorption, Low-linting, Resistant to solvents, Tear-resistant, Water absorption capacity

Request for a quote

TEMCA GMBH & CO. KG

Germany

Extremely tear-resistant, abrasion-proof and robust wipe (cellulose-polyester-mix) with creped surface. Turquoise. Very absorptive and hard-working (high mechanical stressing). Resistant to solvents, squeezable and for multiple uses. profix® escon crêpé performs all positive features of profix® escon print. In addition to this the creping increases the surface of the material which results in a softer material and an improvement of absorption capacity and absorption rate. Main Fields of Application: Multi-purpose-wipe for highest demands on low-linting and tear-resistance. As degreasing wipe in automotive and in paint shops, workshops, production plants engineering and transmission manufacturing. In printing industry for cleaning of press cylinders. Abrasion-proof, Absorptive, Capable of oil absorption, Low-linting, Resistant to solvents, Tear-resistant, Water absorption capacity

Request for a quote

TEMCA GMBH & CO. KG

Germany

Extremely tear-resistant, abrasion-proof and robust wipe (cellulose-polyester-mix) with creped surface. Turquoise. Very absorptive and hard-working (high mechanical stressing). Resistant to solvents, squeezable and for multiple uses. profix® escon crêpé performs all positive features of profix® escon print. In addition to this the creping increases the surface of the material which results in a softer material and an improvement of absorption capacity and absorption rate. Main Fields of Application: Multi-purpose-wipe for highest demands on low-linting and tear-resistance. As degreasing wipe in automotive and in paint shops, workshops, production plants engineering and transmission manufacturing. In printing industry for cleaning of press cylinders.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

RPWORLD

China

Stereolithography (SLA or SL; also known as optical fabrication, photo-solidification, solid free-form fabrication and solid imaging) is an additive manufacturing or 3D printing technology used for producing models, prototypes, patterns, and production parts up one layer at a time by curing a photo-reactive resin with a UV laser or another similar power source. How Does SLA Work? Firstly, the SLA machine starts to draw the support structures layer by layer. The part itself is followed with an ultraviolet laser aimed onto the surface of a liquid thermoset resin. Secondly, when a layer is imaged on the resin surface, the build platform shifts down and a recoating bar moves across the platform to apply the next layer of resin. The process is carried out layer by layer until the build is done.

Request for a quote

DRESSLER GROUP

Germany

Two current examples of Dressler Group innovations: Spherical Powder Technology (SPT) and the development of integrated processes. SPT is a process that allows powders to be made out of high-performance polymers that cannot otherwise be pulverised. This opens up completely new kinds of applications, using processes such as 3D printing/additive manufacturing, that were equally impossible before. Meanwhile, integrated processes allow grinding, sieving and dust removal to be carried out in a single operation rather than separate steps, thus saving energy and time.

Request for a quote

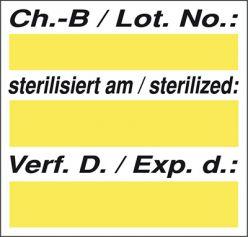

METO INTERNATIONAL GMBH

Germany

Meto sterilisation labels to indicate that medical instruments have been sterilised. Identification, monitoring and documentation with a label. Meto sterilisation labels facilitate reliable process control for medical sterilisation using steam, ethylene oxide and gamma rays thanks to a permanent change in the colour of the indicator ink. It is also possible to print out additional data such as the steriliser, person responsible, date, batch number and use-by date.

Request for a quoteResults for

Additives for printing - Import exportNumber of results

58 ProductsCountries

Category

- 3D printers (17)

- Prototypes, industrial (6)

- Extrusion - steel and metals (2)

- Models for the building industry (2)

- Printing (2)

- Silicones (2)

- Textile - import-export (2)

- Boxes, cardboard (1)

- Custom packaging (1)

- Engines & Parts (1)

- Freeze drying - machinery and equipment (1)

- Labels - stationery (1)

- Lamination - paper and cardboard (1)

- Laser printing (1)

- Marking - diverse products (1)

- Milling - steels and metals (1)

- Offset printing (1)

- Optical measuring equipment (1)

- Packing and packaging materials, metal (1)

- Paper, stationery - manufacture (1)