BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Manufacturer/ Producer

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For increased system efficiency and reduced fuel consumption of up to 2% — Prewarming of the combustion air takes over a small portion of the thermal output of the burner — Lower investment costs in comparison with conventional solutions, low amortisation time — Lower maintenance and servicing costs

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Blow-down, expansion and cooling module for cooling blow-down water to the permissible temperature — Fast and easy assembly, requires just a small number of connections before the Blow-down, expansion and cooling module can be used — Rigorous compliance with official requirements thanks to automatic operation

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the cooling of blow-down water and the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Rigorous compliance with official requirements thanks to automatic operation — Fast and easy assembly, requires just a small number of connections before it can be used

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the convenient operation of steam boilers up to 4,000 kg/h of steam — Appealing price-performance ratio for steam boilers up to 4,000 kg/h of steam — Colour touch display for easy operation and clear visualisation of operating status — Flexible installation and small space requirement: installed on the boiler at the factory or loose control cabinet for wall mounting — Power electronics for fuel supply, feed water pump, blow-down and desalting — Optional: fully automated and conductivity-controlled blow-down and desalting

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Comprehensive monitoring and alarm functions enable you to react quickly as needed to ensure the reliable availability of heating energy and process heat. — Convenient remote monitoring of your boiler system and access to all important operating parameters — Simply integrate the remote technology for connection via Internet or a company network — Fast and cost-efficient online support from Bosch experts on request — Safety first: Certified, multilevel security concept for your remote access — Automatic alarm notification by text message or e-mail as an option so you can react quickly when needed

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

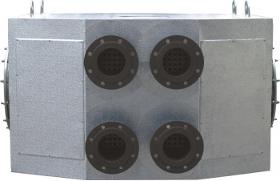

— For distributing the steam mass flow to the relevant consumers — Reduction in network loss due to centralised distribution in systems with complex consumer structures — Savings thanks to centralised operation and maintenance Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The steam boiler CSBs low emissions already comply with future requirements of the MCP Directive (EU) 2015/2193. — Large output range from 300 to 23,600 kg/h for pressures ranging between 0.5 and 16 bar — High efficiency thanks to the integrated economiser and helical heat exchanger pipes — Versatile design for use with different fuel types and as a multi-fuel firing unit (oil, natural gas, bio gas, up to 20 % hydrogen) — Compliant with even strict emission levels when used in combination with our burners and controls — Telescopic reversing chamber makes cleaning, maintenance and inspection simple — Easy to operate with CSC boiler control (up to 4,000 kg/h) and boiler control

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Modular complete solution with cost advantage, for all single-flame-tube hot water and heating boilers — Intelligent sequence control for up to four boilers — Intuitive operation via colour touch display and function keys for quick access — Pre-configured and completely wired for quick commissioning — Integrated power supply in the compact control cabinet, e.g. for burner and pumps — Compatible with all common automation system protocols — Optional remote access via MEC Remote for maximum availability

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Modernisation pays off: The average service life of boiler systems that are used for industrial purposes is between 20 and 40 years. Many measures which previously were not possible or financially justifiable pay off nowadays after a very short period of time. Five good reasons to modernise your energy generating system: — Reduce operating costs — Security of supply — Structural adjustments — Sustainability — Maintaining legal conformity

Request for a quoteManufacturer/ Producer

Nuernberger Strasse 73

91710 Gunzenhausen - Germany