RINGFEDER POWER TRANSMISSION GMBH

Germany

Manufacturer/ Producer

RINGFEDER POWER TRANSMISSION GMBH

Germany

The slit versions are useful in applications requiring the bridging of bigger tolerances and/or higher torques. Stacking of the elements is not recommended. Characteristics Customized application – by varying the number of Locking Elements, size and quantity of clamping screws, the connection can be adapted to fit most applications concerning surface pressures, materials, hub/shaft dimensions and available mounting space. Transmission of high loads – to increase the transmissible torque and axial forces up to 4 Locking Elements can be used in series. Maximum reliability – no matter whether the connection is subjected to static, pulsating, dynamic or intermittent loads. Simple manufacture – shaft and hub are designed without keyway. Apart from this, relatively large tolerances are admissible. Easy adjustability – Locking Elements work without positive connection. So they can be adjusted at any place to any position by following the simple installation and removal...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Simplified manufacture – only plain shaft and bore diameters with easily achieved surface finish and tolerances are required. Easy adjustability - Easy mounting - Easy removal - Low susceptibility to contamination - Highest reliability This product is available in the following configurations: SDA, SDB, SDC and SDD. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Simplified manufacture – only plain shaft and bore diameters with easily achieved surface finish and tolerances are required. Heavy duty series for high torque and bending moment. Easy adjustability - Easy mounting - Easy removal - Low susceptibility to contamination - Highest reliability This product is available in the following configurations: SDA, SDB, SDC and SDD. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Reduced dimensions with lower transmission values – especially for applications with restricted space. This light duty external locking device is the first in the Shrink Disc range and is useful for low to medium torque requirements. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine surface finishes, they also need...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Reduced dimensions with lower transmission values – especially for applications with restricted space. As a split version, the SR series is able to offer greater mounting versatility on symmetrical hub designs or can also be used as half shrink discs for lower torque applications. Half shrink discs With half shrink discs HT/HC only 50% of stated T is transmitted. Type HT (Threaded holes in thrust ring) Type HC (Clearance holes in thrust ring) Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

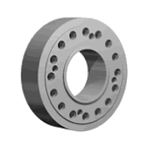

Standard series – this range is the most popular, being used in most applications. This new design of Shrink Disc is made from high alloy forged rings and is practically indestructible. Replacing the smaller 4071 design, these units are available from 14mm to 195mm bore. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Stainless steel series – for applications where corrosion resistance and high transmissible torque is required. This new design of Shrink Disc is made from stainless steel forged rings and uses high strength stainless steel screws. These units are available from 14mm to 195mm bore. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Shaft Couplings RfN 5071 Standard series – this range is the most popular, being used in most applications. Characteristics Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine surface finishes, they also need considerable effort with mounting and removal. The Shrink Disc connection has none of these disadvantages and is better than any of...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

RINGFEDER® Flange Couplings are the better alternative to press fits. Neither additional components such as keyways or wedges, nor a warming of the outer section and cooling of the inner section are required. The flange coupling is simply pushed onto the shaft and fastened so it is frictionally engaged by tightening the screws in the shrink disc. They transfer torque and bending moments as well as axial and radial forces. Advantages Strong connection with high torque capacity Easy assembly and disassembly Backlash-free shaft hub connection High level of true running accuracy Applications Mining companies Plant manufacturers Gearbox manufacturers Designs Version A Shrink Discs with hexagon head screws HM = Centering outside HF = Centering inside Version B Shrink Discs with hexagon socket head cap screws HM = Centering outside HF = Centering inside Explanations to tables Basic dimensions when screws are not tightened d w1 = Solid shaft diameter d w2 = Solid shaft diameter A =...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

RINGFEDER® Friction Springs consist of separate inner and outer mating tapered rings which stack together to form a column according to the customer’s wish. These units are repeatedly loaded 100% before delivery. Hereby the absolute functionality is ensured. Features of RINGFEDER ® Friction Springs RINGFEDER ® Friction Springs are employed in the engineering sector when high kinetic energies must be absorbed or when springs of relatively compact dimensions are required for high forces. RINGFEDER ® Friction Springs have multitude features in opposite to other damping systems: High spring work combined with low weight and volume: As RINGFEDER ® Friction Springs completely utilise the material of which they are made only a minimum of dimensions and weight are required. The decisive parameter here is therefore the spring work. High Damping Potential: The damping of RINGFEDER ® Friction Springs is standard with 66% wherewith the energy will be soon absorbed and resonances complete...

Request for a quoteManufacturer/ Producer

Werner-Heisenberg-Strasse 18

64823 Groß-Umstadt - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free