MIFA ALUMINIUM B.V. - Rely on the power of precision

Netherlands

Manufacturer/ Producer

MIFA ALUMINIUM B.V.

Netherlands

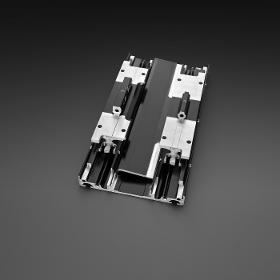

Mifa has an extensive range of modern CNC-controlled machinery. Nevertheless, we prefer to use machining work as little as possible. Thanks to the combination of precision extrusion, CNC machining, and surface treatment, we can shorten the total production time for machining and improve the quality of the product. We write the software ourselves and make our own moulds for the CNC machining. Every profile is different and often demands a specific processing method, particularly if it is a visible surface. To this end, we use CAD/CAM programmes such as Solid Works, Solid Edge, and Unigraphics. We also develop the clamping tool ourselves too. The right clamping method is crucial in order to achieve the desired result. The best clamping method is dependent on factors including the dimensions and thickness of the profile and the processes to be implemented. For more text and explanations about our CNC and aluminium machining possibilities, please contact us.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

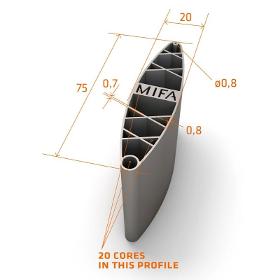

EN-755-9 and EN-12020-2 are the accepted norms for the extrusion of aluminium profiles. They allow deviations of 0.15 mm or more. Mifa ignores these norms and applies precision extrusion of 0.02 mm. We’re unique in the world! And it gives countless possibilities. Bulk production. Standardised work. Inaccurate. These are words that you’ll hear often if you ask engineers for the features of extrusion. But there is another option. Mifa’s delivery starts from 10 kg, and we offer custom-built products and precision, also for straightness, torsion, concentricity, parallelism, surface roughness and tting. Add to this the outstanding features of aluminium – post-processing is often not needed – and it becomes clear that precision extrusion would be useful for many applications. Even as a replacement of other techniques and materials.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Anodizing, galvanizing, passivation, painting: Mifa offers customers all possible surface treatments. A good surface treatment can protect against corrosion, reduces wear or friction, can be electrically insulating or conductive, and in many cases makes the product visually more attractive. Mifa sees surface treatment as the nishing touch that not only increases durability but also adds extra functionality to the aluminium product. The main surface treatments for aluminium that Mifa offers can be roughly divided into three categories: - Conversion layers: aluminium passivation, anodizing, and plasma electrolytic oxidation - Galvanic coatings: chemical nickel-plating, silver, gold, tin, hard chromium etc. - Organic coatings, painting, paint primers, adhesive primers CVD (Chemical Vapour Deposition), PVD (Physical Vapour Deposition), and synergistic coatings can also be applied on request.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Proper bending of aluminium and magnesium requires specific knowledge of the material. The phase in the process in which the material is bent is also crucial to the final result, right after pressing or only after hardening, for example. There are many techniques for bending, such as roll forming, press (brake) bending, swivel bending, deep drawing, stretch forming, and 3D bending.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

In our assembly department, we assemble components into semi-finished or complete products. These often involve Mifa components and components supplied by the client or purchased externally. This allows us to assemble the profiles we produce into complete end products. We prefer to deliver a complete component. This is why we also perform other processes in-house, such as assembly, bending, sealing, soldering, welding, and masking. With our knowledge and experience, we know how to apply the right technology for each product. Along with machining and surface treatment (please read our respective whitepapers on our website), the other processes enables us to provide the most optimum product. We have many processes and related knowledge in-house. The customer can leave it all to us, and this also means a reduction of logistics operations, which is beneficial to the quality of the final product while also reducing costs.

Request for a quoteManufacturer/ Producer

Rijnaakkade 6

5928 PT Venlo - Netherlands