- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding electrodes

Results for

Welding electrodes - Import export

PEMAT S.C.

Poland

ESAB OK GoldRox 1kg 2.5mm 6013 RUTILE ELECTRODES IGNITE THE GOLDEN ARC OK GOLDROX ELECTRODE BY ESAB - A HIGH-QUALITY COATED ELECTRODE FOR ALL POSITIONS. The 6013 OK GoldRox rutile electrodes offer excellent performance in everyday manual welding tasks, enabling welders of all skill levels to perform them successfully. EASY ARC IGNITION. With OK GoldRox electrodes, ignition and re-ignition are no problem, even when using welding power sources with low idle voltage. EASY SLAG REMOVAL. Using OK GoldRox electrodes allows easy removal of slag, saving time and money in the post-weld cleaning phase. MINIMUM SPRAY. Thanks to the excellent arc stability, OK GoldRox electrodes leave less spatter than standard 6013 electrodes.

Request for a quote

PEMAT S.C.

Poland

The ESAB Handy 200 A electrode welding torch is intended for welding with MMA coated electrodes. It is equipped with a revolving handle with two holes for electrodes. The holes are set at 45 and 90 degrees. After inserting the electrode into the selected hole, clamp the electrode by turning the handle. In this way we ensure comfortable, strong and secure electrode mounting. ADVANTAGES OF THE HANDLE: recommended maximum welding current in a 35% cycle: 200A Diameter of the clamped electrode: 1.6-5 mm Combined welding wire: 16 - 50 mm2 completely isolated handy, allows welding in all positions high quality ensures comfortable, strong and secure electrode mounting the ability to set the electrode at 45 and 90 degrees allows welding in various positions

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

The Invertec® 165S and SX welders offer much more than you would expect from a welder of this size. They have all the power of a heavy-duty professional welder that you can take to the most demanding job sites. Low energy consumption and high duty cycle: they are ideal for maintenance and for all professional, industrial or construction site applications. Exceptional performance: high duty cycle at 40°C. Easy to use: Hot Start function to improve arc strike and Arc Force function to prevent electrode sticking. Versatile: welding with any coated electrode (except cellulosic) Compatible with motor-generator. Light: less than 9 kg Practical: thanks to the practical carrying strap.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

COMPANY TOR

Russia

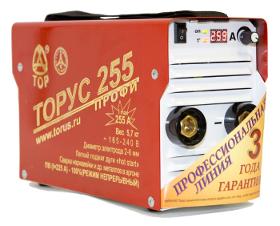

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quote

COMPANY TOR

Russia

Operating from a single-phase 220 V network, the industrial welding inverter ТОРУС-250 Extra has an increased arc welding current up to 250 Amperes and, therefore, an increased percentage of operating time (TP). This allows performing continuous welding works: the device provides TP = 100% at an arc welding current of up to 225 Amperes (electrodes with a diameter of 5 – 6 mm). The power consumption when welding with “household” electrodes with a diameter of 3 mm is such that the device can be connected to a regular household outlet. Thus, the ТОРУС-250 Extra device is universal for industrial facilities and for cottage areas.

Request for a quote

COMPANY TOR

Russia

The VIKING TIG 315 AC / DC PRO argon-arc welding machine is a one-piece structure, designed for power supply from a three-phase 380 V network and produces 315 A at a load of 60%. Special software functions significantly increase the performance factor of the device: HOT-START, ARC-FORCE, ANTI-STICK functions. Specifications: Voltage: V380 Max power: kW5.5 Max current: A315 Operating mode: DC/AC Product class: Professional Burner operating mode: 2-stroke / 4-stroke Pulse mode: yes Availability of the button for saving the selected parameters “MEMORY”, allows you to program 10 parameters for each welding mode (AC/DC). PULSE welding mode is a pulsed consumable-electrode welding (Possibility to use both direct current (DC) and alternative (AC). Waveform selection function (available in AC mode). Dot welding mode 2T and 4T. Adjusting of smooth drop of the terminating current. Adjustable inductance.

Request for a quote

COMPANY TOR

Russia

The inverter machine VIKING 500A PRO is used for manual arc welding of metal blanks. The inverter has a functional control panel with a digital display that displays the main operating parameters. The device is equipped with overload protection and voltage surge protection. The technologies applied during the manufacture of VIKING 500A PRO devices allow performing any tasks in welding, surfacing and cutting metal structures for performing work with any kind of electrodes with a diameter of up to 6 mm and a maximum arc welding current of up to 500А (100% at 420 A). The welding inverter machine can be used at low temperatures and reduced supply voltage. Adjustable functions of hot start and arc reheat imply the ability to adjust the operation of the device with minimal spattering and allow you to perform work in any spatial position of the electrode and welded surfaces.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Wire rod is an excellent consumable for the production and manufacture of knitting, spring, welding wire; electrodes for electric arc welding; hardware products; masonry and other mesh; ropes (cable) ; formwork manufacturing; concrete structures; metal structures . Wire rod can be either hot or cold rolled carbon steel. It is drawn on special drawing machines by drawing to a thickness of 5 to 15 mm onto special winding spools. The weight of one coil of wire rod is on average from 160 kg, depending on the initial diameter, order or consignment of goods. A circle of small diameters is made from rolled hot rolled wire by cutting; the product can also be supplied in bars. Quality The quality of the wire rod corresponds to GOST 30136 and is confirmed by certificates. Steel grade 3PS, 1PS, 2PS, 1KP, 2KP, 3KP, 1SP, 2SP, 3SP. Rolled wire is produced with the following strength classes B standard; B increased. You can contact us by mail - marketing@stalevar.

Request for a quoteResults for

Welding electrodes - Import exportNumber of results

11 ProductsCompany type