SERVOLIFT GMBH

Germany

Manufacturer/ Producer

SERVOLIFT GMBH

Germany

The SERVOLIFT cleaning chamber system is equipped with a fully automated, adjustable height interior and exterior cleaning system which focuses on simple handling and energy efficiency. A circulating air system ensures optimal drying and also cooling of various container sizes and geometries. Accessories to the container are integrated in a support frame and cleaned without spraying ‘shadows’. The chamber is designed as a front-loader, conveyor chamber, double chamber, installed in a pit or mezzanine flevel or on floor construction in accordance with the required performance, installation situation and clean- unclean environment. In addition to technical considerations, SERVOLIFT paid special attention to optimizing consumption in order to keep operating costs as low as possible. A+++ cleaning Technical description Temperatures, pressures, volume flows, quality of the wash medium and drying/cooling air are scanned. All operating statuses are presented on the terminal, the...

Request for a quote

SERVOLIFT GMBH

Germany

Before solid products, agglomerates or clumps can be sieved or calibrated, these must be broken up or crushed. Suitable materials are available to break up the product in drums with the right SERVOLIFT systems. Pinpoint pressure Technical description Sequence: Drum crusher: Products solidly in drums are broken up in drum crushers in order to discharge them. Primary crusher: Large fragments are crushed with the primary crusher into fist-sized lumps. Clump crusher: Larger clumps are broken up by the clump crusher for the sieve mill to a workable size. The machines can be combined with one another, or be used on their own. A protective device is adapted to the relevant use case.

Request for a quote

SERVOLIFT GMBH

Germany

The broad applications spectrum of SERVOLIFT milling and sieving equipment leads to flexible and user-friendly solutions in combination with handling systems. The areas of application stretch from controlled sieving in order to remove contamination from raw materials to fractionation, calibration to deagglomeration. Sieve mills, vibration sieve machines or inline sieve equipment in combination with mobile or stationary lifting systems provide a flexible, compact and easy-to-clean system. Size as needed Technical description Stainless steel or cGMP/FDA compliant designs Use as sieve mills (cone mills), hammer mills, oscillating sieve mills Various throughput depending upon the product and particle size Lifting height can be customized Broad control designs, from simple microcontrollers with digital displays to PLC controls Explosion-protected designs in adherence to Atex Zone 1/21 and 2/22.

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT laboratory blenders are ideal for producing small batches under production conditions. This is possible through the container’s geometry, which is adapted from the large production blender. The knowledge gained from blending tests creates a reliable basis for later manufacturing. Parameters such as RPM and time can therefore be varied. Small size - large effect Technical description Compact blender, ideal for product and process development Operate on a control or touch panel Design and geometric relationships correspond to the large production blenders Also available as test and loan unit

Request for a quote

SERVOLIFT GMBH

Germany

These blenders are especially well-suited to the area of pilot facilities, small batches, production as well as test. Its flexibility results from the various designs, such as mobile or stationary, as well as the use of exchangeable blending containers, such as containers, round tanks, double cones and V-containers. It can be expanded through installations and conversions of choppers, spray systems and NIR systems. More than just blending Technical description Load capacity: 150 kg Protective hood, Macrolon plate in an enclosed stainless steel frame Non product contact material AISI 316L / AISI 304, Ra < 1.4 μm Product contact material AISI 316L, Ra < 0.8 μm Blender individually exchangeable: Container, drum, double cone, special containers Further optional functions: Spraying system, NIR, active tools Blending drive: frequency-controlled worm drive brake motor, blending RPM: 5-20, adjustable Blending time 0-99 min., adjustable Control: PLC, Siemens S7 operation, touch...

Request for a quote

SERVOLIFT GMBH

Germany

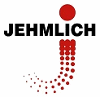

SERVOLIFT’s drum blender is designed for the demands of the pharmaceutical and chemical industries. Equipped with easy-to-use equipment, optimal ergonomics, converted to a space-saving and compact machine housing. The blender offers the ability to take up drums of varying sizes. The drum blender can be ideally connected to previous or follow-on processes, to refill or sieve into underneath placed containers, for easy attachment of drums either manually or hydraulically, to blend various containers with fitting clamp or take-up systems. Blending and Handling Technical description Stainless steel or cGMP-compliant design Can lift all customary drums as well as special drums Free-standing or floor- or ceiling-mounted design Loading using trolleys, hand lifters up to fully automatic roller conveyor feeds and unloading Various container clamping systems, from manual up to fully automatic designs Safety housing depending on where set up, and processes Standard tipping setting on the...

Request for a quote

SERVOLIFT GMBH

Germany

The bin blender is a special form of free-fall blender. Bin blenders are used wherever the volume of usually available containers are not sufficient for the batch, or the given process requires a fixed clamped blending container. The design of the bin blender can be customized to customer specifications. Whatever the bin shape - square, rectangular, round with a cone, double cone - symmetrical or asymmetrical, V-container - all these bin blenders from SERVOLIFT can be extended in order to perform the installation and extension functions as with typical container blenders. This includes an optional and useful WIP cleaning to clean the blender chamber. Blend in customer-specific containers Technical description Stainless steel or cGMP-compliant design Free-standing or floor- or ceiling-mounted design Loading using docked containers, vacuum transport systems, gravimetric feeding and discharging. Dosing systems for discharging Safety housing depending on where set up, and...

Request for a quote

SERVOLIFT GMBH

Germany

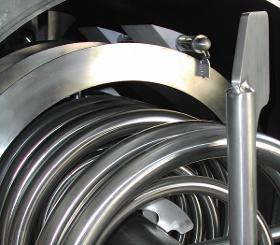

The SERVOLIFT cleaning station ensures optimal internal container cleaning in a fully automated process. This is based on a 4x washing program, which provides reproducible wash cycles combined with user- and recipe management. Suitable wash programs are defined which are adapted to individual contamination and container geometry. Wheels and an ergonomic handle make the system movable and easy to manoeuver. The integrated printer documents the individually executed steps of the washing cycle. Outside cleaning is done manually, and completes the entire semi-automatic washing process. The system can be extended to a validation-capable, separate drying station in order to reduce production container downtimes. As an alternative, one can integrate a drying unit into the semi-automatic wash station. Flexible and easy cleaning Technical description PLC control, adhering to GAMP 5 guidelines with password and recipe management up to CFR 21 part 11 implementation Cleaning cover with...

Request for a quote

SERVOLIFT GMBH

Germany

The SERVOLIFT drying station completes the cleaning steps in the SERVOLIFT semi-automatic wash station. The still-damp containers are placed in the drying station, which is placed in a separate drying area. The work is done nearby in the same room. The system can be used as a compact unit separated in an equipment area. The drying station takes up very little space. The complete system ensures a successful drying process in the shortest time with very low energy use. Fast and efficient Technical description Drying using air circulation with approximately 60% fresh air input Heat exchanger, electric, approx. 9KW Drying temperature up to 80° C Control - microcontroller with digital display Adapter for drums Vertical or horizontal construction

Request for a quote

SERVOLIFT GMBH

Germany

The number of HPAPI (High Potency Active Pharmaceutical Ingredient) has been continuously increasing over the past view years. At the same time, the manufacturing industry wants more flexibility in production to respond faster and more accurately to needs and changing demand. The complete IBC cleaning and drying solution for substances with high hazard classification up to OEB 5 for pharmaceutical industries is at the end of all process steps in pharmaceutical solids production and meets this requirement including full validation. Validated interior cleaning adapted to space and product Technical description suitable for high containment containment Valve system with Split Butterfly Valves single-stage washing principle, no water circulation to avoid cross-contamination hydrokinetic head for cleaning (container) inner surfaces hydrokinetic head for cleaning bottom valves recipe controlled system with automatic controls, sampling, batch reporting and security access drying with...

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

KASAG SWISS AG

Switzerland

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

We can offer the vertical and horizontal Meat Drum Machine we produce with the following features: Hourly product processing capacity from 300 to 1,000 kg refrigerated Spoon Stirring Moving product mixing and product discharge With these features, our machines provide the product, Marinating / Marinating It tenderizes the meat. mixing it up It's like resting for 36 hours It speeds up the production process Bottled/Ready to cook Vacuum It allows transportation without breaking the cold chain. Our product vacuum drum is designed to massage and soften products such as ham, shoulder, ribeye, sirloin etc. under vacuum. With its cylindrical body and herringbone internal structure, it ensures that the product is homogenized evenly. With its wide adjustment range automation system according to demand, it ensures increased finished product and the best binding of proteins to the meat.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

Meat Drum Meat Transfer Troughs lifting device is designed for food industry operations and is used for lifting and tilting manipulation carts. The trolley is designed to meet customers' requirements and the loading process of largely processed and unprocessed products. The part of a trolley filled with material is inserted into the tilting fork, which is a groove. Its advantage is that it is adjustable and can be produced according to customer needs. The fork provides easy and quick bending of the material into a machine where it is subsequently processed. It represents important additional equipment, the use and commissioning of which leads to acceleration and significant simplification of the entire production process.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

General description Our company has designed and manufactured the meat loading elevator machine by ensuring the following: – highest level of safety in operation, cleaning and maintenance; – the highest hygiene standards thanks to the correct material selection and the refined design of the elevator parts in contact with food in order to achieve easy cleaning and disassembly; – maximum efficiency with horizontal angle loading system; – hardness and stability of parts – lowest noise level - very useful Construction features The mixer consists of 304 stainless material and is resistant to rust and corrosion.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free