INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Manufacturer/ Producer

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

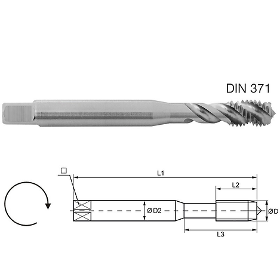

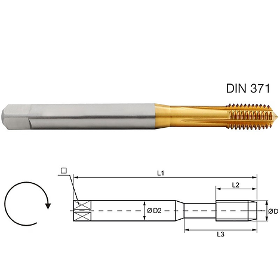

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Oversized diameter 6H+0.1mm Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H+0.1mm Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. + 0,1 mm oversize for electroplating allowance ≈ 25 µm thickness. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

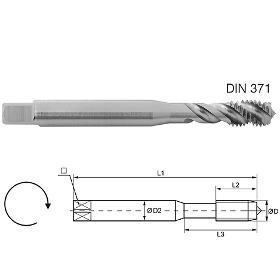

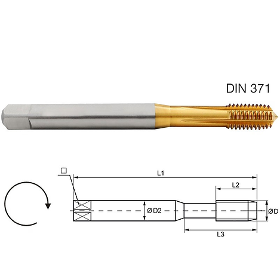

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Undersized diameter 4H Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO1/4H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Fine Tolerance 4H (ISO1) for close fit bolt connection. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

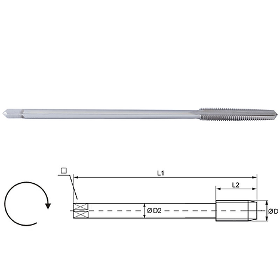

Thread standard: Metric, ISO DIN 13 Type: Machine nut tap Application: General use Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 850 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Maschine Nut tap for through holes with long shank for taking some thread cutted nuts. For thread depth up to 1,0 times diameter. Also useable for thread cutting in awkward places. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

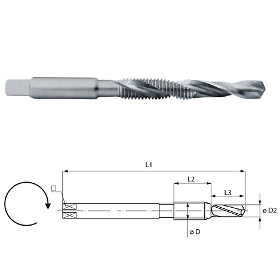

Thread standard: Metric, ISO DIN 13 Type: Combined machine tap (core hole drilling and thread tapping) Application: Combined (core hole drilling and thread tapping) Material of product: HSSE Surface treatment: no For materials: Materials of medium mechanical strength (alloyed and non-alloyed steels up to 600 N/mm², Malleable cast iron, Graphite cast iron, Copper, Brass, Aluminium, Aluminium-magnesium alloys, Zink alloys, Red bronze, Electron metall, Pressure-cast zink) Tensile strength up to: 600 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Combined machine taps enables the user to produce the tapping drill hole and the through thread in one operation without any tool changing. The tool incorporates a twist drill before the thread-tapping part. It is possible with this tool to produce through threads up to a maximum threaded depth of 2 x D. It is sensible to use this tool on machines possesing an RPM switchover facility for drilling and tapping.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine forming tap Application: General use Material of product: HSSE Surface treatment: TIN For materials: Steel, Stainless steel, Cast aluminum, Coper, Brass etc* Tensile strength up to: 850 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6HX The Forming tap has improved geometry for an optimal processing of a big range of materials. The lubrication grooves provide the necessary lubrication to depths of 2.5 D. Advantages: no chips up to 20 times longer lifetime (compared to taps) same forming tap for through hole and blind hole wide range of materials can be processed intersection of the thread is impossible no pitch or flank angle errors increased strength of the thread through material deformation higher surface quality much higher cutting speed Please be aware to reach enough cutting speed, so that the material can optimally plasticized. Only for machine use.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine forming tap Application: Oversized diameter 6GX Material of product: HSSE Surface treatment: TIN For materials: Steel, Stainless steel, Cast aluminum, Coper, Brass etc* Tensile strength up to: 850 N/mm2 Standard: DIN 371/376 Tolerance: ISO3/6GX Tolerance ISO3/6GX – Thread with large clearance. The Forming tap has improved geometry for an optimal processing of a big range of materials. The lubrication grooves provide the necessary lubrication to depths of 2.5 D. Advantages: no chips up to 20 times longer lifetime (compared to taps) same forming tap for through hole and blind hole wide range of materials can be processed intersection of the thread is impossible no pitch or flank angle errors increased strength of the thread through material deformation higher surface quality much higher cutting speed Please be aware to reach enough cutting speed, so that the material can optimally plasticized. Only for machine use.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

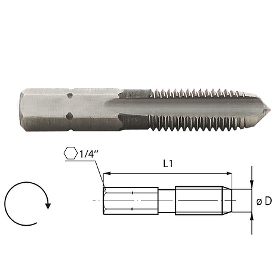

Thread standard: Metric, ISO DIN 13 Type: Machine bit tap Form D, for through and blind holes Application: General use Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: Factory standard Tolerance: ISO2/6H Bit taps have been designed for thread cutting using battery-powered screwdriver drills and electric hand drills with right-hand and left-hand rotation. But they are also suitable for thread cutting by hand or in a stationary drilling machine. Your battery-powered screwdriver drill should have a minimum power of 7.5 Volts. Take care that the tool and the axis of the hole are exactly aligned and use a suitable cutting oil. For thread cutting we recommend using battery-powered screwdriver drills and electric hand drills with lowest rotaionsettings (0 - 450 RPM) and maximum torque settings.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

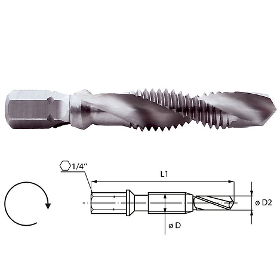

Thread standard: Metric, ISO DIN 13 Type: Combined machine bit tap (core hole drilling and thread tapping) for through holes Application: Combined (core hole drilling and thread tapping) Material of product: HSSG Surface treatment: no For materials: Materials of medium mechanical strength, non ferrous metals and thermoplastics Tensile strength up to: 600 N/mm2 Standard: Factory standard Tolerance: ISO2/6H Combined Bit taps have been designed for drilling, tapping and deburring in one operation using battery-powered screwdriver drills and electric hand drills with right-hand and left-hand rotation, but they are also suitable for thread cutting in a stationary drilling machine. It is possible with this tool to produce through threads up to a maximum threaded depth of 1 x D. They are especially usefull for mounting an dsmall batch production. Take care that the tool and the axis of the hole are exactly aligned and use a suitable cutting oil.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

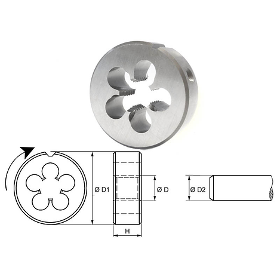

Thread standard: Metric, ISO DIN 13 Type: Round die Application: For stainless steel Material of product: HSSE Spiral entry: yes For materials: Stainless steel (INOX, V2A, V4A etc.) Tensile strength up to: 1200 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Special geometry for Stainless steel. Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

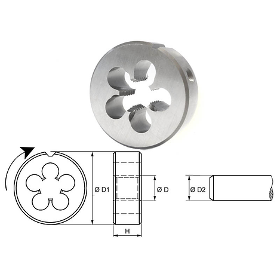

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Round die Application: For brass Material of product: HSS Spiral entry: yes For materials: Brass (short and long chipping) Tensile strength up to: Standard: DIN 223 Tolerance: ISO-6g Special geometry for brass. Lapped for sharp cutting edges, smooth surface and increased tool life time. Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quoteManufacturer/ Producer

VIA NOVARA 1

20063 Cernusco Sul Naviglio - Italy