YILMAZ MACHINE - WE VALUE YOUR THOUGHTS

Turkey

Manufacturer/ Producer

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION KP 110 machine is designed and constructed for the pneumatically crimping and correct assembly of aluminum profiles. The machine is semiautomatic and the machining cycle of various units are manual controlled by user who always stays outside of the dangerous area. It is designed through the pneumatically crimping system Cast iron construction of the body that is strong and lasting Magnetic support of knives according to the shape and height of the profiles Reading of the positioning value via millime ter special scales Simultaneous stroke of crimping heads Double-acting stroke of bracing clamp apears from the table Support arms on the left and right of the machine The machine is equiped with the foot pedals for the operation control during the machining cycle Operator safety guard Operating stroke of knives : 10.5 mm Bracing clamp stroke: 80 mm Adjustable stroke of knives: from 30 mm to 60 mm STANDARD ACCESSORIES • 1x3 mm, 1x5 mm and 1x7 mm crimping knives

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION KP 120 machine is designed and constructed for the hydraulically crimping and correct assembly of aluminum profiles. The machine is semiautomatic and the machining cycle of various units are manual controlled by user who always stays outside of the dangerous area. It is designed through the pneumatically crimping system Steel construction of the machine table that is strong and lasting Practically adjustment of the knives according to the shape and height of the profiles Practically adjustment of the cylinder feed and profile stops by means of the millimetric ruler The machine is equipped with the pneumatic (for clamps ) and hydraulic (for crimping ) foot pedals for the operation control during the machining cycle Double-acting centering set-square returns to the home position under the table after crimping Powerful hydraulic pump with 2 x 5 tons capacity Protection plates made of Polyamide material to prevent being scratches on the profile surface

Request for a quote

YILMAZ MACHINE

Turkey

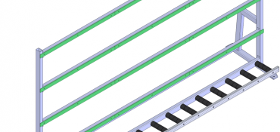

PRODUCT INFORMATION General Features: Used for carrying the completed window assembly By means of W200 mm of free wheel, windows can be moved easy In order to prevent the scratches and easy movement of the frames it is used plastic rollers Width (W) x Length (L) x Height (H) : 650 x 3000 x 1700 mm Loading capacity: 500 kg TECHNICAL SPECIFICATIONS

Request for a quote

YILMAZ MACHINE

Turkey

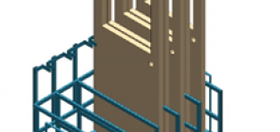

PRODUCT INFORMATION GENERAL FEATURES: Used for carrying and storing doors In order to prevent scratces the metal surfaces are coated with plastic based painting 4 pieces of free moving wheel, 2 of which have brakes 10 pcs. of sections available Width (W) x Length (L) x Height (H): 990 x 1527 1290 mm Distance between sections: 106 mm Length of holding bars: 990 mm Loading capacity: 500 kg TECHNICAL SPECIFICATIONS

Request for a quote

YILMAZ MACHINE

Turkey

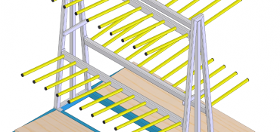

PRODUCT INFORMATION General Features: Used for carrying and storing vertical profiles 4 piece of free moving wheel, 2 of which have brakes • 2 x 10 section Plastic covered surfaces to prevent scratches on work pieces • Width (W) x Length (L) x Height (H) : 1440 x 1540 x 1800 mm Distance between sections: 113 mm • Length of holding bars: 500 mm Loading capacity : 600 kg TECHNICAL SPECIFICATIONS

Request for a quote

YILMAZ MACHINE

Turkey

VK 420 is designed for the precise V cutting and 90° end notching operations with minimal off cut size on aluminum and PVC profiles. Machine is constructed to minimize the off cut size Hydro-pneumatic V sawing head infinitely adjustable according to the profile Manual adjustable of back fence working in T slot mechanism Double hand safety operation External adjustment of hydro-pneumatic saw blade feeding 90 degree of notching operation (optional) STANDARD ACCESSORIES • 2 x T.C.T saw blades, Ø 420 mm • 2 x Horizontal pneumatic clamps • Service spanner • Air gun • Spray saw blade lubrication system

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION General Features: Used for carrying and storing completed window assembly 4 piece of free moving wheel, 2 of which have brakes • Loading Surfaces are covered with rubber to prevent scratches on work piece Width (W) x Length (L) x Height (H) : 1740x 1540 x 1950 mm Loading capacity : 500 kg TECHNICAL SPECIFICATIONS

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION General Features: • Used for carrying and storing completed window assembly • 4 piece of free moving wheel, 2 of which have brakes • • Loading Surfaces are covered with rubber to prevent scratches on work piece • Width (W) x Length (L) x Height (H) : 1740x 1540 x 1950 mm • Loading capacity : 500 kg TECHNICAL SPECIFICATIONS

Request for a quote

YILMAZ MACHINE

Turkey

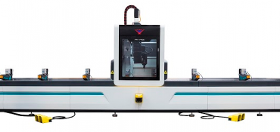

PRODUCT INFORMATION AIM 4310 is 3-axis CNC controlled machining center which is designed for the working of all kinds of aluminum & PVC profiles, light alloys in general and temporary operations of thin-walled steel profiles with special cutters. By means of the additional aggregate tool, various profiles can be machined with 4-axis movement. The machine can be used in tandem mode, a work method that allows to machine stop times to be reduced to a minimum as it allows workpiece change time (loading/unloading) to be run "while the machine is operating. The machine has automatic vise positioning feature (with CAMPROX software) and equipped with magazine unit holding 8 tool-units (second magazine unit optional) with the possibility of placing 2 aggregate tools and 1 milling saw to perform machining on the 5 sides of the pieces. Isolated cabinet reduces the noise of machine and provides safety of the operator. GENERAL FEATURES: • Designed for all kinds of drilling, grooving,...

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION AIM 4420 is a 4-axis servo-controlled machining center that is designed to perform drilling, grooving, notching, taping, sawmilling, etc. on all kinds of aluminum & PVC profiles, light alloys in general and thin-walled steel profiles. Efficient and economic processing on the three sides of the profiles is possible with this fully automatic machining center. General Features: • It is designed to make operations on three surfaces of the profiles such as a hole, slot, corner relieve, saw cutting, tapping, flow drilling, etc. • CNC automation system providing motion control at 4-axis • Linear type of magazine unit for 11 standard tools and Ø180 mm of the saw blade • Flow drilling and tapping feature by means of encoder spindle (optional) • Automatic clamp recognition and clamp positioning are available • CNC controlled spray tool lubrication system • Pneumatically working 4 pcs of clamps for gripping the workpiece

Request for a quoteManufacturer/ Producer

Taşdelen Mah. Atabey Cad. No:9

Çekmeköy

34788 Istanbul - Turkey

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

APD MAQMASTER

Spain

Economical workbench with 3 extendable arms and inverted T-leg.

Request for a quote

HELIOS

Romania

Performant 88 residential doors are characterized by a multitude of technological performances that ensure a high level of reliability, outstanding thermal insulation, excellent weatherproofing and good static properties. The greater thickness of the panel ensures both a higher level of insulation but a higher resistance to break-in attempts. You will always make the right decision by choosing the Performant 88 door. PVC 6-chamber profile with an 88 mm constructive depth Maximum size for doors with one leaf 1200x2400 mm Gaskets: 2+1 Wide range of glass or panels with a standard thickness of 52 mm Glass package rod: Aluminium or Warm Edge Increased security due to the closing system with bolts and hooks A wide range of construction options, doors with a single or multiple leaf, with skylights, decorative panels or even arched. Colours: white, wood textures, mate, metallic or bicolour colours.

Request for a quote

HELIOS

Romania

Performant 88 Premium offers you everything you need for a high quality residential door: exceptional design and chromatic variety due to aluminium plating, the best thermal insulation for this type of profiles, modern construction depth of 93.5 mm, more resistance at weather and burglary due to the 52 mm panel. PVC 6-chamber aluminium plated profile, with a constructive depth of 93,5 mm Maximum size for doors with one leaf 1100x2200 mm Gaskets: 2+1 Wide range of glass or panels with a standard thickness of 52 mm Glass package rod: Aluminium or Warm Edge Increased security due to the closing system with boltsand hooks. Possibility of installing automatic closing systems You can order these doors in a variety of constructive options: in one or more leaves, with skylights or side panels, with glass or decorative panels. Colours: white, wood textures, mate, metallic colours or bicolour (RAL range on the outside). Glass options: burglar, secure, variety of frosted and decorative glass.

Request for a quote

HELIOS

Romania

The Elegant 76 door perfectly combines the aesthetic benefits of aluminium and the functionalities of PVC, such as optimal insulation, high stability and impeccable working. Your customization options are practically limitless, the aluminium cladding gives you the opportunity to play with both the colour of the profile as well as the colours of the panel or the type of glass. PVC 5-chamber aluminium cladded profile with 81.5 mm constructive depth Maximum size for doors with one leaf 1100 x 2500 mm Gaskets: 2 + 1 Wide range of glass or panels up to a maximum thickness of 48 mm Glass package rod: aluminium or warm edge Possibility of installing automated access systems Increased security due to the locking system with bolts and hooks You can order these doors in a variety of options: with one or more leaves, with skylights or side panels, with glass or decorative panels. Colours: white, wood textures, matte, metallic colours or bicolour (RAL range on the outside).

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free