- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ac servo motors

Results for

Ac servo motors - Import export

FÖHRENBACH GMBH

Germany

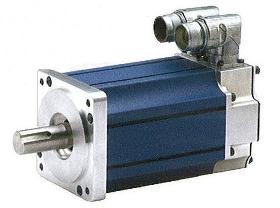

2-phase stepper motors Our 2-phase stepper motors are reliable and low-cost drives with a long service life. They are available in different sizes and types of power output, are continuously developed and are thus suitable for a variety of applications. AC servo motors The AC servo motors meet the highest demands regarding dynamics and accuracy and are used if dynamic, exact positioning or smooth running characteristics are required. The different types of power output and sizes cover the most diverse requirements. The benefits at a glance Highly dynamic High efficiency Long service life

Request for a quote

GSW SCHWABE AG

Germany

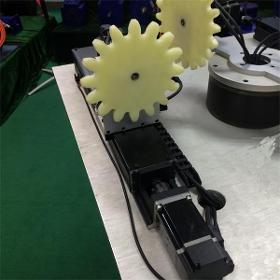

High feeding accuracy, quick cycles and simple operation Servo feeding in compact design with maintenancefree AC servo motor Fits just about any press +/ 0,025 mm feeding accuracy through incremental servo encoder Lightweight rollers with special hard chrome layer Mechanical pilot release Sturdy steel plate bolton design Height adjustment via threaded spindle Catenary rolls and edge guides at machine entrance Stock guides at exit Highperformance control with good functionality; with remote control for setup on 3,5 m cablel 24 V DC proximity switch adjustable piloting lever to be mounted to press pneumatic pilot release

Request for a quote

EC PLAZA

South Korea

MIRHO Corporation make an industrial CNC in person in Korea, called G-Aid, also using for education , industry, dental purpose. We are introducing our signature product, Smart Milling Machine G AiD. G AiD is high speed milling machine for more precise machining. It has comparable six features with another CNC. - Control axis : simultaneous 4 Axis - Spindle : Max 30,000RPM 3.6kW - ATC : Tool detect sensor 7ea, Ф6 - Material : Titanium, Industrial Ceramic, Aluminum, Sus, Steel, SiC, Carbon, ALN, Etc. - Motor : AC servo with IP67 absolute system - Working Area : 100*100 mm - Power Requirement : CE, KCs - Weight : 336kg - External Dimensions : 600*780*1800 mm Feature 1 is "Multiple Jig Solution". Features 2 is "Optimized Motion Controller". Features 3 is "Easier User Interface". Features 4 is "High Speed Milling". Features 5 is Automatic Tool Length Measurement". Features 6 is " Optimized Footprint and Low-Cost High Efficiency".

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

The igm compact systems are optimized for arc welding applications in all mechanical aspects as well as the control hardware and software. In this combination of work piece and robot peripherals, the entire system is kept compact, since the robot changes workstations simply by pivoting the rotary arm or - in other configurations - the work station cahnes is performed by a rotary table. The drive is axis-controlled and provided by an AC servo motor with a special gear box and a built-in digital encoder. The turning fixture is perfect for use as an external robot axis. Work piece movement is completely integrated in the robot control system and permits synchronized movement of the work piece during the welding sequence. The programming takes place simple via the teach pendant K6. All necessary control components for manual and automatic operation are integrated in the system. Examples for igm compact systems and complete welding cells igm compact systems, type RSX 501, 502, 1001,...

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

More than 40 years experience in the development of welding robots and planning of production plants appear in a extensive range of system modules. The main module is the igm robot series RTE 400. Benefits, typical for igm robots: Outstanding programming techniques with both the K6 programming teach pendant and the offline teaching system. Large work zone and perfect welding access to seam positions due to an optimal axes geometry and mounting of the welding torch in the wrist axis, implemented as a hollow shaft. All cables are inside the robot arms using hollow shafts. The particular features of the RTE 400 modular robot system are the extremely slim robotic arms, optimized for weight and rigidity. For axes 2 and 4 there are available different lengths, the right range of movement can be selected for any application. The highly dynamic, maintenance-free AC servo motors and outstanding characteristics of the joint construction of rigid cast aluminium guarantee a high rotational...

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-H5 (H) is a compact, high-speed handling robot for small loads. A larger free space in the area of the joint creates a large arm space. Like all robots in the FD series, the H5 model also has collision protection through improved fault detection / elimination. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data: Number of axes: 6 Working range (P-Point): R 866 mm Max. payload capacity: 5 kg Positional repeatability: +/- 0.05 mm Drive System: AC Servo Motor Drive Power: 1440 W

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V166 is extremely efficient when handling heavy weights (up to 166kg). Like all robots in the FD series, the FD-V166 also has collision protection through improved fault detection / elimination. Thanks to the easily accessible cable routing, the V166 is very easy to maintain. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 166 kg Working Range (P point): R 2654 mm Positional repeatability: +/- 0.1 mm Drive system: AC servo motor Drive power: 18000 W

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V210 is extremely efficient when handling heavy weights (up to 210kg). Like all robots in the FD series, the FD-V210 also has collision protection through improved fault detection / elimination. Thanks to the easily accessible cable routing, the V210 is very easy to maintain. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 210 kg Working Range (P point): R 2674 mm Positional repeatability: +/- 0.15 mm Drive system: AC servo motor Drive power: 18000 W

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V6S has an extended degree of freedom which enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several of the FD-V6S robots can be placed closer together in manufacturing cells, which simplifies an increase in the number of robots per component. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1427 mm Max. payload capacity: 6 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3600 W. Weight: 178 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V6LS from the FD series impresses with its slim design and an expanded degree of freedom, which enables a constant torch orientation when immersing in tight work spaces. Compared to the V6S, the V6LS has an extended arm, which is why the range is increased again. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2006 mm Max. payload: 6kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6000 W Weight: 316 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding / handling robot FD-B6 with integrated cable routing and further developed design is designed for all welding tasks and payloads up to 6 kg. Even the connections and cables required for the SynchroFeed welding process are pre-installed. Thanks to higher process speeds and shorter cycle times, the FD-B6 fulfills all requirements for the most demanding handling tasks. • Higher clock speeds for highest industrial speeds • Slim design: Integrated wrist motors prevent malfunctions from devices and workpieces. • User-friendly: Integrated supply lines prevent faults behind the robot arm. • More stable construction: 1.5 times the load capacity for welding tasks with different ranges. Number of axes: 6 Max. payload capacity : 6 kg Working Range (P point): R 1445 mm Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3132 W Weight: 145 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V50 has the highest efficiency when handling medium loads (up to 50 kg). Like all robots in the FD series, the FD-V50 also has collision protection through improved fault detection / elimination. Comparatively minimal footprint with a maximum working area. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. On request also with the improved protection class IP67. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 50 kg Working Range (P-point): R 2050 mm Positional repeatability: +/- 0.07 mm Drive system: AC servo motor Drive power: 14750 W Weight: 640 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

With its increased payload, this mid-range handling robot is suitable for a wider range of applications. This new solution for your handling tasks has been completely improved in terms of performance. Faster cycle times: Designed for highest industrial speeds. Rugged construction: The robot is built in splash-proof and dustproof design according to protection class IP64. User-friendly operation: The integrated signal cables and air hoses are designed for different connections. Stronger structure: The maximum payload of this new robot has been increased by 25 % to a total of 25 kg. Ideal for a wide range of handling tasks. The main technical specifications at a glance: Number of Axes: 6 Working Ranger (P-Point): R1710 mm Max. payload capacity: 25 kg Positional repeatability: +/- 0,07 mm Drive System: AC Servo Motor Drive Power: 5600 W Weight: 278 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding / handling robot FD-B6 with integrated cable routing and further developed design is designed for all welding tasks and payloads up to 6 kg. Even the connections and cables required for the SynchroFeed welding process are pre-installed. Due to its outstanding arm length, it is particularly suitable for large work areas • Higher clock speeds for highest industrial speeds • Slim design: Integrated wrist motors prevent malfunctions from devices and workpieces. • User-friendly: Integrated supply lines prevent faults behind the robot arm. • Suitable for up to 6 kg payload capacities. Ideal for corresponding handling applications. Number of axes: 6 Max. payload capacity : 6 kg Working Range (P point): R 1445 mm Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3132 W Weight: 278 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4S from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1435 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3550 W Weight: 189 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V20S from the FD series is the optimal robot for medium-heavy loads. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1710 mm Max. payload: 20kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6600 W. Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4LS from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. In addition, the FD-B4LS offers an extended arm compared to the FD-B4S and thus a larger working radius. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2008 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 5650 W Weight: 321 kg

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot FD-V8L with a refi ned design can handle all welding tasks and payloads of up to 8 kg. Due to its outstanding arm length, it is particularly suitable for large working areas. Faster cycle time: Designed for highest industrial speeds. Slim Design: Thanks to the slimmer lower arm design, less rotary motion is needed to reach the working position, thus preventing collisions with jigs and workpieces. User-friendly operation: Even the cables required for SynchroFeed are integrated into the lower arm, which prevents interference behind the robot arm. Stronger structure: Maximum payload now up to 8 kg. The use of different torches and sensors is possible. The main technical specifications at a glance: Number of Axes: 6 Max. payload capacity: 8kg Working Range (P-Point): R2006 mm Positional repeatability: +/- 0,08 mm Drive System: AC Servo Motor Drive Power: 5000 W Weight 273 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

With repetition accuracy of up to ± 0.07 mm, the new high accuracy robot can succeed in even the most demanding of tasks. The deviation from circular diameters of ≤ 10 mm is max. 0.09 mm - half as much as with commercial robots. • Position Accuracy: Highest precision regardless of robot position. • Precision machining: The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The main technical specifications at a glance: Number of axes: 6 Working Range (P-Point): R 1664 mm Max. payload capacity: 20 kg Positional repeatability: +/- 0,08mm Drive System: AC Servo Motor Drive Power: 7900 W Weight: 355 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot, FD-V8, is equipped for all welding tasks and for load capacities of up to 8 kg. Thanks to integrated cable routing, the FD-V8 can still weld much more interference-free than any other robot in its class. It is 15% faster and the cycle times are accordingly shorter - ideal for maximum productivity. Interference-free: Interference-free welding thanks to integrated cable routing SynchroFeed-ready: Cables for the SynchroFeed / Servo-torch system can be integrated into the robot. Robot distances: Integrated cable routing enables reduced distances between the robots. Increased payload capacity: Higher load capacities of up to 8 kg. Higher performance: Up to 15% higher speeds. The main technical specifications at a glance: Number of axes: 6 Max. payload capacity: 8 kg Working Range (P point): R 1437 mm Positional repeatatbility: +/- 0.08 mm Drive System: AC Servo Motor Drive power: 3016 W Weight: 140 kg

Request for a quote

PJM MECHANICAL CO.,LTD

China

Voltage: 220V No.s of Poles: 8 No.s of encoder lines: 2500 PPR Rated Speed: 3000 RPM Rated torque: 1.27-2.4 N.M Work temperature: -10-55℃ Insulation Class: H CNC motor,Semi conduct motor,Military motor,Aerospace motor,Industrail automation motor.Application:Advertisement and engraving,wood engraving,digital control machine-tool,line cutter,ultrasonic welder,water cutter,optical fiber glass stretcher,gantry crane system,food processing,package printing

Request for a quote

PJM MECHANICAL CO.,LTD

China

Voltage: 220V No.s of Poles: 8 No.s of encoder lines: 2500 PPR Rated Speed: 3000 RPM Rated torque: 1.27-2.4 N.M Work temperature: -10-55℃ Insulation Class: H CNC motor,Semi conduct motor,Military motor,Aerospace motor,Industrail automation motor.Application:Advertisement and engraving,wood engraving,digital control machine-tool,line cutter,ultrasonic welder,water cutter,optical fiber glass stretcher,gantry crane system,food processing,package printing

Request for a quote

PJM MECHANICAL CO.,LTD

China

CNC motor,Semi conduct motor,Military motor,Aerospace motor,Industrail automation motor.Application:Advertisement and engraving,wood engraving,digital control machine-tool,line cutter,ultrasonic welder,water cutter,optical fiber glass stretcher,gantry crane system,food processing,package printing,paper board transport,textile print and dyeing,artificial chew simulator,blood tester,CAT scanner,DNA tester,pacemeter,robot

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Yaskawa motors,drivers,PLC and I/O boards are used in various different industries in order to maintain continous production.

Request for a quote

PL CONTROL LTD.

Bulgaria

PL Control Ltd has successfully marketed various automation components widely used in the industry, and our experience in the drive and control equipment market has shown that the price -quality ratio is one of the most important in making specific decisions in automation. Our products are optimum in terms of opportunity, with reasonable prices, representing an excellent alternative to the products offered by other leaders in the industry.

Request for a quote

DANTECHS

Turkey

Providing high quality service and products Spare parts for all kinds of industrial facilities as automation and mechanical Supplying obsolete automation components for facilities Competetive prices for actual version of automation compenents by the helping of England office of Dantechs Machine building including robotic applications

Request for a quote

PL CONTROL LTD.

Bulgaria

PL Control Ltd has successfully marketed various automation components widely used in the industry, and our experience in the drive and control equipment market has shown that the price -quality ratio is one of the most important in making specific decisions in automation. Our products are optimum in terms of opportunity, with reasonable prices, representing an excellent alternative to the products offered by other leaders in the industry.

Request for a quote

DELTA LINE SA

Switzerland

Delta Line has been in motion control for more than 40 years and has first-hand experience garnered from their popular brushless slotted motor line. Flexible, configurable and price-practical, these Servo Motors have been eagerly awaited by applications all over the world. While global supply chains continue to be sluggish and delayed, Delta Line has been able to maintain reduced lead times on most of its products helping clients ease their time to market. The Delta Line Servo Motor Family is available in 6 Frame sizes from 38 mm square up to 130 mm square with rated torque ranges from 0.16 Nm to 14.3 Nm. Each of the six frame sizes is available in a low voltage (optimized for 48 VDC) and medium voltage (optimized for 220 VAC) version. Brake and encoder options can be selected. Delta Line extends their famous design flexibly to their new Servo Motor Line where they can engineer custom windings, face mounts and custom keyways.

Request for a quoteResults for

Ac servo motors - Import exportNumber of results

36 ProductsCountries

Company type

Category

- Electric motors - aC (11)

- Welding robots (9)

- Automation - systems and equipment (8)

- Driveshafts and micro-motors - electric (2)

- Industrial robots (2)

- Electric motors - dC (1)

- Electric motors and parts (1)

- Electrical & Electronic Components (1)

- Metal straightening machines (1)

- Milling - machine tools (1)

- Textile finishing - machinery and equipment (1)