- europages

- >

- Plain bearings

- >

- IGUS® GMBH

- >

- products

IGUS® GMBH - motion plastics® - tech up, cost down!

Germany

Manufacturer/ Producer

IGUS® GMBH

Germany

iglidur® knife edge rollers Precise and lubricant-free deflection igus® has developed its own knife-edge conveyor pulleys to implement conveyor belt deflection for conveyor technology applications. The first standard product range has three iglidur® materials available: the universal iglidur® P210 and the FDA compliant iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power. Complete freedom from the lubricant of the belt deflection Low driving power Tight deflection radii Long service life of the belt Cost-effective High holding times Application areas: Packaging, material handling, automation, food processing. Brochure (PDF) Shaft diameter d1 [mm]: Knife-edge conveyor pulley application example Precise and lubricant-free deflection igus® has developed its own knife-edge conveyor pulleys to implement conveyor belt deflection for conveyor technology applications. The first standard product range has three iglidur® materials available: the universal iglidur® P210 and the FDA compliant iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power. Complete freedom from the lubricant of the belt deflection Low driving power Tight deflection radii Long service life of the belt Cost-effective High holding times Application areas: Packaging, material handling, automation, food processing. Brochure (PDF) Shaft diameter d1 [mm]: Soft stainless steel Hard stainless steel

Request for a quote

IGUS® GMBH

Germany

iglidur® H1: The endurance runner for high temperatures iglidur® H1 is the first choice when high holding times are required in extreme environmental conditions. Extreme wear resistance is coupled with excellent resistance to temperature and chemicals - not only in the packaging and foodstuff industries or the automotive industry. iglidur® H1 is available as cylindrical bearings and plain bearings with flange. High wear resistance in extreme ambient conditions Very low coefficients of friction High resistance to temperature and chemicals For applications in the engine compartment

Request for a quote

IGUS® GMBH

Germany

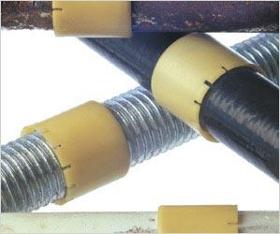

iglidur® rollers in application 14HMInews.wmv Material data of the iglidur® elastomeric bandage Density: 1,25 g/cm³ Flexural E-modulus (DIN 53457): 130 Shore D hardness (DIN 53505): 50 Maximum long-term service temperature: 80 °C Maximum short-term service temperature: 110 °C Lower application temperature: - 40 °C Specific volume resistance:: <10¹² Ωcm Surface resistance: <10¹¹ Ω

Request for a quote

IGUS® GMBH

Germany

Shaft diameter d1 [mm]: Request iglidur® multi-component bearing Even higher loads The new iglidur® multi-component bearing combines the benefits of a hard polymer shell and a tribooptimized iglidur® core to make a unique bearing: Service lives previously not achieved in with an injection- molded polymer bearing heavy duty pivoting applications even beyond a radial load of 120 MPa show the potential. Lubrication-free wear-resistant Extremely shape stable Corrossion-resistant Application areas: Agricultural engineering, utility and construction vehicles, mechanical engineering Dimensions according to ISO 3547-1 and special dimensions Chamfer depending on d1 d1 [mm]: f[mm]: Ø 1-6 0,3 Ø 1-6 0,5 Ø 1-6 0,8 Ø > 30 1,2 Shaft diameter d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

iglidur® sealing lip bearing d1 [mm]: Quick and easy-to-mount polymer bushing made of iglidur® J (JDSM) or iglidur® V400 (VDSM) with clip-on radial shaft seal ring as sealing for the rotating shaft. Seals off against dirt, dust as well as all pressure-less media. Polymer bushing with clip-on radial shaft seal ring Sealing for rotating shaft Temperature application range like iglidur® J Coefficient of friction only 10% higher than in iglidur® J Coefficients of friction identically exceptional like iglidur® J Reduced installation space as well as easy and simple mounting Realizable with numerous sealing types High-temperature option VDSM possible Temperatures till 150° C Material: iglidur® J High temperature option VATM, iglidur® V400 Seal ring made of fluorelastomer Bearing-sealing combinations for other applications on request When to use it? When the penetration of dirt and spray water should be prevented When only a small installation space is available in the axial direction When an existing seal should be integrated in a plain bearing When not to use it? When pressurized media should be sealed When absolute impermeability to the shaft and housing is needed continuously We'll gladly do the developing with you iglidur® sealing lip bearing d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

iglidur® JATM, metric d1 [mm]: iglidur® JATM/VATM consists of a hard-anodized ring and a bearing ring made of iglidur® J (JATM) and iglidur® V400 (VATM). These glide pairings fetch low coefficients of friction and high wear resistance - without lubrication. Special features Maintenance-free plain bearing system For high service performances High stiffening Simple installation Material: iglidur® J High temperature options VATM, iglidur® V400 More dimensions and supplies on request When to use it? When an axial bearing system with defined gliding partners is desired When extremely high wear resistance is required When a very low coefficient of friction is desired When not to use it? When an additional angle compensation is required igubal® axial bearing When little mounting space is available iglidur® J When only sporadic movements are present iglidur® G Y = wear [μm/km] Figure 36.1: The diagram shows the influence of load (p in MPa) and speed (v in m/s) on the wear of the axial bearing. Y= Coefficient of friction Figure 36.2: In the test with different speeds (v) and loads (p) the coefficients of friction of the bearing systems were determined (v in m/s, p in MPa). iglidur® JATM, metric d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

Polysorb Disk springs delivery program De [mm]: Di [mm]: disc springs are annulus discs stressable in the axial direction, which are turned over in the shape of a disc in the axial direction. disc springs provide a more favorable space usage than other spring types. They are particularly suitable for designs that demand a small spring deflection. + When not to use Polysorb Disk springs? For the implementation of specially flat load deflection curves that are possible with metal only with considerable complexity and expenditure (slotted versions). For compensation of axial clearance and manufacturing tolerances For vibration compensation For noise dampening When an antimagnetic material is required For electrical and thermal insulation When no corrosion problems should arise When lubrication is not necessary For low weight For low space requirement – When not to use polyserb disk springs? When constant spring forces are necessary over a wide temperature range When high spring forces are required The spring deflection of the disk spring is relatively small. Therefore a number of disk springs are combined in practice. Alternatively layered disk springs enhance the spring deflection in proportion to the number, whereby the overall spring force is as large as the force of the individual disk spring. To increase the force, the disk springs can be layered in parallel as a spring packet. Chemical resistance Polysorb disk springs are resistant to many chemicals. iglidur® A500 has a higher resistance than iglidur® J. Medium Resistance iglidur® J iglidur® A500 Alcohols + + Hydrocarbons + + Fats, oils without additives + + Fuels + + Diluted acids 0 to - + Strong acids - + Diluted bases + + Strong bases + to 0 + Humidity absorption The low humidity absorption allows them to be used in wet or humid environment. Polysorb® disk springs absorb humidity. Thereby their mechanical properties alter. In the worst application that can be thought of - extremely long application in water - Polysorb® disk springs still exhibit high spring force. iglidur® Standard environment saturated in water J 18 15 A500 24 23 Increased operating temperature Increased temperatures lead to the decline of stiffening in polymers. Polysorb® disk springs exhibit a maximum spring force of 8 N even at the maximum permitted temperature of 80° C. See figure for relationship of spring force to ambient temperature. Polysorb Disk springs long-term tests X = downward deflection [%] Y= spring force [N] A = JTEM-10 B = A500TEM-10 Figure 35.1: Spring force depending on the percentage of deflection measured in installation size 10 X= Ambient temperature [°C] Y= Maximum spring force [N] Figure 35.2: Influence of the ambient temperature on the spring force, measured on JTEM-10 Polysorb Disk springs delivery program De [mm]: Di [mm]: Dimensions according to DIN 2093

Request for a quote

IGUS® GMBH

Germany

iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: When to use iglidur® PEP plain bearings? When a low-priced plastic plain bearing system is required When freedom is required from shaft material and shaft surface For the protection of expensive and sensitive shafts For extraordinary wear resistance with rare and slow movements. For constantly low coefficients of friction When freedom from corrosion is desired When not to use them? For high surface speeds iglidur® J For high loads iglidur® G iglidur® Q For high temperatures iglidur® V400 iglidur® X iglidur® Z When low-clearance bearings are required iglidur® P iglidur® X Maintenance-free plain bearings usually distinguish themselves by their ability to glide free of lubricants without any further additional layer on the shaft. In these systems it is obvious that shaft materials are as important as the bushings. igus® blazes a new trail with an enclosed and maintenance-free plain bearing concept. iglidur® PEP is an entirely novel lubricant-free plastic plain bearing system with an inner and outer ring. Special feature: The running partner is determined by the inner ring and for the first time, the material and surface finish of the shaft are insignificant. Even thread, rust or scratches do not affect the long-term reliable function. By the specification of the gliding partner and extensive series of tests, the long-term behavior of the bearing system can be precisely forecast. With the PEP polymer plain bearing, the inner ring rotates with the shaft like in ball bearings Relative movements of the shaft to the bearing are dispensed with. This protects the shaft surface from wear and saves costs. Another plus point: Even the most sensitive or unusual materials for the rotating shaft can be used with these new polymer bearings. The PEP polymer bearings are thereby absolutely free from material-dependent corrosion. Wear resistance The wear test results are absolutely convincing with loads up to 5 N/mm². Here the PEP polymer bearings attain values that are virtually comparable with those of the most wear-resistant plastic-steel bearing systems. An exceedingly satisfying result when you consider the costs saved by dispensing with the otherwise essential surface treatment of the shaft. The constantly low friction-coefficient level is also an advantage for the user. As the glide partners are fixed by the defined system, their tribological data too are accurately predictable. The coefficients of friction of the lubricant-free bearing are not determined any more by the shaft materials or surface conditions. If necessary, the coefficients of friction can be further lowered by additional minimum lubrication. Detailed test information with a wide range of lubricants are available and can be had from igus® on request. iglidur® PEP bearings operate independent of the shaft material. iglidur® PEP bearings consists of an inner and outer bearing. X = Load [MPa] Y = Wear [μm/km] A = PEP B = Combination 1 C = Comb. 2 D = Comb. 3 E = Comb. 4 F = Comb. 5 G = Comb. 6 H = Comb. 7 A1 = Wear of the outer bearing B2 = Wear of the inner bearing Fig. 02: Wear tests of various material combinations, p = 0.75 MPa, v = 0.3 m/s X = Load [MPa] Y = Wear [μm/km] A = iglidur® J B = iglidur® PEP Fig. 03: Wear of the iglidur® PEP bearing dependent on the load, v = 0.3 m/s iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: Dimensions according to ISO 3547-1 and special dimensions

Request for a quote

IGUS® GMBH

Germany

iglidur® flange bearing d1 [mm]: With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. When to use iglidur® flange bearings? When you want a screw flanged bearing When a clip bearing solution is not satisfactory as a sheet metal feedthrough When there is a housing with very rough tolerances When the tight fit of a press-fit bearing is not sufficient as an axial securing When not to use them? When an additional angle compensation is required igubal® flange bearing When a screw connection is not possible iglidur® clip bearing When a large guide length is necessary iglidur® G General features With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. The design enables high loads with minimum demand on the precision of the housing. iglidur® maintenance-free flange bearings are available in four materials - iglidur® G, iglidur® J, iglidur® X and iglidur® A180. Thus, with this design, a very wide range of applications - from the universal bearing through the highest wear resistance or temperature resistance (up to +250°C) up to FDA-compliant bearing solutions - can be covered. Installation Dependent on the stressing capacities, various mounting types are used. For low radial loads, it is enough to mount the iglidur® flange bearing with just two screws on a surface. For higher radial loads, it is advisable to support the iglidur® flange bearing in a bore on the reinforced side in the load direction. Large tolerances are permitted for this bore, as it is only to additionally support the iglidur® flange bearing. In order to support still higher radial loads, the iglidur® flange bearing can be press-fitted with the longer side in an H tolerance bore. The additional screw connection secures the firm seating of the bearing in the housing. For the mounting of the iglidur® maintenance-free flange bearing, no special tools or devices are necessary. The alignment of the bearing in multiple mounted shafts is easily possible at the installation. Available materials: iglidur® G, iglidur® A180, iglidur® J and iglidur® X The mounting of the iglidur® flange bearing: Simple and safe iglidur® flange bearing d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

Special features Standard product range from stock radially and axially pre-tensioned plain bearings Completely free of clearance in unloaded state Material: iglidur® J Maintenance-free and calculable service life iglidur® JVSM, metric d1: iglidur® JVSI, inch d1 [inch]: iglidur® JVFM/JVFI Clearance-free pretensioned bearing, fully clearance-free in unloaded state, material: iglidur® J, maintenance-free and predictable service life iglidur® JVFM/JVFI Special features Standard product range from stock radially and axially pre-tensioned plain bearings Completely free of clearance in unloaded state Material: iglidur® J Maintenance-free and calculable service life When to use it? When a radial and/or axial pretension of bearings is desired When a derattling of the bearing in the unloaded state is required When a clearance-free feel is required When not to use it? When a bearing version with reduced clearance is needed Please contact us When the pretension has to withstand high radial forces When absolute clearance-free feature is required at high loads iglidur® JVSM, metric d1: iglidur® JVSI, inch d1 [inch]: iglidur® JVFM/JVFI Clearance-free pretensioned bearing, fully clearance-free in unloaded state, material: iglidur® J, maintenance-free and predictable service life iglidur® JVFM/JVFI

Request for a quoteManufacturer/ Producer

Spicher Str. 1a

51147 Köln - Germany