OPSYTEC DR. GRÖBEL GMBH

Germany

Manufacturer/ Producer

OPSYTEC DR. GRÖBEL GMBH

Germany

The irradiation chamber BS-02 is compact, robust equipment for the time- or dose-controlled irradiation of samples with UV radiation. The chamber can be fully equipped for one of the spectral regions UV-C, UV-B, or UV-A to achieve the highest irradiance. Alternately, the use of two separately controlled lamp groups for different spectral regions allows for especially flexible operation of the chamber. With interchangeable lamps, the BS-02 is really flexible. No tools are required for lamp replacement. The interior irradiation chamber has a base area of 49 x 32 cm² and a height of 23 cm. The sample chamber operating temperature is about 25°C - 30°C so that thermal damage to the specimen is avoided. Due to the high uniformity of the irradiation, the samples may be positioned in any order. For the BS-02 we offer two irradiation controllers, the UV-MAT and the UV-MAT Touch.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

The BS-03 is a medium-sized, rugged irradiation chamber for time- or dose-controlled irradiation of samples with UVA, UVB, or UVC. The chamber can be fully equipped for one of the spectral ranges UVC, UVB, or UVA to achieve the highest irradiance. Alternately, the use of two separately controlled lamp groups for different spectral ranges allows for especially flexible operation of the chamber. The interior irradiation chamber has a base area of 68 x 49 cm² and a height of 32 cm. The sliding sample carrier facilitates loading and unloading. With a load of up to 20 kg, this can withstand all demands. The sample chamber operating temperature is about 25°C so that thermal damage to the specimen is avoided. Due to the high uniformity of the irradiation, the samples may be positioned in any order. Two irradiation controls are available for the BS-03: the UV-MAT and the UV-MAT Touch.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

The UV test chamber BS-04 is large, robust equipment for the time- or dose-controlled irradiation of samples with UV light. The chamber can be fully equipped for one of the spectral regions UV-C, UV-B, or UV-A to achieve the highest irradiance. Alternately, the use of two separately controlled lamp groups for different spectral regions allows for especially flexible operation of the chamber. The interior irradiation chamber has a base area of 86 x 65 cm² and a height of 32 cm. The sliding sample carrier facilitates loading and unloading. With a load of up to 20 kg, this can withstand all demands. The sample chamber operating temperature is about 25°C so that thermal damage to the specimen is avoided. Due to the high uniformity of the irradiation, the samples may be positioned in any order. The BS-04 can be equipped with two irradiation controls: the UV-MAT and the UV-MAT Touch.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

The 3D UV test chamber BS-05 is a large irradiation chamber for double-sided, 3D irradiation of samples with UV or visible light. A sample plate made of stainless steel or fused silica or a rotating holder for mixing of fluids are available. Like all BS irradiation chambers, the BS-05 offers time- and dose-controlled irradiation of samples with UV light. The chamber can be fully equipped for one of the spectral ranges UVC, UVB, or UVA to achieve the highest irradiance. Alternately, the use of two separately controlled lamp groups for different spectral ranges allows for especially flexible operation of the chamber. The large irradiation chamber of the test chamber has a base area of 86 x 65 cm² and a height of 32 cm. The maximum sample chamber temperature during operation is approx. 25 °C, so that thermal damage to the samples is avoided. Due to the high homogeneity of the irradiation, the samples can be positioned as required.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

The dose controller UV-MAT continuously measures irradiances, calculates doses, and stops irradiation at the set target dose. Two spectral ranges can be separately controlled. Thus, UV-MAT ensures a constant dose independent from lamp aging, temperature, and pollution. The measurements are made with calibrated radiometric sensors. The built-in diffusers ensure the cosine correction that is required for non-vertical irradiation. The sensor contains an extremely precise analog-digital converter and a temperature sensor. The integrated diffuser ensures the required cosine correction. Excellent long-term stability is achieved through the use of appropriate materials. The sensors are calibrated with traceability to PTB (Physikalisch Technische Bundesanstalt, the German national test authority); after being calibrated, they are supplied with a factory calibration certificate.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

By modern UV LED technology, the chamber BSL-01 reaches a high irradiance of up to 800 mW/cm². Despite its compact dimensions, the UV LED chamber BSL-01i reaches a 80-fold irradiance compared to our classical irradiation chambers. As a compact tabletop unit, the BSL-01i is perfectly suitable for laboratories and manufactory. For different applications, the wavelengths 365 nm, 385 nm, 395 nm, 405 nm and 450 nm are available. Optionally, two wavelengths can be controlled separately. This means that the irradiation chamber can be perfectly adapted to the photoinitiator‘s requirements and is ideal for laboratory use or product changes. A nearly airtight design with separate gas inlets and outlets allow irradiations under inert conditions. For this purpose, we recommend using nitrogen as a scavenging gas with a slight overpressure. The measurement of the O2 concentration can be optionally performed at the rear gas outlet for this purpose.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

With the UV LED chamber BSL-02, we offer you a versatile irradiance chamber on a basis of high quality UV LEDs. The most common UV curing adhesives can be applied, due to the high irradiance of 400 mW/cm². Compared to our irradiance chambers of the series BS, the series BSL-02 offers the 40-fold irradiance. In addition, the high irradiance allows for very short exposure times. With the typical UV LED characteristics like „Instant-Start“, the dimmability and the long service life, the BSL-02 is ideal for laboratory tests and the manual production. The irradiance is adjustable from 2% to 100%. The integrated timer controls the irradiance precisely. For even better results, we recommend one of our calibrated UVA+ sensors. The dose control is already integrated in the UV-MAT Touch and UV-MAT control units in the BSL-02 UV LED chamber.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

The UV LED chamber BSL-03 is the second largest irradiation chamber in the BSL series. The high irradiance combined with the exact dose control offers a unique reproducibility for perfect results! Due to the irradiance of up to 220 mW/cm², it is possible to use the most common UV curing adhesives or lacquers. For high irradiances, the UV LED chamber can be ordered completely with one LED wavelength. A particularly flexible application is possible when two separately controllable LED wavelengths are ordered. Compared with our irradiation chambers of the BS series, the BSL-03 offers an irradiance that is 22 times as high. The high irradiance allows for extremely short exposure times. With the high homogeneity of the irradiation, the samples can also be positioned as needed. Due to the typical characteristics for UV LEDs, such as “immediate start”, the dimmability and the high durability, the BSL-03 is ideally suited for medium-sized laboratory tests and curing of large components.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

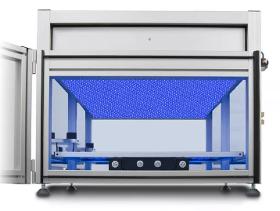

The UV LED chamber BSL-04 is the largest irradiation chamber in the BSL series. The high irradiance combined with the exact dose control offers a unique reproducibility for perfect results! The wavelengths 365 nm, 385 nm, 395 nm, 405 nm and 450 nm are available for your application. Due to the irradiance of up to 110 mW/cm² and the high homogeneity, even very large parts or batches can be irradiated. For high irradiances, the UV LED chamber can be ordered completely with one LED wavelength. A particularly flexible application is possible when two separately controllable LED wavelengths are ordered. Compared with our irradiation chambers of the BS series, the BSL-04 offers an irradiance that is 14 times as high. The high irradiance allows for extremely short exposure times. With the high homogeneity of the irradiation, the samples can also be positioned as needed.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

The irradiation chamber BS-02CT is a chamber to test samples according IEC 60335-1: “Household and similar electrical appliances – Safety – Part 1: General requirements - Edition 5.2” This test is designed for non-metallic materials that are exposed to direct or reflected UVC radiation from 200 nm to 280 nm. The test can be used to test radiation stability against UVC radiation that can cause aging like discolorations, changes in material properties, crack formation and smell. Therefore the UVC low pressure mercury lamps emit a continuous spectral irradiance of 10 W/m² at 254 nm. IR heater heat up the samples so that a black-panel temperature of 63 °C ± 3 °C can be reached and controlled. The time can be set to an exposure duration of 1000 h. The irradiation chamber BS-02CT can also be used to test material properties that are disinfected by UV-C. Typically the UVC dose of a daily disinfection for a period of two years can be accelerated to 12 hours.

Request for a quoteManufacturer/ Producer

Am Hardtwald 6-8

76275 Ettlingen - Germany