- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- abrasion-resisting materials

Results for

Abrasion-resisting materials - Import export

IGUS® GMBH

Germany

igus® presents world's first tribological 3D filament for 3D printers. The tribological 3D printing material is up to 50 times more abrasion-resistant than conventional 3D print materials igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. Real useable parts can now be produced for prototyping. At the moment we offer two materials: the highly wear resistant iglidur® I170-PF and the flexible iglidur® I180-PF. igus®' 3D printer material starter kits are now available in weights from 25 g and diameters of 1,75 mm - 3 mm. Typical applications:Prototype construction, small batches, test installations Delivery program: Delivery program: Wear linear: v= 0,1 m/s; p= 1 MPa; l= 5 mm Wear pivoting: v= 0.01 m/s; p= 1 MPa; ß= 60 igus® presents world's first tribological 3D filament for 3D printers. The tribological 3D printing material is up to 50 times more abrasion-resistant than conventional 3D print materials igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. Real useable parts can now be produced for prototyping. At the moment we offer two materials: the highly wear resistant iglidur® I170-PF and the flexible iglidur® I180-PF. igus®' 3D printer material starter kits are now available in weights from 25 g and diameters of 1,75 mm - 3 mm. Typical applications:Prototype construction, small batches, test installations igus® presents the first tribo filament for 3D printers The new 3D printing materials are up to 50 times more abrasion-resistant than conventional 3D print materials. Complete processing instructions for iglidur® I170-PF (PDF) Complete processing instructions for iglidur® I180-PF (PDF) iglidur® |180-PF Hotend temperature: 220 - 250 °C Bed temperature: 90 - 110 °C Excellent wear behaviour Material table Colour white Moisture absorption at 23 °C and 50 %r.h. 0,3 weight-% Max. water absorption 0,9 weight-% Max. long term application temperature +80 °C Max. short term application temperature +90 °C Minimum application temperature -40 °C Delivery program: iglidur® |170-PF Hotend temperature: 220 - 250 °C Bed temperature: 90 - 110 °C Outstanding wear behaviour of the tribo filaments Harder to process Material table Colour yellow Moisture absorption at 23 °C and 50 %r.h. 0,5 weight-% Max. water absorption 1,6 weight-% Max. long term application temperature +75 °C Max. short term application temperature +85 °C Minimum application temperature -40 °C Delivery program: Y = rate of wear [µm/km] * moulded Wear linear: v= 0,1 m/s; p= 1 MPa; l= 5 mm Y = rate of wear [µm/km] * moulded Wear pivoting: v= 0.01 m/s; p= 1 MPa; ß= 60

Request for a quote

IGUS® GMBH

Germany

iglidur® clip bearing, metric d1 [mm]: iglidur® clip bearing, inch d1 [inch]: iglidur® clip bearings are especially intended for the shaft bushing through plates. For this reason the bearing has a flange on each of the two front sides. After the clip-on the bearings are secured on both sides in the plate. The clip bearings have chamfered slot on the side that enables the mounting of the bearing on one side. After the mounting the bearing straddles and lines the bore in the plate. The shaft prevents the clip bearing from slipping out of the bore. The bearing cannot slip out of the bore even in axial movements. Extremely simple mounting through lateral slot Maintenance-free and self-lubricating Good flexibility in punch hole Good abrasion resistance Quiet operation Suitable for rotary and linear movements Extendibility through the slot Undetachable through double flange Special dimensions possible Plate thicknesses from 3 mm to 4 mm available from stock Material: iglidur® M250 Special properties of the iglidur® clip bearings iglidur® clip bearings are made from the most abrasion-resistant material, iglidur® M250. iglidur® M250 is a bearing material for rugged, wear-resistant bearing systems for medium loads. The bearings are self-lubricating and can be used dry. If required the bearings can also be lubricated. The material iglidur® M250 is resistant to all common lubricants. The iglidur® clip bearings are the ideal solution for bearing functions with low loads. The easy mounting makes it ideal for applications with difficult bearing locations. Compressive strength The permitted static surface pressure of iglidur® M250 amounts to 20 MPa at room temperature. Due to the good adaptability to uneven surfaces of the bearing housing, a high pressure load capacity of the clip bearings persists even in punched holes. For the most small bearing surfaces, the good vibration dampening properties and the insensitivity to misalignment are of primary importance. Surface speeds Clip bearings are particularly wear resistant in slow rotating, oscillating and axial motions. You can find the maximum gliding speeds for the various motions for the iglidur® M250 material under the materials data link shown below. A lubrication at installation or continuous lubrication raises the permitted surface speeds. Clip bearings are available from stock in dimensions of 3 to 25 mm. Fixation Triflex RS For mounting, the bearings are laterally pressed together with the large flange. The chamfered slot makes the bearing spiral-shaped, whereby it can be easily inserted in the plate. The remaining slot in the attached clip bearing can compensate for linear expansions of the circumference. Thus narrow bearing clearances are possible with clip bearings. The bearing clearance is dimensioned in such a way that in a housing bore with a nominal diameter, a shaft made with the same nominal diameter turns easily. The clip bearing can be used in H-tolerance housings up to H13. The turning of the clip bearing in the bore is also permitted. Operating temperatures The wear resistance of the iglidur® clip bearings are excellent with operating temperatures till 80°C. Even at low temperature the bearings remain elastic and abrasion resistant. When to use it? When a sheet metal feedthrough is required When the bearing should be captively clipped on in a drill hole with rough tolerance For rotating, linear and pivoting movements When a quick-mounting bearing solution is sought Clip bearings application examples When not to use it? When constant temperatures of more than +80°C occur iglidur® G When a high-precision bearing is needed iglidur® J When the housing bore is more than 4 mm long iglidur® Clips 2 iglidur® MKM When very high surface pressures occur iglidur® G iglidur® clip bearing, metric d1 [mm]: iglidur® clip bearing, inch d1 [inch]:

Request for a quote

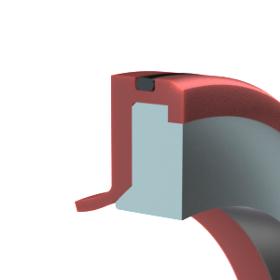

IDG-DICHTUNGSTECHNIK GMBH

Germany

Applications at high speed and low pressure. With O‑ring as secondary seal for sealing in the groove base. Hygienic design without undercuts. No sump formation in front of the seal. Reduced heat buildup due to special lip design. Pressureactivated seal energization. The integrated wedge prevents the sealing lip turning inside out. Very long seal life due to high abrasion resistance. Material only generates low frictional force. Sealing lip does not stick to the mating surface even after prolonged shutdown

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KME series was developed as a wet-installed centrifugal immersion pump for stationary use in tanks and basins. The direct-coupled pump with plain bearings is suitable for pumping and circulating neutral and chemically aggressive liquids in the chemical industry and process engineering, in electroplating and surface technology, in washing systems and water treatment plants, for sump drainage in industrial and municipal waste disposal plants or as a circulation pump in gas scrubbers and heat exchangers. * with various plain bearing designs * available in immersion depths from 600 - 1500 mm Features & Advantages * Compact dimensions * Abrasion resistant material combinations possible * Extremely low-vibration and low-wear operation * All wetted parts made of corrosion resistant plastic * Self-centering alignment in the bearing shell

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: Multipurpose layflat hose in polyurethane Layflat hose for the delivery of liquids under pressure and for transport of abrasive materials, superior abrasion resistance, extremly hardwearing and durable for long service life, resistance to oil, fuel and a wide range of chemicals, excellent flexibility at low temperature

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Welded structure from steel sheets. They are mounted on the shaft in the housing two discs to which clamp hammers are attached. Crusher inside it is lined with carpet, in the lower part with grates, and a gap between them allows the crushed material to move downwards at an appropriate level granulation. The hammers, grate and carpets are made of material abrasion resistant. The hammers on the discs are mounted oscillatingly.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Cortec CorrNetting is a specialised tubular netting designed for corrosion protection of metal surfaces. It employs a proprietary Cortec VpCI formula releasing corrosion inhibiting vapours to safeguard enclosed metal.Unlike traditional methods, this netting offers multi-metal protection, easily applied by cutting and placing around parts.Its VpCI technology provides continuous, long-lasting protection, surpassing temporary moisture-displacement options. The strong polyethylene material resists abrasion and tearing, suitable for rugged environments.While enclosing metal parts may limit visual inspection, the translucent netting allows visibility and easy removal.Compared to desiccants, oils, or VCI papers, CorrNetting offers multi-metal protection, easy application, and long-lasting performance in a compact, reusable format.

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

Flexible continuous-feed belt for hand-guided belt grinders. • Closed coating for high material abrasion • Tear-resistant X-cloth for long lifetime coupled with flexibility • Safe through three full-face fabric layers

FLEXIND B.V.

Netherlands

Construction Transparent polyurethane abrasion and ozone resistant. Application Air, gas, smoke extraction ventilation. Also suitable for extraction of abrasive material good resistance to oil mist.

Request for a quote

TUSKER INDUSTRIAL SAFETY

United Kingdom

Tusker Industrial have produced an extensive range of welding safety gear including high-temperature fabrics designed to protect personnel, plant and equipment. Our industrial welding blankets and industrial fabrics provide solutions to the hazards associated with welding and fabrication and also dust protection, heat protection, sound insulation and chemical protection. Our high-tech materials and blankets can be manufactured to customer specifications, or are available in a comprehensive range of off-the-shelf options.OUR WELDING SAFETY SOLUTIONS Get in touch with our team if you require a solution for: Welding protection (including welding spatter protection, glare and spark protection) Heat retention and heat absorbing materials, thermal insulation and pipe insulation Grinding curtain Heat resistant material Heat reflective material Abrasion resistance Molten metal containment Temperature resistance Dust protection Sound insulation Acid and oil resistance

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Black 60 mit CN-Schicht Applications: Standard quality with extremely high performance in wear resistance. For rough abrasive material and great heights of drop. germanLine® Black 60 shows excellent tear and tensile strengths. Available dimensions: Thickness: 4 / 6 / 8 / 10 / 12 / 15 / 20 mm Width: 1,500 / 2,000 mm Available length: 10 / 20 m Specifications: Colour: black Density: 1.10 ± 0.03 g/cm³ Hardness: 60 ± 5 ° Shore A Tensile strength: ≥ 20 MPa Elongation at break: ≥ 450 % Abrasion: ≤ 90 mm³ at 10 N Breaking force: ≥ 80 N/mm Downloads: Technical Data Sheet germanLine® Black 60 with CN Layer - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Black 60 mit CN-Schicht Applications: Standard quality with extremely high performance in wear resistance. For rough abrasive material and great heights of drop. germanLine® Black 60 shows excellent tear and tensile strengths. Available dimensions: Thickness: 4 / 6 / 8 / 10 / 12 / 15 / 20 mm Width: 1,500 / 2,000 mm Available length: 10 / 20 m Specifications: Colour: black Density: 1.10 ± 0.03 g/cm³ Hardness: 60 ± 5 ° Shore A Tensile strength: ≥ 20 MPa Elongation at break: ≥ 450 % Abrasion: ≤ 90 mm³ at 10 N Breaking force: ≥ 80 N/mm Downloads: Technical Data Sheet germanLine® Black 60 with CN Layer - English [PDF]

Request for a quote

OZPAR KALIP VE KAUCUK SANAYI TIC.LTD STI

Turkey

500x400x50mm Checkered Model Technical Specifications Lenght: 500mm Width: 400mm Wheel Direction High:50mm Colours: Yellow and Black 500mm Yellowx500mm Black as 1000mm End Cap Weight:2 kg Main Body Part:9.50 kg Strenght: Shore A 80+5 Density:ASTM D 1056 kg/m 1.55 Breaking Strenght: ASTM D 412 kg/N 105 Elongation Streching: ASTM D 412 max 210 Working Strenght is made of rubber based material in accordance with its conditions of between -3000 to +70 CO. 4 pieces of end caps are totally 1000mm. Fixed with screws, bolt and dowel to the ground. 12 pieces of m10x100 triphone screws are used in 1 meter of product. PRODUCT SPECIFICATIONS *Produced by impact and abrasion resistant material. *Does not cause any damage to the vehivles with its aerodynamic design. *It doesn’t move from installed ground due to its homogeneous fixing feature. *Producing by rubber material its provides a more flexible slowdown *Colours are black and yellow which in use traffic

Request for a quote

CONTI THERM S.R.O.

Czech Rep.

We also produce hanging suspension tongues for movement of objects of various shapes, sizes and weights. The jaws ensure equal pressure distribution and help transmission of the created clamping force. They are fitted with abrasion resistant material which prevents damage to the surface. Tongues can be operated by hand or pneumatically, depending on the customer´s wish. They are individually designed to fulfill customer specific requirements.

Request for a quote

BLASQEM, LDA.

Portugal

It is an abrasive made from natural minerals, resistant, reusable and iron-free. Hardness: 9-10 mohs Shape: angular Density: 3.2 g / cm3 Welcome to BLASQEM, your Specialist in Shots, Abrasives and Equipment: - Abrasive Products and Accessories - Abrasive steel shots - Abrasives manufacturer - Abrasives solutions - Blasting material - Metallic shots and organic media or glass sandblasting and aluminium oxide or carbon grit abrasive shots for shot blasting - Steel Abrasives and aluminium shot for shot blasting operations - Blasqem is the industry's leading supplier of industrial abrasive

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Abrasion-resisting materials - Import exportNumber of results

17 ProductsCountries

Category

- Wires and cables - ferrous metal (2)

- Abrasive discs (1)

- Fittings, pipe, tube and hose - plastic (1)

- Goods handling systems, continuous (1)

- Metallurgy - machinery and installations (1)

- Natural abrasives (1)

- Nets and ropes (1)

- Pumps (1)

- Rubber - products for the motor vehicle and transport industry (1)

- Sealing rings (1)

- Technical textiles for industrial applications (1)