FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Manufacturer/ Producer

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The high-speed servo-hydraulic control of the mill screwdown closes the loop: The thickness values measured precise to the micrometre form the basis for quick and precise control. Vollmer offers solutions for all control concepts from simple feedback control through to complete mass flow control or Direct gap contol for rolling of wedge-shaped strip and in tandem mills. Vollmer supplies the complete control system – from the sensors through the control technology right up to the hydraulics and the cylinder – from a single source. For our customers that means having just one contact partner – in short: A one-stop solution.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

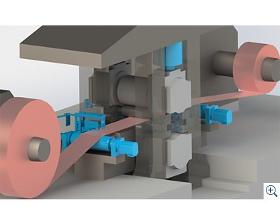

Proven for decades The contact gauges that measure the thickness / width of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible for up to 9 mm strip thickness / 32 mm strip width Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions. Optional the strip thickness gauge can be equipped with an additional strp width measurement unit.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Efficiency thanks to flat strip The use of flatness measurement alone without control already achieves a noticeable increase in productivity because strip breaks can be effectively prevented or the mill can be operated at the maximum possible speed for the particular unflatness. If the mill has the necessary adjusting elements, the Automatic Flatness Control (AFC) results in an effective improvement in quality. Control results of ± 4 I-units referred to the respective nominal curve are realistic. With our detailed know-how of the interplay between measurement, control and rolling mill we are on of the few manufacturers able to supply complete control systems for the strip shape – from the sensor through to the control of the adjusting elements From the pivoting of the rolls through to the combination of pivoting, bending, shifting of the intermediate rolls and zone cooling and far more – we have a command of the whole spectrum of shape control.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

In addition to the strip speed, VRecoS also records up to three further tracks, such as the rolling force or the strip thickness at the ingoing and outgoing ends of the mill. The measurement protocols can be stored, printed out and distributed by e-mail. The measured values are recorded as a function of length. The recording frequency can be set with a scanning rate of 2 ms. Random lengths of strip at the leading and trailing ends (drop-off) can be suppressed, even subsequently. The signals are recorded using a data collector belonging to the scope of supply. Its electronics with input and output modules is designed for installation in switch cabinets or desks in interference-proof 24 Volt top-hat (DIN) rail technology. It transmits the data via a network cable to the Windows recording computer which can be supplied by Vollmer or by the customer.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible from 0.01 to 24 mm Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions for thicknesses from 0.01 to 24 mm. Precise even on wavy strip With a measuring precision of down to one micrometre per millimetre of strip thickness, they meet the demands of modern rolling mills. Contact gauges adapt to the strip passage and follow any waviness of the material.

Request for a quoteManufacturer/ Producer

Verbandsstraße 60 b

58093 Hagen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssories use for machines.

Request for a quote

QUELLTECH GMBH

Germany

Laser Scanner Solution: This task is a typical application of the high-resolution QuellTech 2D/3D Q5-880 Blue Laser Scanners. Two of these units are placed at the left and at the right of the measuring objects, at a defined inclination angle. Blue laser light in this case is a prerequisite, as the cast parts are red-hot, hence emitting in the red spectral range. Additionally, the client was in need of a software solution for the project, so a 3D point cloud processing application was implemented, performing inline and evaluating width, height and angle results. QuellTech customer is able to inspect continuously the product quality, simultaneously avoiding scrap. He uses the same system for more than 10 different types of castings. Errors caused by manual inspection are considerably reduced, and safety for personnel is enhanced.

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer you Plane Mirrors (general, λ/1 and λ/4), for use within 3D Mapping Applications in a range of materials such as Soda-lime float glass, white float glass, and BK7 glass. Plane mirrors also known as front surface mirrors or first surface mirrors are used within 3D Mapping Applications. As stock we hold a number of general purpose, λ/1 and λ/4 with a range of up to 6 types of coatings such as Enhanced Aluminium, Ali/SiO2 and Ali/Mgf2. Our general purpose grade mirrors are made from good quality float glass and generally available in thicknesses of 1mm, 3mm and 6mm as standard. How our mirrors are used within 3D Mapping, is they are used as a sender and receiver of a laser beam that will take a reading of a specific surface, and from that reading it can create a 3D map of the surface that is has read. FOR MORE INFORMATION READ THE PDF..

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free