- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

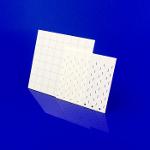

- ceramic substrate

Results for

Ceramic substrate - Manufacturer Producer - Germany

GermanyManufacturer/producer

Product recommendations

China

China

China

China

-

ÄTZTECHNIK HERZ GMBH & CO. KG

Germany

-

MICRO-HYBRID ELECTRONIC GMBH

Germany

-

HHI HUBERT HEUSNER INDUSTRIEVERTRETUNGEN UND HANDEL

Germany

-

MICRO SYSTEMS TECHNOLOGIES MANAGEMENT GMBH

Germany

-

MICRO SYSTEMS ENGINEERING GMBH

Germany

A page for your business

Can you see this?

Your potential clients will too.

Join us now so you too can be visible on europages

Filters

Results for

Ceramic substrate - Manufacturer Producer - GermanyNumber of results

6 CompaniesCountries

Company type