INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Manufacturer/ Producer

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The floating self-clinching nut has the special feature of allowing couplings even when there is a misalignment in the holes of the coupled objects. It is degned in two different versions: with a normal threaded hole and with a self-locking threaded hole. The nut can float up to 0.4 mm from the center, in all directions. The maximum total movement is 0.8 mm This self-clinching nut is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch. The sheet metal experiences plastic deformation and locks the fastener firmly to itself. The nut is fully installed when the sheet sits flush with the anvil face. So the result is aesthetically perfect and provides high tensile as well as torsional strength

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The self clinch standoff is an element in which the head is fully concealed in the sheet metal; it offers high torsion and tensile strength characteristics. The application is so aesthetically sound that no further finishing work is required after installation. It is particularly suitable for the electronics industry This self-clinching standoff is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch, applyinng only sufficient pressure to squeeze the hexagon head into the parent sheet. The sheet metal experiences plastic deformation and locks the fastener firmly to itself. After installation the head should be flush with the sheet. So the result is aesthetically perfect and hexagon head provides high tensile as well as torsional strength

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The self clinch standoff is an element in which the head is fully concealed in the sheet metal; it offers high torsion and tensile strength characteristics. The application is so aesthetically sound that no further finishing work is required after installation. It is particularly suitable for the electronics industry This self-clinching standoff is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch, applyinng only sufficient pressure to squeeze the hexagon head into the parent sheet. The sheet metal experiences plastic deformation and locks the fastener firmly to itself. After installation the head should be flush with the sheet. So the result is aesthetically perfect and hexagon head provides high tensile as well as torsional strength

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

This self-clinching broaching nut for plastic materials is widely used in the electronics industry. It offers a threaded hole of high resistance to both torsion and tensile strength This self-clinching nut is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch. The parent material experiences plastic deformation and locks the fastener firmly to itself Standard material: Electro tin plated steel and stainless steel

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

This self-clinching broaching standoff for plastic materials is widely used in the electronics industry. It offers a threaded hole of high resistance to both torsion and tensile strength and allows panels to be spaced at the desired distance This self-clinching standoff is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch. The parent material experiences plastic deformation and locks the fastener firmly to itself Standard material: Electro tin plated steel and stainless steel

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

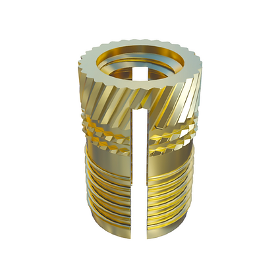

The S10 are self-tapping thread forming inserts to be installed into cylindrical holes Best suited for ductile, softer thermoplastics or thermosets They provide the best pull-out resistance for a post-mold installed inserts Very easy installation, also using a simple screwdriver Symmetrical shape, they do not need to be oriented during installation process, thus can also be easily used in automatic systems Inch versions from 4-40 to 1/4-20 also are available on request

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The THREAD-SERT are self-tapping inserts to be installed into cylindrical holes Suitable for installation in a wide range of thermoplastics and thermosets They are particularly designed for applications that may involve a high tensile load Very easy installation, also using a simple screwdriver Available in two versions with o without head. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. This feature is also useful in applications with electrical contacts Also known as SCREW-SERT, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The EXPANSION-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoset plastics Due to its diamond knurled design, this insert penetrates for a minimum length within the hole walls without decreasing tensile strength. This feature makes it ideal for applications in hard thermoset plastics They are recomended for applications where high resistance values are not required They are installed by simple pressure, without the need for special equipment Headed (flanged) and reverse-headed (reverse flanged) versions are also available. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. In inverted flange inserts, a screw can be inserted on the opposite side of the flange, offeing very high pull-out resistance Also known as BANC-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S50, S51 are press-in inserts to be installed into cylindrical holes Suitable for soft thermoplastics The helical knurl of the outer surface is specially designed to facilitate insertion by allowing maximum plastic sliding of the material in the serration grooves They allow easy and low-cost assembly, as no special machinery is required Offer moderate pull-out and good torque resistance They are available in unheaded S50, and headed (flanged) S51 versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. In the S51 a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications The S50 in addition are symmetrical so they do not need to be oriented during installation process.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The PRESS-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoplastic materials The combination of flat and knurled areas ensure high torque and pull out performance normally achievable only with inserts that are installed by a hot/ultrasonic process These inserts are installed by simple pressure, without need for special equipment Also known as PRESS-LOK, with equivalent shape, features and dimensions

Request for a quoteManufacturer/ Producer

VIA NOVARA 1

20063 Cernusco Sul Naviglio - Italy