FRIMO GROUP GMBH - HIGH TECH AND HIGH PASSION

Germany

Multi-Category

FRIMO GROUP GMBH

Germany

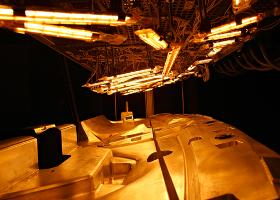

A concept for higher productivity FRIMO VarioForm inline and rotary table thermoforming machines are primarily used in the automotive industry and are ideally suited for forming a wide range of films and sheet materials.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for high quantities In vacuum laminating, plastic films such as TPO, TEPEO2 ® and PVC are heated and vacuumed to plastic substrate components, resulting in lamination. The adhesive applied to the substrate or decor material is activated, causing the two parts to bond. Vacuum laminating's special feature is that is can be combined with IMG (In-Mold Graining) in a single process. FRIMO offers this innovative and attractive technology with extensive market references.

Request for a quote

FRIMO GROUP GMBH

Germany

For sophisticated decorative materials Press laminating is mainly used to process materials that are unsuitable for vacuum processes, such as textiles, materials with and without foam backings or non-stretchable cover materials like leather or Alcantara. Processing these materials requires high quality tooling and machinery to ensure the quality of the grain, the soft touch and the color remain intact. The decorative element and the substrate are usually laminated together by being pressed between two hard instruments. Precise decor positioning and tool arrangements ensure optimal laminating conditions. Other forms of laminating include leather laminating and membrane laminating, which combines press laminating, edge folding, trimming.

Request for a quote

FRIMO GROUP GMBH

Germany

Leading the market Leather laminating is found mainly in the automotive industry. High quality vehicle interiors are characterized by a sophisticated design made of perfectly processed and adapted materials. Leather surfaces are no longer exclusively reserved for premium vehicles; they are also becoming increasingly used in high volume and mid-priced vehicle interiors. As a natural material, leather presents tough processing challenges. Variations, quality/quantity requirements and numerous project-specific parameters demand smart manufacturing solutions that can only be produced with extensive experience and in-depth technology and process expertise. FRIMO's tooling and equipment technology in leather processing leads the market. Along with leather laminating come leather back-foaming and leather scoring for hidden airbags.

Request for a quote

FRIMO GROUP GMBH

Germany

Adhesive-free equipment Bonding with the substrate component is carried out without adhesive. These processes are particularly useful for back-injected or back-pressed components, where the decorative material needs to cover component edges.

Request for a quote

FRIMO GROUP GMBH

Germany

Adhesive-based equipment The adhesive-based edge folding process differs depending on which adhesive is used. Some adhesives need to be activated and others do not.

Request for a quote

FRIMO GROUP GMBH

Germany

Fexible and available at any time FRIMO's ultrasonic standard components can be delivered quickly and used in all common system types or integrated into complex manufacturing lines. During ultrasonic welding/riveting, ultrasonic vibrations (20-30-40 kHz) are generated in the joining surfaces of the thermoplastic components. FRIMO generators, converters, and sonotrodes allow a particularly quick weld (within seconds). The processes can be monitored electronically, and the option of hand welding provides simple emergency strategies.

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

GEMONE

Belgium

Sapphire is a fleet management solution for the material handling industry. With automated OSHA-compliant checklists, real-time impact reporting, and PIN/RFID access control, Sapphire ensures safety compliance and minimises incidents. Its session and hours meters reporting features provide valuable insights into operator efficiency, aiding and optimising fleet composition. License management prevents unlicensed machine use. Supported by a robust cloud platform, Sapphire offers real-time reporting, transforming your warehouse into a safer and more efficient space.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free