- europages

- >

- Springs

- >

- ACE STOSSDÄMPFER GMBH

- >

- products

ACE STOSSDÄMPFER GMBH

Germany

Manufacturer/ Producer

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating or Optimized Characteristic Energy capacity - Nm/cycle Stroke 48.6 mm Effective emergency stop: The ACE safety shock absorbers from the SCS33 to SCS64 product family are based on the innovative technology of the successful industrial shock absorbers from the MAGNUM-Series. They are also maintenance-free and ready-to-install. Due to the optimised characteristic curve for the respective application, the energy absorption of these hydraulic machine elements can be increased to more than twice the level of the MAGNUM model of ACE industrial shock absorber per stroke. Users benefit from a service life of up to 1,000 full load emergency cycles with a very good price-performance ratio. Their compact design in sizes M33x1.5 to M64x2 makes them easy to integrate into current applications.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

High Rack Damper, Optimized Characteristic Energy capacity 3,600 Nm/cycle Stroke 50 mm Intelligent protective measure: The safety shock absorbers from the SDH38 to SDH63 series are also designed for emergency-stop applications. Strokes of up to 1,200 mm are possible with these maintenance-free and ready-to-install dampers. Low support forces result due to the large strokes. The characteristic curve or damping characteristics of all safety shock absorbers from ACE is individually adjusted to the respective application, specific to the customer. The metering ori?ces for the respective application are specially calculated and produced. These tailor-made machine elements are the ideal protection because they are less expensive than industrial shock absorbers and are effective with up to 1,000 maximum full load emergency cycles possible.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

High Rack Damper, Optimized Characteristic Energy capacity 14,500 Nm/cycle Stroke 100 mm Intelligent protective measure: The safety shock absorbers from the SDH38 to SDH63 series are also designed for emergency-stop applications. Strokes of up to 1,200 mm are possible with these maintenance-free and ready-to-install dampers. Low support forces result due to the large strokes. The characteristic curve or damping characteristics of all safety shock absorbers from ACE is individually adjusted to the respective application, specific to the customer. The metering ori?ces for the respective application are specially calculated and produced. These tailor-made machine elements are the ideal protection because they are less expensive than industrial shock absorbers and are effective with up to 1,000 maximum full load emergency cycles possible.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Crane Installations Energy capacity 450 Nm/cycle Stroke max. 62 mm For even more protection: The profile dampers from the TC range of the ACE TUBUS-Series can also be used as safety dampers. These maintenance-free, ready-to-install damping elements made of co-polyester elastomer have been specially developed for use in crane systems and fulfil the international industry standards OSHA and CMAA. In the special TC-S design, managed to achieve the spring rate required for crane systems with the unique dual concept. Whether TC-S or TC, this range of models represents a cost-effective solution with high energy absorption for energy management systems. The very small and light design of Ø 64 mm to Ø 176 mm progressively covers energy absorption within a range of 450 Nm to 17,810 Nm.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

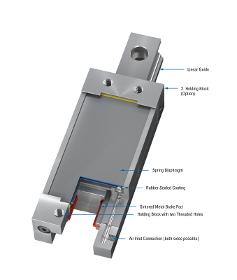

Process Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family PLK clamping elements are more compact than the Series PL components. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and space-saving. Thanks to the patented spring steel plate system, the LOCKED-Family PLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. LOCKED PLK achieve 100 % clamping force due to the steel pads that are used, even on greased rails. The clamping elements represent the maximum holding forces. Whether in the 4 or 6 bar version, they are good for up to 1 million cycles.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

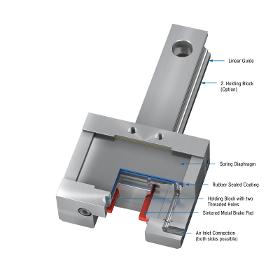

Safety Clamping for Rail Systems Holding force 540 N Always on the safe side: The safety clamping elements LOCKED SL clamp and brake directly on the clear area of guide rails on linear modules with forces of up to 10,000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profiles from all renowned manufacturers. Special brake pads made of low wear sintered metal are used for the additional emergency stop braking functions in the safety clamping elements LOCKED SL. The SL product family offers optimum static clamping with a service life up to 1 million cycles or up to 500 emergency braking operations. They also offer low system costs in comparison with hydraulic and electric solutions.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Safety Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family SLK clamping elements are more compact than the Series SL. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and safe. Thanks to the patented spring steel plate system, the product family SLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. Thanks to the sintered metal coatings and the clamping function in emergency stop (e.g. in case of a power failure), this range enables braking directly on the rail. All clamping elements offer the maximum holding and braking forces and achieve up to 1 million clamping cycles or up to a maximum of 500 emergency braking operations in the 4 and 6 bar version.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Rail Clamping for Z-Axes Holding force 1,500 N Innovative and BG certified: The pneumatic clamping elements LOCKED LZ-P have been specially designed for safe, reliable clamping on the vertical or Z-axes. The wedge principle makes sure that the gravity loaded axis does not drop. The brake wedges are pushed on both sides against the flat parallel surfaces of the guide rail in case of a loss of pressure. Initially developed for Bosch Rexroth rails in sizes 15 and 25 mm, a test certificate from the trade association was awarded after extensive tests on these clamping elements. Further certifications from other rail manufacturers and sizes are prepared and can be implemented within the shortest time. Users achieve holding forces of up to 2,500 N.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Pneumatic Rod Clamping, Compact Holding force 700 N Holding torque 7 Nm Compact and safe: when space becomes restricted, the compact LOCKED PRK clamping elements come into their own. As pneumatic rod clamping with low heights of 28 to 34 mm, they provide clamping forces of up to 5,000 N. Clamping is carried out by a diaphragm spring-plate system and is released when compressed air is applied. Clamping elements from the LOCKED PRK product family absorb the forces on rods with diameters between 20 and 40 mm both axially and rotationally. The function makes them suitable for use as static clamping without pressure, because the failure or drop of pneumatic pressure triggers immediate clamping. High clamping forces with low system costs compared with hydraulic and electric solutions make these clamping elements particularly interesting.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

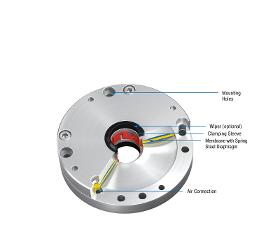

Pneumatic Rotational Clamping Holding torque 76 Nm Direct clamping on the shaft: Rotation motions are prevented by the ACE models LOCKED R. Their clamping elements are available for shaft diameters of 50 to 340 mm and ensure maximum holding forces. The clamp is immediately applied by the diaphragm and spring-plate system when pressure is lost. Pneumatic quick-switch valves reduce the reaction times. The costs are low in comparison with hydraulic clamping systems. Their performance is, however, achieved or exceeded despite the compact and easy to assemble design. Special versions for YRT bearings as well as active clamping elements are additionally available. ACE recommends the use of the optional shaft flange as wear protection. The clamping force can be increased considerably by the use of the additional air function.

Request for a quoteManufacturer/ Producer

Albert-Einstein-Strasse 15

40764 Langenfeld (rheinland) - Germany