ROTA MACHINERY MANUFACTURING CONTRACTING - Manufacturer and service provider of painting and pretreatment lines and machining

Turkey

Manufacturer/ Producer

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

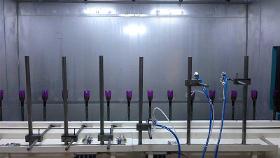

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling. Recycling is done with the cyclones in our powder coating booths with cyclone. It is preferred because it allows easy and fast color change. The powder particles which are not used passes through the cyclone unit before the filter unit. While the particles go down through cyclones with centrifugal effect, the particle that cannot be reused is sent to the filter unit and filtered there. The parts which are suitable for recycling are recycled to the system for reuse. Multi and mono type cyclone units are used in our booths. Both types offer efficiency with recycling systems, practicality with easy color changing. In filter cabins, it is necessary to change

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Stainless steel operations need a well-experienced team and new technologies to process. We have been operating precious metals for more than 20 years.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with water curtain, the air is sucked through the water curtain by exhaust fans while the unused wet paint is held by water. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Brass operations need a well-experienced team and new technologies to process. We have been operating precious metals for more than 20 years.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling. In our powder paint booths with filter, the air is sucked through the filters while the unused powder particles are held by filters. The filters are automatically and periodically pumped air in reverse direction to direct the powder paint that held by filters to the sieve tanks which is under the cabinet for reusing. As a result of this process, the unused powder paint is recycled. Polyester-Teflon and Sinter-Lamellar type filters are used in our booths. Polyester-Teflon filters are preferred due to their low cost and Sinter-Lamellar filters are preferred due to their long filter life. Both types offer efficiency with recycling systems, economical solution

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"Custom Design Flange Manufacturing Custom design and standard flanges manufacturing"

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our Infrared ovens can be produced as conveyor belt tunnel or internal return (U) type. Our ovens have andirect heating system with radiation heat transfer. They are used due to the cure flat shaped parts after wet or powder coating paint applications. They are preferred because they can cure the paint three times faster than the convectional type ovens. They can be produced with natural gas or lamp type infrareds. The inner surfaces of our ovens’ panels are produced with a galvanizedor stainless steel sheets and the outer surfaces are produced with galvanized sheet steel coated with electrostatic powder paint. Considering the application temperature, the required thicknesses determined and rock wool or glass wool is used for insulation.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our box type ovens have the indirect heating thermo-block system with convection heat transfer. It can be manufactured according to power supply sources like electricity, gas or liquid fuel. The inner surfaces of our ovens’ panels are produced with galvanized sheet and the outer surfaces are produced with galvanized sheet steel coated with electrostatic powder paint. Considering the application temperature, the required thickness (usually 160mm) is determined and only rock wool is used for insulation. For paint applications up to 220 °C, for special purposes up to 400 °C ovens can be produced by our company. The doors of our box type furnaces can be produced as double-sided, top opening or as guillotine door according to needs.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

In the spraying pre-treatment method, applying chemicals with a certain pressure on the parts creates big positive differences on paint quality and life span. By cleaning and coating the surface of the part before painting, the paint will retain its first-day quality with out any degradation for long years by strong adhesive forces. Our spray tunnels, with the help of automation systems, allow you to be able to produce automatically and continuously with out any touch. Tunnel type spray surface cleaning lines consist of parts like spray nozzles, heat exchangers, dosing pumps and ventilating systems. In our spray lines, the AISI 304 – AISI 316 stainless sheets of steel and polypropylene are used. According to needs of our esteemed customers, horizontal belt type conveyor, compact type, and rotary table type automatic plc controlled washing machines can be produced by us. Some chemicals which are used for surface cleaning must be applied hot. Due to this situation

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The dipping system which is one of the other methods is produced with a robot or crane controlled. The systems are equipped with the most efficient heating, ventilating and PLC control equipment. In our dipping lines manufacturing, AISI 304- AISI 316 stainless sheets of steel and polypropylene are used. The system should be selected according to the shape of the part, the area to be used and the corrosion resistance. Some chemicals which are used for surface cleaning must be applied hot. Due to this situation, our company produces cold dipping lines as well as natural gas heated, electric heated, liquid fuel heated and water heated dipping pre-treatment lines according to the energy source that is planning to be used.

Request for a quoteManufacturer/ Producer

Deri Organize Sanayi Bol. Tabakhane Cad.

Yb15 tuzla

34956 Istanbul - Turkey