PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Manufacturer/ Producer

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Impact Hammer Mill, series PHPH ''Grizzly®'' was developed for the economical size reduction of residual- and waste wood of any kind. Not only pre-broken waste wood but also non precut, long recycling wood can be introduced into the mill. The machine distinguishes itself by high throughput rates at low specific energy consumption, low operating costs as well as robust and durable design. Any wood prepared with the „Grizzly®“ is used as a high quality and uniform raw material for material and thermal recovery. Characteristics, Function Material is fed horizontally from the front Size reduction is performed by impact and breaking combs and breaking ledges arranged behind the rotor Collection device for larger foreign objects which can be hydraulically opened for emptying Robust, wear-resistant and multi-split housing which can be easily opened via a hydraulic system Machine parts in the size reduction area made from wear-resistant and durable materials Oscillating hammers...

Request for a quote-20Bild0358f5d1f62a4718.82_4d26c671.jpg)

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

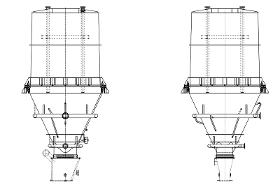

Correctly processed residual wood and waste wood constitute a valuable raw material. The Impact Hammer Mill, series PHPS converts pre-shredded residual wood and waste wood of any kind into valuable raw material for material and thermal recovery. Even contaminated materials can be processed. Heavy foreign objects in the feed material are separated and automatically discharged. Characteristics, Function Material feeding is vertically from above Heavy, rotating hammers break the material and throw it against the impact plates The wood is split along the grain and enclosed metal contaminants are set free, separated and discharged Further processing of the wood pieces is effected by stationary breaker and comb bars The end fineness is determined by the perforation of the integrated screen Split housing design allows hydraulic opening Sturdy disc rotor is stress-relieved Adjustable separation degree of the discharge chute for metal pieces Device for hydraulic hammer...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The quality and consistency of flakes have a significant influence on board properties. Knife-ring flakers are flexible and can be individually adjusted to meet flaking requirements. The professional preparation of chips leads to the right flakes for particleboard. Features, Function Chip feed system with vibration chute and magnetic drum Integrated heavy particle separator "Cleanomat" Impeller used to distribute chips Counter-rotating principle of the knife ring Chip width adjustable by knife protrusion Bottom discharge Advantages Consistent flake quality High throughput rates Quick knife changes Precise knife adjustment Uniform utilization of all knives No clogging even at high moisture content Economic to operate and maintain Robust, reliable, and durable

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Hammer Mill, series PHMS is used for the economical preparation of wood chips from round wood, residual wood, waste wood or annual plants. The wood chips are of high quality and can be directly injected for combustion, or used as flakes for briquetting and pelletizing. Due to their quality they are also used for the production of core layer and surface layer material during the production of wood-based panels. Characteristics, Function Material is fed vertically from above The gravity sifter "Cleanomat" separates heavy contaminants from the feed material Flat steel hammers rotating at high speed split the feed material into flakes Stationary impact elements support the size reduction process and relieve the screens The perforation of the screens determines the size of the flakes The symmetrically designed machine housing allows operation of the mill in both directions Rotating flat steel hammers can swing back when large foreign objects penetrate into the grinding...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Surging demand by the pelletizing industry has caused a shortage of available saw dust and shavings. Numerous industries, like wood–based panelboard producers and the power plants are forced to find alternative sources. Substitution of suitable replacements has become urgent to ensure a fibre supply and to prevent shortages. Wood chips are often the only available source. Because of increasing numbers of produc-tion lines for pellets and particleboard a shortage of small fibre, has resulted. The flake produced from wet wood chips by the optimally PHMC hammer mill, can be used as an additional source or a 100% substitute of saw dust. Advantages Processing of wet chips (moisture u > 100%) Flake preparation of chips to a coarse saw dust type material Ensure the fibre supply in existing processing lines High machine availability at lowest maintenance an labour costs Independence from saw dust supply Future-proof for the usage of different material types by simple adjustment of...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Characteristics, Function A high-performance chip bunker, which transports the most different feed materials trouble-free to the plug screw, is installed in front of the modern refiner plug screw assemblies. The new high-performance chip banker can be retrofitted to any Pallmann Refiner but can also be installed on machines from other manufacturers. Advantages Increased arrangement of the steam nozzles and more precise level monitoring for more effective presteaming of the wood chips Energy savings due to less boiling time of the wood chips Reduced bridging

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Characteristics, Function Emergency lubrication is a safety device which kicks in case of a complete failure of the power supply.It also ensures that the refiner main bearing is continually supplied with lubricant providing that the bearing is effectively protected against any damage due to inadequate lubrication.This retrofit unit mainly consists of one or more pumps, the flow meter and a drive unit for connection with the powertrain of the refiner. Advantages Protection against inadequate lubrication and severe bearing damage Reliable lubrication as long as the powertrain turns

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

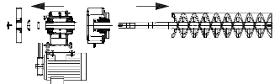

Characteristics, Function The new refiner feed screw bearing system is designed in a very maintenance-friendly wayThe bearing components, specifically the feed screw can be exchanged in no time at all and thereby increases the availability of the system.It is also possible with this design to provide the feed screw with a mechanical seal. Advantages Low downtimes Significantly increased system availability Available with mechanical seal Old feed screw can still be used

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Characteristics, Function The retrofittable optimized grinding gap adjustment for Pallmann Refiner Systems, type PR is software controlled. The grinding gap adjustment is installed operator-friendly at the rear of the main bearing of the refiner. This retrofit unit consists primarily of the control valve and a measuring device. Advantages Less components therefore less spare parts requirements Low operating- and maintenance costs Can be controlled to one hundredth of a millimeter Unsusceptible to malfunction

Request for a quoteManufacturer/ Producer

Wolfslochstraße 51

66482 Zweibrücken - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

NOVELTY STEEL

Turkey

The primary crusher selection is the key to the success of the mining, quarrying or industrial minerals operation that involves the reduction in size of rock, ore or minerals. The crushing plant can be provided with almost any type of primary rock crusher. Novelty Steel supplies; * Cone Crushers * Jaw Crushers * Gyratory Crushers * Impact Crushers * Mobile Crushers

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free