- europages

- >

- Business Consultancy

- >

- LEAN REŠITVE

- >

- products

LEAN REŠITVE - Business Process Optimization : Using Lean Methods

Slovenia

Service Provider

LEAN REŠITVE

Slovenia

Lean processes: the basis of successful transformation They are the best tool on the path to excellence, achieving lasting progress and adapting business to customer requirements . The practical workshop will present in an interesting and interactive way the views and challenges that companies face in maintaining economic performance and growth . Lean processes are the basis for successful digital transformation Any organization that wants to be successful and leader in its industry in the long run must take care of the best possible use of resources and better cost management . You will be introduced to how development takes place excellent processes in a lean organization , which are a prerequisite for digital transformation . In the implementation of lean manufacturing / logistics and digital transformation employees are key to success. We will present examples of how to connect all stakeholders

Request for a quote

LEAN REŠITVE

Slovenia

is a link between lean manufacturing and Industry 4.0, assuming they complement and reinforce each other In the last few decades, the manufacturing sector has experienced a transition from artisanal production to mass production and from mass production to lean production. Lean manufacturing, derived from Toyota’s manufacturing system, is a philosophy that simplifies procedures to reduce losses and increase resources. Today, Lean is widely recognized as best practice for manufacturing companies worldwide. Lean has thus succeeded and accepted in improving performance and fostering competitiveness that its implementation has been extended to other non-manufacturing sectors such as healthcare, construction, logistics, banking and telecommunications. The upgrade is Lean 4.0, which is transitioning to digitizing methods.

Request for a quote

LEAN REŠITVE

Slovenia

5S method - An orderly workplace in the introduction of lean processes is the foundation of lean or. Lean production. It is a systematic approach to the organization, standardization and removal of distractions in the work environment. The 5S method comes from Toyota, which set itself the goal of a tidy and clean work area and radically changed the culture of the company’s employees between 1948 and 1975. The support and motivation of the company’s management is crucial at this starting point. Lean or Lean production based on: TPM , 5S method, Kaizen, SMED and SFM methods are indispensable elements of any organization that wants to successfully compete in the global market. At the beginning of the implementation of lean production, we propose the 5S (6S) method to all our customers, which is one of the basic methods of lean production.

Request for a quote

LEAN REŠITVE

Slovenia

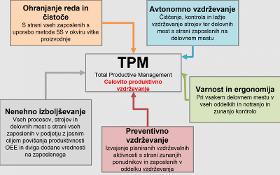

TPM method - comprehensive productive maintenance TPM method – Total productive maintenance or comprehensive productive maintenance is a method – project – mentality, which very intensively interferes with the habits and methods of work of both maintenance and production. A well-maintained fleet is the basis for high efficiency – productivity. The approach itself, the introduction of the method, depends on the correct strategy and setting up the organization TPM, which will take care of the gradual introduction of the method in the context of lean production. It is also crucial to choose the right TPM coordinator, who leads the internal project and takes care of the smooth work of all TPM teams. The responsibilities of the TPM coordinator depend on the size of the company and the intensity of the implementation itself. We can say that this is 1. method in efficient production.

Request for a quote

LEAN REŠITVE

Slovenia

Smed method - quick changes The SMED method, or the quick change method, helps us reduce the time it takes to change a tool or product in the work process. Due to the growing number of product versions and the size of the batches we produce, the SMED method can achieve very large savings in the availability of our working resources. Changes in the economic environment require companies to respond flexibly to the changing demands of their customers. Therefore, a rapid change process is needed. If a company has a large product portfolio, there are basically only two options; integrate production into large batches or change the production program frequently. Frequent changes associated with the machine replacement process are optimized using the SMED method.

Request for a quote

LEAN REŠITVE

Slovenia

KAIZEN - Continuous Improvement is in its most basic translation the Japanese term meaning “continuous improvement” KAIZEN – continuous improvement – is also a culture and framework for managing ongoing change that can help companies improve their operational processes The implementation of Kaizen depends on the use of different tools and in some cases also a specific type of Kaizen

Request for a quote

LEAN REŠITVE

Slovenia

7 losses - in Lean, all activities that consume resources but do not bring any value to the end customer are marked as loss. In fact, they are activities that really create value for customers, only a small part of the overall work process. Everything else can be classified into one of 7 losses. In the original, this is a seven-loss method, we added an eighth, untapped human potential. The types of 7 losses are: EQUIPMENT / DEFECTS EXCESSIVE PRODUCTION UNNECESSARY MOVEMENT TRANSPORT WAITING INVENTORIES EXCESSIVE PROCESSING (PROCESSING) UNUSED HUMAN POTENTIAL

Request for a quote

LEAN REŠITVE

Slovenia

SFM-Morning meetings in production (shop flor managment) The system of regular meetings (Morning meetings in production) or SFM is an excellent system that we recommend to all companies for good information transfer. Many factories have set up corners for SFM meetings where workers and their managers can meet. SFM (Shopfloor management) makes it easier for us to manage production processes at the operational level. SFM - Morning meetings in production - main advantages: Raise operational efficiency through standard operations Improved information flow Reduction of errors in the manufacturing process Disclosure of gaps in production or processes. Raising employee productivity Positive effect on RVC

Request for a quote

LEAN REŠITVE

Slovenia

Gemba walk! What is it? The term Gemba walk is derived from Japanese and means “real city” or “crime scene”. At Lean, “gemba” is the most important place for a team, as it is a place where added value is created. It is a very important part of the lean management philosophy. The purpose is to enable managers and managers to observe the actual work process, work with employees, gain knowledge about the work process and find opportunities for continuous improvement. The operator is best aware of all the problems that arise in the work process and is an excellent source of information. Before you start a tour, you need to have a plan that depends on your long-term and specific goals. You can use a checklist of questions to help you clarify the process

Request for a quote

LEAN REŠITVE

Slovenia

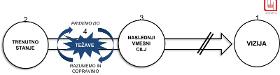

Process optimization - how to get started? Any company that wants to maintain improved processes in the long run must first consider a vision, direction or goal (1). The most effective way to successfully motivate employees is clear communication of vision, direction and goals. Process optimization requires a change in the current way of working, so it is very important for employees to identify with the vision, direction and goals of the company. Once the direction is confirmed and agreed, the current situation needs to be effectively analyzed to optimize the process (2). Understanding the current situation without subjective ballast is the key to effective process optimization. Employees directly involved in the process participate in the analysis of the current situation and systematically present the current situation using lean methods.

Request for a quoteService Provider

Kidričeva Ulica 24

SI-3000 Celje - Slovenia