ETH MESSTECHNIK GMBH

Germany

Manufacturer/ Producer

ETH MESSTECHNIK GMBH

Germany

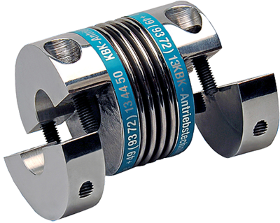

Metal Bellows Coupling with split hubs Backlash-free metal bellows coupling with split hubs For shaft diameters from 10 – 80 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with split hubs Backlash-free metal bellows coupling with compact split hubs For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling Leightweight ~ space saving ~ fast assembly / disassembly Torque range: 18 – 500 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling axial pluggable Backlash-free metal bellows coupling as axial pluggable execution Easy assembly / disassembly by simply plugging / pulling the coupling parts High tensile aluminum and special coatings ensure a durable solution at low mass / inertia For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 500 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Backlash-free angularly aligned transmission optimum compensation of misalignment very high torsion spring stiffness minimum restoring forces vibration damping ideal for measuring applications design with nickel bellows and screw hubs

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Backlash-free angularly aligned transmission optimum compensation of misalignment very high torsion spring stiffness minimum restoring forces vibration damping ideal for measuring applications design with nickel bellows and clamping hubs

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Mobile Mobile friction measurement for gear optimization 5 Nm or 30 U/min With the DPFR-036, changes in the design can be measured directly on the product. Even the smallest improvements can be identified. The area of application of this test facility is extremely diverse and can be easily implemented for other applications. The mobile design enables tests to be carried out under different temperatures and climatic conditions. Special features constant test speed independent of load selectable direction of rotation and speed Additional storage to eliminate lateral forces Acquisition of torque and angle of rotation Graphical recording of the test procedure Simultaneous viewing of up to 20 variable test sequences from the database in color Option OK and NOK signal lights

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Friction measurement on gear with cam recording with service case In order to reduce the frictional torque in a gearbox from the automotive industry, a measuring device that accompanies the development is required. With the DPFR-027, changes in the design can be measured directly on the product. This means that even the smallest improvements can be determined. The field of application of this test device is extremely diverse and can be easily converted to other applications. Thanks to the mobile design, tests can be carried out under different temperatures and climatic conditions. hand-held drive unit compact slim design constant load-independent test speed selectable direction of rotation and speed additional storage to eliminate lateral forces Acquisition of torque and angle of rotation Graphic recording of the test sequence Storage of the test results in Excel

Request for a quote

ETH MESSTECHNIK GMBH

Germany

DPFR-004 Customized Solution for friction measurement of transmission A hand-held enclosure with integrated torque transducer, start buttons and 1 display for torque andf speed. Is used to the friction torque of tapered roller bearing set or monitor. portable Safety circuit by two-hand operation Constant load independent test speed

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Customized Solution Hand-held device with integrated torque transducer. Direct channel selection of filed test programs. Drive of the transmission is achieved to the predetermined moment of friction during the assembly. Subsequent break-in period and subsequent Reibwertprüfung with threshold monitoring, visual evaluation and documentation. Direct channel selection of filed test programs Safety circuit by two-hand operation Constant load independent test speed either vertically or horizontally about Balancer

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Customized Solution The mobile testing device may be mounted directly on the wheel nuts on any wheel on the car. The height and tilt adjustment allows optimal orientation at the wheel. Additionally, it is still supported by three proximity sensors. The evaluation and control of the testing device accepts a laptop. For easy transport, the device can be disassembled in a few steps. Curve recording and analysis via notebook. The complete unit is height adjustable via a scissors system. This can also be adapted to different shaft height.

Request for a quote