- europages

- >

- Sensors

- >

- TWK-ELEKTRONIK GMBH

- >

- products

TWK-ELEKTRONIK GMBH

Germany

Manufacturer/ Producer

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position ring, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a displacement signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to an analogue measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. Electrical connection is implemented via a circular connector. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

This involves a play-free electronic switching cam encoder (abbreviated to: NOCI) with a maximum of four galvanically separated1) SIL2 switching outputs that can be set by the customer, and which are activated or deactivated depending on the respective position of the drive shaft. A parameterisable multiturn absolute encoder with incremental interface as well as the four switching outputs are integrated in the compact housing. The switching outputs can be preset. A special shaft design appropriate to the play-compensating measurement gear ZRS is available. The supply voltage, incremental signal and switching contacts are each galvanically separated from one another

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

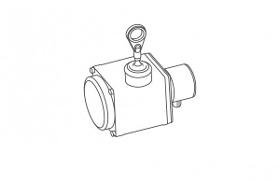

Please note that this product is an accessory. In the "Products" section you will find the corresponding encoders that you can order for your selected article. The linear movement of a flexible steel cable, which can have a length of up to 30 m, is converted into an rotary movement with the aid of a measuring drum. The measuring drum is connected to the shaft of an encoder. In this way a change in displacement of the measuring cable causes the shaft of the encoder to rotate by a directly proportional amount which can be recorded. The restoring force of the spring drive holds the measuring cable tight at all times and prevents any sagging which would otherwise induce an error. The measuring drum moves axially on a spindle ensuring that the cable is wound up precisely and reproducibly wrap for wrap in the helical groove of the drum. The nozzle, through which the cable enters the drum, is protected with a brush and a bellow to prevent water or dust entering the drum.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The linear movement of a flexible steel cable up to 2m long is converted into a rotary movement by a measuring drum. A return spring prevents the steel cable from sagging. The measuring drum is connected to a pulse generator, which generates two pulses every 0.1 mm offset by 90°. The measuring drum winds the steel cable in a single layer so that the resolution is independent of the position. The rope entry is protected against dirt by brushes.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

This involves a play-free electronic switching cam encoder (abbreviated to: NOCE) with a maximum of four galvanically separated switching outputs, which can be set by the customer and which are activated or deactivated depending on the relevant position of the drive shaft. A parameterisable multiturn absolute encoder with SSI interface plus the switching cam encoder printed circuit board with separate controller are integrated into the compact housing. The SSI interface can be preset, the code direction can be set and the switching outputs can be preset.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Please note that this product is an accessory. In the "Products" section you will find the corresponding encoders that you can order for your selected article. The linear movement of a flexible steel cable, which can have a length of up to 40 m, is converted into an rotary movement with the aid of a measuring drum. The measuring drum is connected to the shaft of an encoder. In this way a change in displacement of the measuring cable causes the shaft of the encoder to rotate by a directly proportional amount which can be recorded. The restoring force of the spring drive holds the measuring cable tight at all times and prevents any sagging which would otherwise induce an error. The measuring drum moves axially on a spindle ensuring that the cable is wound up precisely and reproducibly wrap for wrap in the helical groove of the drum. The nozzle, through which the cable enters the drum, is protected with a brush and a bellow to prevent water or dust entering the drum.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Cylindrical case in anodised aluminium - Shaft in stainlesssteel - Conductive plastic resistance elements - Precious-metal wipers - Axial connector or radial leads - Ball joints atshaft end and / or case at option - spring return (gauge) at option.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Please note that this product is an accessory. In the "Products" section you will find the corresponding encoders that you can order for your selected article.The linear movement of a flexible steel cable, which can have a length of up to 5 m, is converted into an rotary movement with the aid of a measuring drum. The measuring drum is connected to the shaft of an encoder. In this way a change in displacement of the measuring cable causes the shaft of the encoder to rotate by a directly proportional amount which can be recorded. The restoring force of the spring drive holds the measuring cable tight at all times and prevents any sagging which would otherwise induce an error. The cable is wound up precisely and reproducibly wrap for wrap in the helical groove of the drum. The nozzle, through which the cable enters the drum, is protected with a brush and a bellow to prevent water or dust entering the drum. Two roller units at the cable entry allow for up to 20° <) deflection of the cable.

Request for a quoteManufacturer/ Producer

Bismarckstraße 108

40210 Düsseldorf - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

RIEGLER & CO.KG

Germany

The cylinders described here are pneumatic drive units mainly for linear movement. The piston rods or the magnetic traction transfer the movement of the piston to the components to be moved. We offer round, short-stroke, compact, profiled barrel cylinders and piston rod-free drives. In addition you will find here a whole range of sensors, fastening parts and accessories. Our piston rod cylinders are fabricated according to various ISO standards and are available in single-acting or double-acting design. They are suitable for filtered, unoiled or oiled compressed air.

Request for a quote

PRAXAS B.V.

Netherlands

The Logtag Logtag TRED30-16R Temperature Logger with external sensor is specifically for monitoring temperature during transport and storage. The data logger has a capacity of up to 15,900 measurements and a measuring range of -40°C to +99°C from an external sensor.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turn-milling compound machining flange

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel processing in Turning ,Milling.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free