- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial ceramics

Results for

Industrial ceramics - Manufacturer Producer - Hungary

HungaryManufacturer/producer

Product recommendations

France

China

China

Austria

-

KEROX DENTAL LTD.

Hungary

-

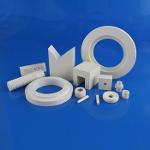

OFFICINA CERAMICA LTD

Hungary

-

BAKONY IPARI KERÁMIA KFT

Hungary

-

CERLUX IPARI KFT

Hungary

-

UNIKERAM MUSZAKI KERAMIA KFT

Hungary

A page for your business

Can you see this?

Your potential clients will too.

Join us now so you too can be visible on europages

Filters

Results for

Industrial ceramics - Manufacturer Producer - HungaryNumber of results

8 CompaniesCountries

Company type