PEEKCHINA CO., LTD. - Engineering plastic PEEK profiles & parts manufacturer over 15 years.

China

Manufacturer/ Producer

PEEKCHINA CO., LTD.

China

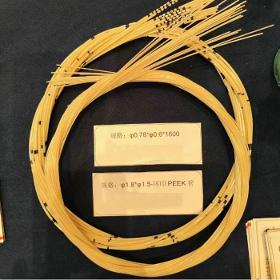

What is PEEK Catheter Tubing? Polyether ether-ketone (PEEK) is a thermoplastic polymer that can be extruded into catheter tubing with desirable properties such as high tensile strength, buckling resistance, good pushability and radiopacity. Why would you choose PEEK medical Tubing? Unlike polyimide, PEEK is melt processable and can be extruded into small diameter tubes for vascular catheters and larger diameter, thin wall tubes for non-vascular applications, such as Natural Orifice Transluminal Endoscopic Surgery (NOTES) devices. What medical devices or procedures is PEEK commonly used in? PEEK vascular catheters provide strong and flexible, small diameter tubing. Non-vascular applications such as endoscopic and laparoscopic procedures often demand larger diameter, thinner wall PEEK tubes.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK material performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK material performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK ARKPEEK-GF30: 30% glass fiber + 70% PEEK ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite

Request for a quote

PEEKCHINA CO., LTD.

China

ARKPEEK (PEEKCHINA) has developed high-purity, corrosion-resistant, low-elution PEEK high-performance plastic parts, which have been widely used in analytical chromatography instruments, preparative and semi-preparative chromatography instruments, protein purification equipment, IVD equipment, sample pretreatment equipment, pharmaceuticals and the environment. monitoring equipment and other related equipment.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK materials offer outstanding performance in extreme conditions, making these materials some of the best performing thermoplastics in the world. They offer strength, stiffness, long-term fatigue, and other properties that set them apart from other materials. Extraordinary temperature-, chemical-, and electrical temperature-resistance help PEEK materials endure in harsh conditions. Additionally, they have excellent high-temperature performance, with glass transition temperatures ranging between 289°F – 324°F and melting temperatures between 649°F – 729°F. PEEK materials also offer very good resistance to chemicals like dilute acid, dilute alkalis, oils and greases, aliphatic hydrocarbons, aromatic hydrocarbons, and halogenated hydrocarbons

Request for a quote

PEEKCHINA CO., LTD.

China

At the most important trade fair for industrial textiles and yarns, Techtextil 2019 in Frankfurt a. Main, presented the new product range of fluorinated polymers as well as the newly developed product range with the high-temperature polymer PEEK. The new product range of PEEK monofilaments includes diameters of 70 - 500 µm. The product range is produced on a newly constructed high-temperature spinning line. The new line allows the production of monofilaments with different shrinkage levels as well as the use of spinning dyes. The high service temperature in continuous use of 250°C is one of the outstanding properties of PEEK. In addition, PEEK monofilaments have good chemical resistance and are resistant to gamma radiation. The inherent flame retardancy is another outstanding property of PEEK. Due to their chemical and physical properties, the high-quality PEEK monofilaments are suitable for use with special screen and filter fabrics. Fabrics made of PEEK monofilaments ar

Request for a quote

PEEKCHINA CO., LTD.

China

100% unfilled PEEK natural PEEK(Polyetheretherketone)is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good mechanical properties and chemical resistance, abrasion resistance, and hydrolysis resistance properties etc.; it has a light proportion and self-lubricating properties.Mechanical and automotive engineering, nuclear and vacuum technology, transport and conveyor technology, textile, packaging and paper processing machinery, electronic and precision engineering, food processing. Key Features Temperature: -40°C up to +260°C. Creep resistant and excellent resistance to high energy radiation. Hydrolysis resistant, even against super-heated steam. Extremely strong and wear resistant plastic. Noise dampening. Highly machinable. MACHINING PEEK

Request for a quote

PEEKCHINA CO., LTD.

China

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. Composite material with PEEK matrix for parts with high structural characteristics Carbon PEEK is a composite material reinforced with carbon fiber, with extraordinary characteristics in terms of mechanical, thermal and chemical resistance. The addition of carbon fiber makes the material even more resistant from a mechanical point of view and allows you to go further in the Metal Replacement process even in the most extreme industrial sectors. Carbon PEEK finds application in a wide range of industrial sectors. It is used in very specific areas where a further increase in mechanical performance is required for out-of-the-ordinary performance.

Request for a quote

PEEKCHINA CO., LTD.

China

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature onditions. This is a special 30% glass filled PEEK modification that PEEKChina manufactures under the name PEEK GF30 natural. In comparison to unfilled PEEK, this glass fibre reinforced material exhibits increased mechanical strength and high rigidity. Furthermore, improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions. As glass fibres tend in some cases to have a marked abrasive effect on mating surfaces.

Request for a quote

PEEKCHINA CO., LTD.

China

ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite High performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical strength and high dimensional stability. The long term service temperature range of PEEK Rod is from -30°C to 250°C and has a short term maximum service temperature of 310°C. This compression moulded material is a PEEK polymer modified with 10% each of carbon fibre, graphite and PTFE for improved sliding and wear properties. Product characteristics including excellent sliding and abrasion resistance, high mechanical strength and high dimensional stability.

Request for a quoteManufacturer/ Producer

E801, Xintai Building, Taizhou

31800 Zhejiang - China