- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- zone valves

Results for

Zone valves - Import export

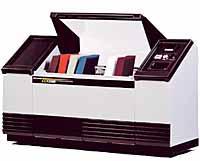

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Basic cyclic tests are used to qualify a coating or material for a specific end use on a pass-fail basis, or determine the probability of corrosion of a specific material. Applications include: Aerospace, Appliances, Automotive, Government, Marine Craft, Paints/Coatings, Research, and Telecommunications. Reinforced fiberglass cabinet, exposure lined with gel coat Solution reservoir - 35 gal (132L) Clear cover with dual magnetic Santoprene gasket (BCX9000 comes with opaque Polypropylene cover) Peaked cover prevents dripping of condensate onto sampl Exposure zone heated by titanium rod heater Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 131 °F (55 °C) - Hight temperature option up to 160 °F (71 °C) Omni-Fog Dispersion Tower or Omni-Fog II Dispersion System, fully adjustable. Built-in support ledges, front and back Wet Bottom Drain Assembly; heated, with auto fill for higher and more uniform humidity (n/a BCX11000) Air-assisted Cover Lifters on BCX9000 and BCX11000 Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) BCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 1.93 x 0.9 x 1.4 m BCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 2.46 x 0.9 x 1.4 m BCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 2.46 x 1.1 x 1.4 m BCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 2.69 x 1.32 x 2.16 m BCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 2.82 x 2.29 x 1.83 m Combination exhaust condenser and wet bottom drain assembly Recorder, 2-pen circular chart, digital display, 7 day, wet bulb and dry bulb Recorder, 6 channel strip chart; 4 temperature probes and air pressure Modem for remote trouble shooting Solution spray, two-nozzle External condensate collection package High voltage kit (over 460 VAC) Gas injection system for SO 2, CO 2, NO x High capacity oil & water extractor Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Air-actuated Cover; required for tests specifying ambient conditions Solution Spray; multiple nozzles (8, 12 or 16) with individual shut-off valves CE, UL CSA Conformance certifica High Temperature System, to operate BCX up to 71ºC / 160ºF BCX2000/BCX3000/BCX4000/BCX9000/BCX11000 SO 2 Injection; for customer-supplied SO2, customer-supplied fume hood recommended Data Recording Software; PC based, sends data to customer's computer

TURKOGLU

Turkey

Body and Cover : GG-25 Cast Iron / Handwheel: GG-25 Cast Iron / Gasket: EPDM / O-ring: EPDM / Spindle: Stainless steel / Segment Gear : GGG-40.3 Ductile Iron. ** Connection Type: Flanged / Working Pressure :175-300 PSI / Working Temp.:-10ºC , + 120ºC / Working Test Pressure : 600 PSI *** OS&Y gate valve is developed to be used as the cut off and zone control valves in order to substitute supervisory switched butterfly valves in the fire security systems. Just to make them visible and traceable inside the systems, they are preferred to be used with post indicators instead of wheels. **** Application Areas: It can be use in every fire fighting systems, but it usually use in water tank and in front of the pumps.

Request for a quote

TURKOGLU

Turkey

Body and Cover : GG-25 Cast Iron / Handwheel: GG-25 Cast Iron / Gasket: EPDM / O-ring: EPDM / Spindle: Stainless steel / Segment Gear : GG-25 Cast Iron . ** Connection Type: Flanged / Working Pressure :175-300 PSI / Working Temp.:-10ºC , + 120ºC / Working Test Pressure : 600 PSI *** NRS gate valve is developed to be used as the cut off and zone control valves in order to substitute supervisory switched butterfly valves and OSY rising stem valves in the fire security systems. These valves are usually burried underground to prevent the risk of freeze. Just to make them visible and traceable inside the systems, they are preferred to be used with post indicators instead of wheels. **** Application Areas: In fire fighting systems, which is non-affected by freeze, than they are using under the soil.

Request for a quote

EUROPEM

Belgium

Handling of ATEX explosive gas mixtures Static ATEX zone 0 vapor extraction system upstream of an incinerator. Application: treatment of volatile organic components coming from loading operations of (petro) chemical products, tankstorage, tankcleaning, chemical processes … Zone 0 extraction : piping and valve train Zone 0 extraction up to inlet combustion chamber

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MECANUMERIC

France

This new 3 axis CNC machine range has been entirely modified in 2006. Completely covered, this equipment is in conformity with CE norms. Refer to the exemples of applications : Moulds and models EDM electrodes Bronze medal Telephone casing model MACHINING CENTER FOR 3D PRECISION ENGRAVING AND MOULDS , MODELS, ELECTRODES OR PUNCHES REALIZATION EQUIPMENT OPTIMIZED FOR THE MACHINING OF FOLLOWING MATERIALS: . Aluminium . Synthetic resins . Steel . Brass and copper alloys . Plastics and composites . Graphite AVAILABLE SIZE: Model X travel mm Y travel mm Z travel mm TR 75 520 750 325 TECHNOLOGY: . Kinematic unit with fixed table and mobile gantry. . Steel welded frame. . Steel welded mobile gantry . Vacuum table in aluminium profiles or composite . Holding of plates by vacuum generated either by lateral canal turbines or by vacuum claw pumps. Selection of zones with manual valves. . Motorisation by AC Brushless servomotors on the 4 axes (X1-X2-Y-Z), double driving on X axis. ....

Request for a quote

KONTAKT LLC

Ukraine

Gas pressure regulators RD-M are designed to reduce and automatically maintain the gas pressure “after itself” at the set value. Gas pressure regulators of the RD-M type are used at the facilities for main gas pipelines: Gas distribution stations, Gas purification and dehydration installations, Compressor stations, Gas fields. Distinctive features of the RD-M regulator: Hydrate formation in the “seat-valve” contact zone does not affect the regulator operation. Tightness at full closing of the valve. Smooth regulation characteristics due to the use of an oil compensator. High accuracy of maintaining the set pressure. High maintainability (possibility to repair wearing parts without removing the regulator body from the reduction line). Possibility to automate the reduction process. Upper setting limit, MPa/(bar)-1.2/(12) or 4.0/(40) depending on the setting device. Lower setting limit, MPa/(bar)-0.15/(1.5) or 1.2/(12) depending on the setting device. More information on our website.

Request for a quote

EKINEX

Italy

The Ekinex® products for temperature control are grouped in fancoil, electrothermal actuator and mixing group controllers. Fancoil controllers are KNX devices that operate as actuators or both actuators and room temperature controllers for air terminals such as fans, convectors and fancoils. The Ekinex® S-mode KNX devices for electrothermal actuator and/or servomotor control for zone valves are installed on the supply manifolds of the radiant plants or radiators. The mixing group controller regulates the supply temperature of the heating fluid using a selectable regulation mode, separately for heating and cooling.

Request for a quoteResults for

Zone valves - Import exportNumber of results

9 ProductsCompany type