- europages

- >

- Machine tools - metal machining

- >

- LVD

- >

- products

LVD - SHEET METALWORKING MACHINERY AND SOFTWARE

Belgium

Manufacturer/ Producer

LVD

Belgium

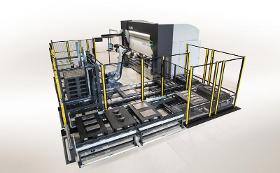

Our Compact Tower (CT-P) loads, unloads and stores raw materials, skeletons and finished parts for automated production. The CT-P system creates a flexible manufacturing cell able to operate unmanned around the clock for top productivity. A space-saving design enhances optimal material flow for uninterrupted processing of punched parts. Pallet construction is designed for compact set up and convenient forklift manipulation. KEY FEATURES 6 or 10-pallet configuration Pallet construction designed for compact set up and convenient forklift manipulation Intuitive touch screen graphical user interface Spreading magnet, air gun and peeling cylinder sheet separation devices Integrated or retrofitted to specified models Includes autoload interface PRODUCTIVITY-ENHANCING OPTIONS Integrated or retrofitted to specified models MODELS Available for VX, V, M and PX Series punch presses Specifications Available models 2500 x 1250 mm and 3048 x 1524 mm Handles sheet weights up to 100 kg

Request for a quote

LVD

Belgium

HIGHLY FLEXIBLE AUTOMATION SYSTEM One of the most flexible automation systems available for punching. The FA-P system can handle small and large volume applications with common material type, thickness and size and small as well as large work pieces. FA-P offers advanced load/unload, part picking and a large area for stacking punched parts directly onto the allocated pallet - with no operator intervention of additional automation required. KEY FEATURES Automated production from stored raw material to stacked finished part Fast loading system Automatic sheet thickness control and automatic sheet separator devices ensure efficient material loading Intuitive touch screen graphical user interface PRODUCTIVITY-ENHANCING OPTIONS Second loading pallet Part picking and sorting for scratch-free unloading Full integration with an existing warehouse MODELS Available for VX and PX-1530 Series punch presses

Request for a quote

LVD

Belgium

The Extended Tool Magazine (ETM) for Strippit PX punch presses holds up to 40 additional tools and up to 400 tools with the use of indexable multitools. ETM adds tooling capacity, reduces tool changeover time, and increases the efficiency of punching operations. Tools can be loaded and unloaded while the machine is punching. For automated production, the ETM can be combined with a Flexible Automation system (FA-P) or a Compact Tower (CT-P) for loading/unloading, material storage and retrieval. KEY FEATURES Holds up to 40 punch/die combinations, up to 400 tools using indexable multitools Wheel configuration for easy tool access ETM can be loaded and unloaded while the machine is operating Tool life monitoring records the number of hits for each tool Touch-P manages the tooling inventory; identifies the tools required and preloads them into the machine magazine Touch-P touch screen control is intuitive and simple to use PERFORMANCE-ENHANCING OPTIONS

Request for a quote

LVD

Belgium

Ulti-Form takes automated bending a step forward with a ToolCell-inspired automated tool changing press brake using a built-in tooling warehouse and equipped with Easy-Form® Laser adaptive bending technology. Programming for both the press brake and robot is handled offline with no robot teaching needed. An auto-adaptive robot gripper designed by LVD automatically adjusts to the workpiece size, allowing different part geometries to be processed without a gripper change. KEY FEATURES Automated tool changer press brake reduces setup time Easy-Form® Laser adaptive bending technology ensures part accuracy KUKA robot and press brake work in synergy to minimize changeover time Programming is handled completely offline, no robot teaching Auto-adapting, universal gripper handles part sizes from 50 x 100 mm up to 1200 x 800 mm High productivity in a compact space, including three input pallets and output zone for up to 10 pallets Automated pallet dispenser and conveyor

Request for a quote

LVD

Belgium

The ToolCell makes any bending application easier and more productive using revolutionary bending automation technology that minimizes setups, is fast and highly reliable. An integrated automated tool changing system stores a library of top and bottom tooling. All tools are held within the machine and automatically changed as the job requires – significantly minimizing tool changeover time for better bending productivity. LVD’s patented Easy-Form® Laser in-process angle monitoring and correction technology ensures the first part is a good part. KEY FEATURES TOUCH-B touch screen graphical user interface control is intuitive and simple to use All tools held within the footprint of the machine Large library of tools: 2 complete lengths of self-seating top tooling (punches) and 5 complete lengths of bottom tooling (Vee dies) Flexible tooling configuration Automated tool loading and unloading Equipped with Easy-Form Laser Precise set-up for every job – No fine adjustment of tool stations

Request for a quote

LVD

Belgium

The Easy-Form precision press brake delivers top-of-the-line performance – high accuracy and productivity. This ultimate bending machine, based on the PPEB Series design, is enhanced with LVD’s patented Easy-Form® in-process angle correction and monitoring system. Easy-Form monitors the angle of the bend in real time and provides instant feedback to the TOUCH-B control so that each part is formed to the correct angle from the very first bend. KEY FEATURES Patented Easy-Form® in process angle monitoring and correction system TOUCH-B touch screen graphical user interface control is intuitive and simple to use Bending parameters automatically controlled by LVD's unique 'intelligent' learning database 2D & 3D color graphics simulate part creation and display material handling sequencing CNC crowning V-axis standard for models over 2 meters Press brakes up to 400 ton/4 meter are designed and built using a welded one-piece frame for machine precision Enhanced Energy Reduction System (ERS)

Request for a quote

LVD

Belgium

PPEB Series press brakes offer high precision and flexibility. Equipped with state-of-the-art hydraulics and electronics and offered in multi-axis configurations, the PPEB can tackle bending applications from simple to complex, efficiently and cost effectively. LVD’s intelligent bend database is used to automatically optimize each part program to eliminate trial bending and reduce the time it takes to bend a quality part. KEY FEATURES TOUCH-B touch screen graphical user interface control is intuitive and simple to use Bending parameters automatically controlled by LVD's unique 'intelligent' learning database 2D & 3D color graphics simulate part creation and display material handling sequencing CNC crowning V-axis standard for models over 2 meters Press brakes up to 400 ton/4 meter are designed and built using a welded one-piece frame for machine precision Enhanced Energy Reduction System (ERS) Turbo hydraulics (standard on 220-ton modeland higher) PERFORMANCE-ENHANCING OPTIONS

Request for a quote

LVD

Belgium

PPED Series press brakes are practical and easy to use – perfect for general-purpose bending. A cost-effective design combined with LVD precision and reliability delivers true application flexibility. An intuitive touch screen control combined with LVD’s easy to use software makes programming and setup quick and simple for every level of user. Offered in a range of models, in manual and CNC configurations, there’s a PPED machine to fit most applications. KEY FEATURES TOUCH-B touch screen graphical user interface control with 3D simulation is intuitive and simple to use 4-axis CNC back gauge (X, R, Z1, Z2) Robust hydraulic system with automatic tilt control CNC crowning table (not available on 50 or 80-ton models) PERFORMANCE-ENHANCING OPTIONS Lazer Safe guarding system Second foot pedal Vertical W-style, LVD style (European style with adapter) or universal tooling style CADMAN-B programming software MODELS PPED-4: 2-axis backgauge (50 tons by 2 meter up to 320 tons by 4 meter)

Request for a quote

LVD

Belgium

The Dyna-Cell features the high-speed Dyna-Press Pro electric press brake coupled with an industrial robot. The compact, integrated unit automates the bending of small- to medium-sized parts in varying batch sizes at speeds of up to 25 mm per seconds. Dyna-Cell offers maximum bending productivity in a compact footprint of 5 m x 5 m. KEY FEATURES Optimum cost-benefit ratio Fast, electric-drive press brake Lightweight Kuka industrial robot Start final production after <10 minutes CAM and <10 minutes setup Unique gripper that fits all part sizes from 30 mm x 100 mm up to 350 mm x 500 mm Space for two input pallets, two unloading pallets or boxes (Euro pallet size) Intuitive 15” Touch-B touch screen control Fully integrated with LVD's CADMAN® software suite Unmanned or manned operation PERFORMANCE-ENHANCING OPTIONS Easy-Form® Laser system CADMAN-B programming software W-style or universal tooling MODELS

Request for a quote

LVD

Belgium

The Dyna-Press is your perfect bending partner. The electric drive Dyna-Press delivers fast bending speeds of 25 mm per second to bend more parts per hour at a lower cost per part. Ideal for bending small and simple parts, its ergonomic design permits use in a standing or seated position. Add to this impressive production capabilities, easy to use control and compact size for a press brake that is fast, accurate and flexible. KEY FEATURES Compact design uses minimal floor space Easy transport with a standard forklift (except 40/15) Intuitive touch screen control Touch-B High repeat accuracy with 4-axis back gauge, 5-axis on Pro model PERFORMANCE-ENHANCING OPTIONS Extra gauge finger Safety sytem Air conditioning unit for electrical enclosure Vertical W-style or universal tooling CADMAN-B programming software MODELS Dyna-Press 24/12 Dyna-Press 40/15 Dyna-Press 40/15 Pro

Request for a quoteManufacturer/ Producer

Nijverheidslaan 2

8560 Gullegem - Belgium

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy.

Request for a quote

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy. Types of products we manufacture Glass coaters and packaging machines in the vacuum industry Baseplates and chassis for the oil & gas and energy industries Winches and crane components for the naval industry Pressure vessels from carbon steel and stainless steel PROJECT MANAGEMENT DESIGN & ENGINEERING CUTTING ASSEMBLING & WELDING PRESS BREAKS FOR BENDING ROLLING MACHINING HEAT TREATMENT SURFACE TREATMENT FINAL ASSEMBLY & AUTOMATION CUSTOM PACKAGING & DISPATCH

Request for a quote

EMSIL TECHTRANS SRL

Romania

Retrofit your machines to enjoy the modern age

Request for a quote

EMSIL TECHTRANS SRL

Romania

displaceable rotary tables are intended for increasing the technological possibilities of the horizontal boring and milling machines with moving column

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free