- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machinery-manufacturer

Results for

Machinery-manufacturer - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel cnc machining.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK has been a successful innovator and manufacturer of ball guides for linear motion technology for decades. SCHOCK ball guides are known for their precision, high load capacities, and long lifespan. Key features of SCHOCK ball guides include: Excellent running properties High operational reliability Long lifespan without maintenance Custom connection options Based on individual customer requirements, we develop and manufacture ball guides as runner guides, partial extension, full extension, or over-extension. In collaborative project planning with our customers, we define the product requirements for the ball guides. Our customers benefit from a wide selection of rail profiles, mounting systems, comfort features, and high-quality surface finishes, such as SCHOCK powder coating. We supply powder-coated ball guides in any desired RAL color, offering you unique design possibilities.

Request for a quote

SCHOCK GROUP

Germany

We manufacture complex assemblies for our customers, incorporating process-controlled assembly processing along with comprehensive supply chain management. We offer our customers a comprehensive procurement, manufacturing, and delivery service of the highest quality. You benefit from our process-controlled assembly processing through the production and delivery of complex assemblies. Our service offerings include, among others: Assembly of kinematic components Manufacturing of complex assemblies Stable supply chains from European production Centralized logistics Complete value creation from a single source

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

SCHOCK GROUP

Germany

Cold-drawn heavy-duty rails offer exceptionally high load-bearing capacity and stiffness. In our eShop, you can find partial extensions, full extensions, and over-extensions up to 3000 mm in length and with a load capacity of up to 2400 kg. Cold-drawn heavy-duty telescopic extension rails are suitable for extreme loads and stresses. The precision-machined ball tracks ensure accuracy and provide excellent shock and vibration resistance. Therefore, these telescopic rail models are well-suited for demanding tasks in machinery manufacturing, the military sector, special vehicle construction, and heavy-duty shelving. Due to their extreme strength, these telescopic rails are particularly resistant to lateral forces, making them an excellent choice for dynamic and motorized applications, especially at very large lengths. They can also be used at high temperatures since no plastic parts are used.

Request for a quote

SCHOCK GROUP

Germany

With SCHOCK Powder Coating, we achieve high-performance and visually appealing product surfaces with long-term corrosion protection and individual color customization. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production. Our coating facility is located at the central logistics hub of the SCHOCK Group in DE-72296 Schopfloch. This ensures our customers receive punctual, reliable, and cost-effective deliveries. Electrostatic powder coating relies on the attraction between parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are needed, powder coating is indispensable. These properties have led industries such as equipment manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures and furniture manufacturing, as well as the automotive industry to largely transition from wet paint

Request for a quote

IGUS® GMBH

Germany

Other information IF -Design Award for Triflex®-Design Torsional movements possible Other information Installation instructions Joining, separating and filling of the Triflex®. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. Triflex® 332.16 Inner height hi: 16 mm Inner width Bi: 16 mm Bending radii R: 38 - 100 mm Pitch: 13.3 mm E-Chain®. 332.32 Inner height hi: 32 mm Inner width Bi: 32 mm Bending radii R: 75 - 250 mm Pitch: 25 mm E-Chain®. 332.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 100 - 250 mm Pitch: 30 mm E-Chain®. 332.75 Inner height hi: 75 mm Inner width Bi: 75 mm Bending radii R: 140 - 300 mm Pitch: 36 mm E-Chain®. 352.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 10 - 250 mm Pitch: 30 mm E-Chain®, snap-open 333.16 Inner height hi: 16 mm Inner width Bi: 16 mm Bending radii R: 38 - 100 mm Pitch: 13.3 mm E-Chain®. 333.32 Inner height hi: 32 mm Inner width Bi: 32 mm Bending radii R: 75 - 250 mm Pitch: 25 mm E-Chain®. 333.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 100 - 250 mm Pitch: 30 mm E-Chain®. 333.75 Inner height hi: 75 mm Inner width Bi: 75 mm Bending radii R: 140 - 300 mm Pitch: 36 mm E-Chain®. 353.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 10 - 250 mm Pitch: 30 mm E-Chain®, snap-open This modular, rugged joint system is suitable for: Three-axis movements for machines of any type For dirt-filled environments High tensile strength Where rectangular shapes are requested Completely closed - reliable protection against dirt and chips Combination of different bending radii and axes Connection and separation possible at any chain Flanged mounting brackets or brackets, galvanized steel Snap-open Series 352 and 353 Combination of Series 353/333 possible Typical industrial sectors and applications Machine tools Robotics Material handling system Plastics industry Construction machinery Vehicle manufacturing Medical equipment IF -Design Award for Triflex®-Design Torsional movements possible

Request for a quote

IGUS® GMBH

Germany

Other information iF-Design Award for easy triflex® Design UL94-V2 classification Torsional movements possible Other information Installation instructions Join, separate and fill the easy triflex®. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. Triflex® E332.25 Inner height hi: 25 mm Inner width Bi: 25 mm Bending radii R: 48 - 200 mm Pitch: 14.5 mm e-chain® E332.32 Inner height hi: 32 mm Inner width Bi: 32 mm Bending radii R: 75 - 250 mm Pitch: 25 mm e-chain® E332.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 100 - 250 mm Pitch: 30 mm e-chain®. E332.75 Inner height hi: 75 mm Inner width Bi: 75 mm Bending radii R: 140 - 300 mm Pitch: 36 mm e-chain® E333.25 Inner height hi: 25 mm Inner width Bi: 25 mm Bending radii R: 48 - 200 mm Pitch: 14.5 mm e-chain® E333.32 Inner height hi: 32 mm Inner width Bi: 32 mm Bending radii R: 75 - 250 mm Pitch: 25 mm e-chain® E333.50 Inner height hi: 50 mm Inner width Bi: 50 mm Bending radii R: 100 - 250 mm Pitch: 30 mm e-chain®. E333.75 Inner height hi: 75 mm Inner width Bi: 75 mm Bending radii R: 140 - 300 mm Pitch: 36 mm e-chain® This modular joint system is especially suited for: Three-axis movements of machines For simple robotic applications Quick installation of cables with "easy" system Simple filling from both sides Where rectangular shapes are required Combination of different bending radii and moving directions Shortening or lengthening possible at "any point" KMA mounting brackets with integrated strain relief Typical industrial sectors and applications Machine tools Robotics Handling equipment Material handling system Plastics industry Construction machinery Vehicle manufacturing General mechanical engineering Medical Equipment Office furniture iF-Design Award for easy triflex® Design UL94-V2 classification Torsional movements possible

Request for a quote

KEBA FASTENINGS

Germany

PRODUCTION CAPABILITIES KEBA Fastenings’ processing capacity for Turned-Parts comprised of steel, brass, aluminum, and stainless steel bars ranges between Ø 1mm to Ø 60mm via CNC Auto Lathe, Index, and Sliding Automat machinery. The manufacturing technology and team capabilities allow for custom made parts according to customer-specific drawings. SURFACE TREATMENT • Browning • Anodised • KTL • Zinc - Lamella • Galvanized (blue, yellow, black) • Zinc - Iron • Zinc - Nickle Powder • Phosphating • Chrome • Copper

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Round belts are used for conveying in the textile, wood-working, ceramic, packaging and chemical industries.Siegling Transilon round belts serve as efficient drive elements in both precision tool and machinery manufacturing. Siegling Round belts have also proven their reliability as drive elements for live roller conveyor repeatedly. Their great flexibility and elasticity make any turn possible.

Request for a quote

SCHOLPP GMBH

Germany

Complete installation: services for machinery manufacturers. One part of our services is performing the same installation processes again and again, or complete installations of similar machinery by one manufacturer. To maximize speed, efficiency and quality, we familiarize one or several teams with the specific characteristics of your machinery. This means we are ideally placed to support your staff all the way from disassembly, through transport, to ensuring production readiness. Depending on the task in hand, we assemble interdisciplinary teams with specialists from a variety of fields, including mechanical engineering, mechatronics, electronics, and electrical engineering. And we carefully select equipment, with the best interests of your machines in mind. We guarantee that your machinery will be lifted at the correct points and be up and running as soon as possible. SCHOLPP can train one or more teams on the specific characteristics of your machinery on request.

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

The new Deichman Main Library, which opened in 2020, stands right beside the Norwegian Opera House in Oslo. Now complete, the library is a paragon of energy efficiency and low greenhouse gas emissions. We are delighted to have contributed towards the success of this project. Some of the extralarge, solid window frontage profiles on the sixstorey building were manufactured using modern machinery at TechnoComposites Domine GmbH. At approx. 0.5 metres thick and featuring several hollow chambers, these façade element profiles are clearly visible on the building.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This force measurement chain was developed for applications where a low cost solution is more important than achieving high levels of accuracy. The sensors strain gauge technology allows the measurement of static and dynamic forces. The load cell is also designed for applications that provide only little space due to its compact design. These properties, together with the sensors dust protection, make the measuring chain suitable for a wide range of applications, such as Industrial manufacture Manufacture of customized machinery Geological investigations Motor vehicle engineering Commercial agriculture Bridge building The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor. The domed form, however, minimizes the effect of a force that is not exactly axial.

Request for a quote

HEINZE & STRENG GMBH

Germany

For our carbon fibre bows, we offer wire guide elements for custom equipping made of: ceramic- carbide- tempered steel and special roller designs

Request for a quote

MIXACO MASCHINENBAU

Germany

The MIXACO container mixer Multitool™ is ideal for the careful mixing of temperature-sensitive materials. An innovative mixing concept with new tools and a special process enables mixing without temperature increase. The MIXACO Multitool™ is a container mixer with numerous benefits for internal logistics and production workflows, as it can be seamlessly integrated in work processes. All Benefits at a Glance * Minimal product heating * Optimum homogenization * Adjustable comminution rate * No fusion or adhesion of material * Reduced cleaning time * User-friendly, ergonomically optimized cleaning in preconfigured cleaning position * Material transport in mixing container for greater logistical efficiency * High flexibility * Wide range of tool and motor combinations enable use in many different mixing tasks * Low energy consumption

Request for a quote

SHINING 3D TECHNOLOGY GMBH

Germany

As the blue laser handheld 3D scanner of the FreeScan series, FreeScan UE inherits the iconic features of "high accuracy" and "high precision". At the same time ergonomic and lightweight equipment design, make it easier to hold and operate, providing metrologygrade, highaccuracy inspection solutions for the automotive, transportation, aerospace industry, moulding inspection, energy generation, machinery manufacturing and etc.Metrologyclass high accuracy Accuracy up to 0.02mm, Volumetric accuracy 0.02mm+0.04mm/m.Stability of repetitive measurement When measuring the same workpiece repeatedly, FreeScan UE delivers consistent results, proving stability and reliability.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA NONWOVENS GMBH

Germany

High packaging quality is always the crucial factor. The OPTIMA HS/OS3 bag packer and packaging provides the right packaging to best showcase logos and printing at the point of sales. The adjustable high compression further enhances quality and brings with it a number of advantages in logistics. Optima Nonwovens packaging machines are flexible: The machines can be adjusted quickly and easily for a large range of formats, format sets and modules. Fully automatic high-speed stacker for baby diapers Quick and easy change-over Quality gate Modular machine structure Designed for easy maintenance

OPTIMA NONWOVENS GMBH

Germany

For packaging baby diapers and training pants, high performance and reduced package dimensions are in demand. Adapted to these requirements, the OPTIMA LS/OS3 packaging machine offers maximum flexibility and ideal product protection. Modular machine structure Taylor made solutions to match individual requirements Quick and easy change-over Premade polyethylene bags on wickets User friendly touch screen Designed for easy maintenance

OPTIMA NONWOVENS GMBH

Germany

For packaging light incontinence products, high performance and a huge variety of packages are in demand. Adapted to these requirements, the OPTIMA HS/OSI bag packer and packaging machine offers maximum flexibility and ideal product protection. Stackers from Optima Nonwovens can synchronously accommodate the infeed of incontinence products from manufacturing machines. The products are counted by the stacker and arranged in pre-defined layouts. As the link to the packaging machine, the stacker quickly and gently supplies the products to the further packaging process. The OPTIMA OSI bagger delivers high outputs and can accommodate an extremely broad range of formats and larger packages. Modular machine structure Quick and easy change-over Multiple product rows possible Tilting cassette Premade polyethylene bags on wickets

OPTIMA NONWOVENS GMBH

Germany

The modular design of the OPTIMA PAKSIS D5 allows customization for individual packaging needs. The stacker, fully equipped with two manual filling stations, is often used at the beginning of a diaper production. As the need for automatization rises, the base bagger can be added from the beginning or at a later point in time. Designed and manufactured in co-operation with Fameccanica Data S.p.A.Modular machine structure Sturdy design

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OSR bag packer and packaging machine can handle tissue products of all types, supporting all required roll product formations of kitchen towels and bathroom tissue in one or multiple layers. Optima Nonwovens machines and modules are designed to meet your specific requirements. Bathroom tissue and kitchen towel rolls can be packed on Optima equipment in pre-made polyethylene bags. This is how Optima Nonwovens has maintained its status as a leader in the industry. Full servo technology Modular machine structure Taylor made solutions to match individual requirements Small foot print Quick and easy change-over Single and double layer packages possible Premade polyethylene bags on wickets Point of sale packages Carry-handle possible Perforation for easy bag opening possible

OPTIMA NONWOVENS GMBH

Germany

Whether compressed large packages or sales packages with excellent visual and haptic quality, this segment is characterized by strongly varying requirements. Modular packaging machines such as the OPTIMA LS/OS8 can meet all these needs at the same time. Industry-leading outputs combined with very high machine reliability ensure productivity, while additional quality control functions for both, process and product, further sets these units apart from the competition. The OPTIMA OS8 bagger can be ideally combined with the OPTIMA LS stacker. Not only can an unrivalled range of formats be flexibly processed with this system; the integrated modules and additional (control) functions open up a new dimension of packaging process design. Modular machine structure Multiple product rows possible Stack turning possibility Quick and easy change-over Premade polyethylene bags on wickets

OPTIMA NONWOVENS GMBH

Germany

Fully integrated counting, stacking, and packing machine for maximum process control and operability. The OPTIMA PAKSIS D7 assures quick and easy installation and start up. Full servo technology for all operating units to provide maximum flexibility for diverse packaging requirements as well as quick changeovers. The packaging machine OPTIMA PAKSIS D7 offers a sturdy design and easy accessibility to the process units. All parts in contact with the product are designed in stainless steel or surface coated. Designed and manufactured in co-operation with Fameccanica Data S.p.A. Further information is also available at PAKSIS D7 - Breakthrough packaging systemsOptimized process control Full servo technology Quick and easy change-over Sturdy design

OPTIMA NONWOVENS GMBH

Germany

Fully integrated counting, stacking, and packing machine for maximum process control and operability. The Packaging Machine OPTIMA PAKSIS A6 assures quick and easy installation and start up. Full servo technology for all operating units to provide maximum flexibility for diverse packaging requirements as well as quick change overs. The OPTIMA PAKSIS A6 offers a sturdy design and easy accessibility to the process units. All parts in contact with the product are designed in stainless steel or surface coated. Designed and manufactured in co-operation with Fameccanica Data S.p.A. Further information is also available at PAKSIS A6 - Breakthrough packaging systemsOptimized process control Full servo technology Quick and easy change-over Sturdy design

OPTIMA NONWOVENS GMBH

Germany

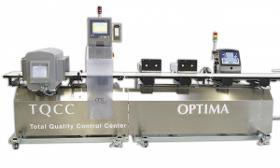

Metal detection based on measurement of magnetic permeability Check-weighing process with industrial load cells Rejection pushers mounted on a separated frame to avoid any vibrations 5 separate servo driven belts Interface between TQCC and bagger included One HMI for metal detector, check-weigher and rejection Modular design for easy service

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OS5 bag packer and packaging machine offers a new method for packaging tissue paper into either polyethylene bags or polyethylene film with the integration of reasonable product compression during the packaging process. The final packed product comes out as a nice, tight, compact package which is easy to palletize. Carton boxes for the secondary packaging are not needed anymore. The press capacity allows perfectly adapted product compression without any quality deficits. Due to the tight and compact film package, the number of truck loads required for transporting only the packaging material is significantly reduced as well as for the transport of the final package. Altogether, the new packaging method gives a high potential in cost saving on packaging material warehouse storage, shelf space and logisitcs and it is environtmentally friendly. Quick and easy change-over Premade polyethylene bags on wickets Carry-handle possible

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA WWM loads pre-packed wet wipes into PE bags. The machine concept is based on the LBV series which can be found in most of the countries around the globe. Packaging of paper hygienic products asks for minimum volumes at maximum speeds. From standard machines to high-performance packaging lines, machines from Optima Nonwovens are modular in construction and allowing to implement your special requirements. Secondary packaging of pre-packed wet wipes Handling of up to 4 rows possible Quick and easy change-over Cross direction feeding of pre-packed wet wipes

OPTIMA NONWOVENS GMBH

Germany

For packaging panty liners or sanitary napkins (regular or ultra thin), either flat or folded and wrapped, high performance and a huge variety of packages are in demand. Adapted to these requirements, only the best machinery offers maximum flexibility and ideal product protection. Fully automated machinery by the OPTIMA ON3/OS2 bag packer and packaging machine delivers the optimum process quality to deliver lowest cost per pack to our customers. Modular machine structure Multiple product rows possible Quick and easy change-over Premade polyethylene bags on wickets Tilting cassette

Results for

Machinery-manufacturer - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Paper and cardboard manufacturing - machinery and equipment (13)

- Paper - manufacturing machinery (5)

- Building materials, manufacture - machinery and equipment (3)

- Anti-corrosion coatings (2)

- Ceramic manufacturing - machinery and equipment (1)

- Recycling - machines and installations (1)

- Air filtration equipment (1)

- Buildings, modular (1)

- Coatings, insulating (1)

- Fasteners, metal (1)

- Light-emitting diode LED (1)

- Machinery and equipment, used and reconditioned (1)

- Rails and sliding frames (1)

- Sensors (1)

- Transmission belts (1)