SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Manufacturer/ Producer

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The EcoResinator is particularly suited to full the specic demands that are made on the technology employed for the glue-blending system used to manufacture MDF. Siempelkamp has equipped the EcoResinator with Schlick two-component nozzles. The second component that is used with the glue is steam. The size of the glue droplets is set with the help of the steam pressure and quantity. The corresponding parameters required for achieving the best possible application of glue based on the breboard's density are stored in the program. The optimised gluing methods may either be used to improve strength with the same amounts of wood and glue o and bres while preserving the same strength. The EcoResinator can potentially save up to 15% of glue over classic b recommended for all MDF plants. The EcoResinator also oers benets when existing plants are modied at a later point in time. The glue-blending sy within 24 hours.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Short-cycle presses are for rening the nishes on boards made from woodbased materials. Accordingly sanded particleboards and MDF / HDF with smooth nely pored surfaces are particularly suitable. Features, function A hot press is used to permanently apply resin-soaked paper to the surfaces of boards made from wood-based mate pores and in this way is responsible for adhesion. It also creates a surface that is resistant to a variety of environment for the colourless resin and for the decorative layer.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

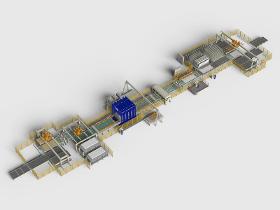

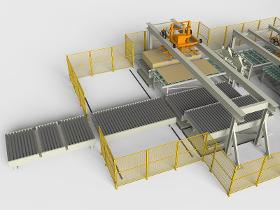

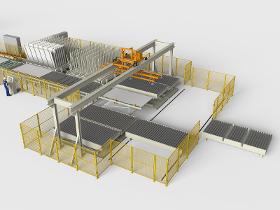

The boards to be coated are fed to the raw-board-handling section where they are separated to allow their surfaces to be cleaned. Features, function A forklift truck is used to place the board stacks on to a roller table from where roller conveyors or horizontal transfer carriages equipped with roller conveyors transport them to one of the two separating station's places. A suction carriage removes the top board from the stack and places it on a conveyor that takes it to the surface-cleaning machine. Advantages The two redundant stacking places allow the short-cycle press to be supplied without interruption. They make it possible to feed new stacks of boards without the need to shut the machine down

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Papers and carrier boards are combined in the batch laying section. In the simplest of cases, a batch that is ready for pressing consists of a sheet of decorative paper as the base layer, a carrier board and a sheet of decorative paper as the top layer. It may in certain circumstances be necessary to use of several types of paper. Features, function Papers soaked in resin are supplied to the plant in sheets lying on pallets. A suction bar separates the papers from the stack and pulls them on to a laying conveyor. A suction carriage delivers the board made from wood-based material. The laying conveyor conveys the batch from laying station to laying station / conveys the assembled batch to the facility core. The batch is statically charged in order to secure the papers on the carrier board for continued transport. Advantages The individual layout of the batch layer is based on coordinated standard modules.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The hydraulic hot presses have been dimensioned in such a way that they are able to exert and evenly distribute a specic pressure of at least 400 N/cm² on the product. Features, function The loader takes up the pressing batch at the transfer station. The previous nished board is removed from the press and the new press batch is transferred into it. The subsequent pressing time depends on the resin's reactivity, the selected pressure and the set temperature Advantages The press uses a multi-cylinder design that, with the pliant hot platens used, permits the specic pressure on the product to be set very precisely. Path-controlled press operation permits a cylinder movement that is technologically optimised with the loader’s and unloader’s cycle times tuned accordingly.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The boards are trimmed, cleaned, checked and (if necessary) cooled in the nishing line. Features, function Any excess material caused by the decorative paper being larger than the carrier board is removed from edges on the nished boards in the edgetrimming unit. Rotating brushes then remove any residues that are clinging to the surface. A member of sta will visually assess the quality of the coated board on both sides at the inspection station. The boa station so that it can be inspected from the bottom. The board is then placed in the stack appropriate for its quality Advantages The modular design allows basic modules and optional modules to

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

This is where the nished boards are sorted by quality and stacked for transport. Features, function The nished boards are transferred from the nishing line, centred, taken up by a suction carriage and placed in dierent stacks depending on the quality assigned in the nishing line. A horizontal transfer carriage picks the stack up and transfers it to a transfer stack. It can be removed by a forklift truck from here. Advantages The options also permit a top and bottom protection board to be put in place without this having an impact on plant performance.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Büttner's fash-tube dryers are most versatile and extremely ecient. The dryer systems are used for drying material having high levels of surface moisture or a specic surface area. They are, for example, used to pre-dry wood akes before they are conveyed into drum dryers. Flash tube dryers are also used as the principal dryers for drying bres to be used in MDF production. For many years Büttner's ash tube dryers have been in operation successfully in many dierent industrial sectors all over the world Features Water evaporation of up to more than 70 t/h per unit depending on the product Drying within just a few seconds, the material is then already mechanically separated and conveyed to the downstream drum dryer. Flash tube dryers may be heated in many dierent ways, for example: Flue gas from grate ring Büttner gas line burners Hot gas from gas turbines or gas motors Indirectly by heat exchangers for steam or thermal oil Any combination of the heating methods mentioned above

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

MDF forming lines consist of machines for forming and monitoring the bre mat. Additional devices for quality monitoring complete the function. The plant modules can be adjusted to the respective requirements thus preparing the mat optimally for its compaction in a ContiRoll®. The equipment is designed to produce board thicknesses between 1.5 and 40 mm without any problem. The forming belt conveyor is a modular design as well tuned to plant output and feasible board formats. Features Forming belt with pneumatic tensioning station as well as electric drive station and integrated automatic reject m Integrated belt scale for controlling the mat former output to ensure consistent product quality Mat moisture meter Automatic edge trimming system ex prepress Monitoring equipment to prevent steel belt damage peak detectors metal detector

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The mat former for MDF production inuences signicantly the output and the quality of the nal product. Its components ensure the material ow from the metering bin inlet, the bin discharge front onto the forming heads underneath up to the levelled bre mat on the forming line. MDF usually requires a homogeneous one-layer mat to be formed on the forming belt. To realise this we use a mechanical forming head (Siempelkamp StarFormer). Features, function Controlled material feed into the bre bin Chute equipped with bre decelerators to reduce the dropping speed of the bres Bin casing providing a buer time of up to 5 minutes Controlled bin bottom belt Discharge front with oset disc rollers Flow-optimised chute Mechanical StarFormer incl. level and angle adjustment

Request for a quoteManufacturer/ Producer

Siempelkampstr. 75

47803 Krefeld - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in mechanical shaft.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Engines for combined heat and power plants are operated with different fuels, including hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels. In an exhaust gas heat exchanger, the hot exhaust gas from the CHP engines or CHP gas turbines is cooled, in the process heating water, a water-glycol mixture or thermal oil. This thermal energy can be used in a local or district heating system or for other industrial purposes.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Silencers/Mufflers; diesel and gas engine exhaust noise is designed based on required target noise levels and current pressure drop. In addition to the standard silencers for stationary engines, special silencers are designed and manufactured according to customer specifications. In addition to reducing exhaust noise, extremely compact designs are made with the available space in mind.

Request for a quote

STEEC

France

Wire spark erosion, laser micro-cutting, micro-milling and micro-drilling STEEC is also involved, both as a subcontractor to numerous SMEs and agencies in the metallurgy and mechanical engineering sectors which very often engage in subcontracting activities themselves. STEEC enables these players to respond to invitations to tender that involve meeting precision micro-machining requirements for which they are not equipped. The wide variety of precision micro-machining operations which STEEC offers is highly beneficial to these SMEs and agencies, which are able to offer a comprehensive service in micro spark erosion, laser micro-cutting, micro-drilling and milling.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free