- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting process

Results for

Cutting process - Import export

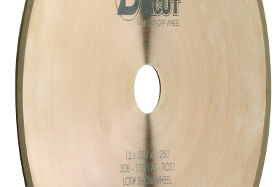

WMC SINTERSTAR AG

Switzerland

Diacut cutting discs in diamond and CBN are characterised by a high cutting ability and efficiency in the cutting process.

Request for a quote

RONIX GMBH

Germany

Ronix RH-3510 & RH-3511 Granite Cutting Discs are manufactured by cold press production process with fully automated machines. These wheels are produces in a way to ensure faster cuts and longer lifetime of the cutting disc itself. To provide the users with a great granite and marble cutting experience, the highest quality materials are used in the production of these Ronix cutting discs. The unique formulation of materials in the diamond tips of these discs, minimizes friction between the workpiece and the blade which results in a faster and cooler cut. Since granite is a highly durable and resistant material, the process of cutting it causes a lot of friction. This is why many people prefer to add water and other liquids to the cutting process to cool down the disc in order to protect it. For this reason, we at Ronix manufacture our granite and marble cutting discs so be suitable for both wet and dry cutting to suit a wide range of consumers’ needs.

Request for a quote

FUSED MACHINERY

Belgium

Mild Steel 20mm/ stainless steel 15mm/Aluminium 12mm High quality cut edges throughout machining process High performances CO2 cutting optics Machine is in good condition and can be inspected under power Availability: 01/2023 More information and video on request

Request for a quote

SHAPEYOURGLASS

Belgium

Glass cutting is a complex process requiring innovative technologies. Our lasercut technique allows many possibilities in terms of shape whether straight or rounded. Moreover, this step does not alter the resistance of the glass and provides highquality straight edges finish.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METALLSTANDART LTD

Russia

High-speed tool steel Application: All types of cutting tools used to process carbon alloy structural steels, mainly threading tools and tools operating with impact loads.

Request for a quote

METALLSTANDART LTD

Russia

High-speed tool steel. Application: All types of cutting tools used to process carbon alloy structural steels.

Request for a quote

METALLSTANDART LTD

Russia

High-speed tool steel. Application: All types of cutting tools used to process carbon alloy structural steels.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 063 Cutting, stamping and bending device for radial components Description The device processes power transistors and diodes to the types of housing TO 92, TO 18, TO 126, TO 127 and TO 220 with a maximum of three radially running connections. However, other components can be processed (for example, LED). The cutting and bending of the connecting wires is carried out in one step and of course including cable strain relief in order to avoid axial forces on the component housing. When a component which is to be bent, embossed and cut, two processing stations are necessary. Components

Request for a quote

PROTEC TRADING GMBH

Austria

English | Deutsch | Español | Português | Français | Italiano | Русский Visit our website for information in your language. Laser-Lotion PROTEC LC20A Anti-spatter agent PROTEC LC20A is optimised to protect sheet metal panels, pipes, profiles and equipment (supports). Protects any type of metal surface from spatter (steel, stainless steel, aluminium, etc.) No silicone, non-flammable and biodegradable. Laser-Lotion PROTEC LC20A ensures increased quality by preventing spatter, providing dry and clean metal surfaces, no reworking required, as well as higher productivity of the laser system as the beam moves more easily following penetration. Another customer benefits are reduction of cleaning efforts and longer lifetime for the grating (support bars) of the flatbed laser system. • No residue and a particularly low level of emissions • Process safety, also during follow-up processes (vibratory finishing, welding, etc.) • Suitable for all conventional coating

Request for a quoteResults for

Cutting process - Import exportNumber of results

11 ProductsCompany type