- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 3d objects

Results for

3d objects - Import export

TECHVIZ

France

A real driver to immersive simulation, TechViz Virtual Assembly option works directly from your native 3D application (like Dassault Systemes Catia V5 or Solidworks HTC Vive), in real time. Compatible with more than 200 3D applications, this VR software solution enables an interactive experience by simulating physical interaction of objects in 3D. Ideal to improve assembly processes, validate maintenance operations or reduce technical risks. TechViz’s Virtual Assembly works with our 3D visualization software TechViz XL. TechViz XL is a virtual prototyping software acting like a driver to capture directly your 3D model. The Virtual Assembly option of this immersive 3D visualization software has a universal part recognition engine that allows part selection and manipulation. Application connectors like CATIA Connector, Navisworks Connector... used in addition to the Virtual Assembly option provide with part information, as they are defined in the PLM database.

Request for a quote

SIM AUTOMATION GMBH

Germany

Entire system solution from a single source: — from construction of the laser cell to integration of your chosen KEYENCE laser — self-contained and high-performance solutions for laser labeling small batches of individual parts Additional possibilities with the SIM-Marker Plus: — Focal point height adjustable within a range of 42 mm (±21 mm) — Autofocus with 3-axis laser control (simultaneous control of the X, Y and Z axes of the laser optics) — Distortion-free marking of 3D objects such as bevels, cylinders, spheres and cones — Set up: directly on a desk or mounted onto the movable base frame — Latest three-axis laser marking systems offers a laser labeling system that can be precisely adjusted to the materials and part geometries that shall be labeled Advantages of integrated optical three-axis technology: — focal point to be freely set and is especially impressive Size of the labeling field: between 120 x 120 mm and 330 x 330 mm.

Request for a quote

MITCHELL AND SON 3D PRINTING SERVICE

United Kingdom

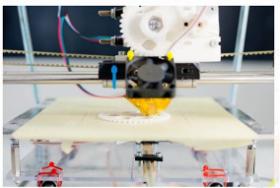

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. Mitchell and Son 3D Printing Service provides a totally bespoke 3D Printing Service for all sectors using a range of materials. Additive manufacturing uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. . It is defined as the process of joining materials to make objects from 3D model data, usually layer upon layer. Benefits of additive manufacturing (3D Printing Below are four major advantages that additive manufacturing can provide to help companies reduce cost, timing, and risk. ... 4 Major Advantages of Additive Manufacturing Reduced Tooling Costs. ... Quicker Speed to Market. ... Easily Test Complex Component Geometries. ... Better Component Quality.

Request for a quote

FORMEON

United Kingdom

Reverse engineering involves 3D scanning an existing object to understand its structure, function, and operation, often to replicate or enhance it. It typically starts with 3D scanning to capture precise data, which is then used to create detailed CAD models and reinstate the original design intent.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

3d objects - Import exportNumber of results

5 ProductsCountries

Company type