- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vices jaw

Results for

Vices jaw - Import export

NORELEM FRANCE

France

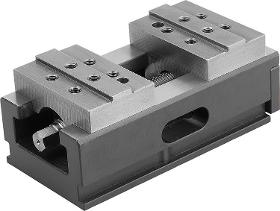

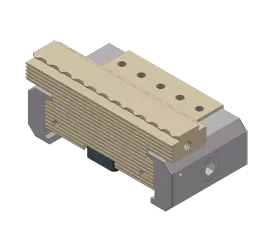

Body and jaw holder hardened and ground. Note for ordering: Supplied with hexagon crank handle. Order jaw plates separately. Note: Mechanically operated centric vice. Suitable for automation: prepared with gripper slot for handling systems. Flexible mounting: suitable for zero-point systems, mounting on machine tables or on custom systems via a baseplate. Centring precision: +/- 0.02 mm. The use of a torque wrench is recommended to achieve a controlled clamping force. Features: Clamping slide and spindle nut in one piece Slots and fastening threads for mounting attachment jaws Reversible jaws (accessories) with lateral thread for workpiece stop enables a wider clamping range Good swarf and coolant removal

Request for a quote

NORELEM FRANCE

France

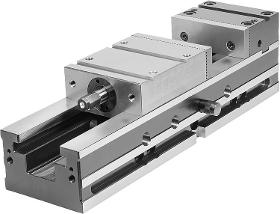

NC vices can be used for a wide range of clamping tasks: Repeat accuracy ≤0.01 mm Fixed jaw locked in all directions (X,Y,Z) Vertical use directly on the machine table Wide clamping range by using attachment step jaws Can be laid on the side, with fastening holes for slot spacing of 63 mm and 100 mm Quick pre-adjustment of the clamping range using locking pins Basic equipment includes two reversible screw-on jaws and one crank handle

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

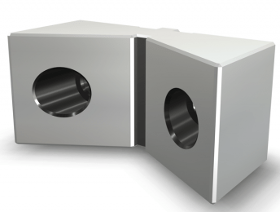

Easy machining of round workpieces High precision and high clamping force Wide range of accessories for flexibility Maximise your machining envelope Fixed v-jaws for the SVF range of flexible vices. There are bolt-on hard v-jaws to fit all types of fixed jaw in the SVF range including wedge type and non-wedge type. These v-jaws have a centre key for accurate positioning.

Request for a quote

NORELEM FRANCE

France

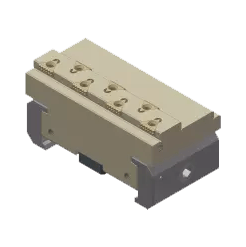

The 5-axis vice features excellent stability and flexibility, and is extremely easy to use. The 5-axis vice can be used as a positive-down force vice or normal vice. When the positive down force function is used, the workpiece can be held with a repeat accuracy of ±0.01 mm. A workpiece clamping height of 180 mm enables easy access during machining. The clamping width is preset using the crank handle, cutting down on setup times. Additionally, the closed geometries and the resistance to dirt that they provide keep maintenance and repair times to a minimum.

Request for a quote

PROSAW LIMITED

United Kingdom

Heavy Duty Automatic Bandsaw for solid bar, bundles & general sawing with the following features: Vice feed automatic with encoder for precision length set Twin hydraulic vices clamp both sides of material Simple input of component length and number of pieces via touch screen Steplessly variable blade speed 17 ~ 67m/mm Hydraulic blade tension control for optimum blade life. Variable downfeed control. The touch sensitive control screen provides easy selection of precise bar length requirement for a precise cut off length. The auto head-elevation reduces index cycling time significantly. The Blade speed is set and adjusted by acting on the touch sensitive control screen. There are quick-adjusting carbide saw-band guides, there is an idle wheel motion protector, a hydraulic band tension control, a quick-action HYDRAULIC twin-vice (split vice) 3-jaw clamping, a unique two-way vice jaw and an automatic chip conveyor.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Conventional and CNC-controlled milling machines – for efficient precision machining -Horizontal installation – great variability and flexibility Product features : -Excellent ease of operation guarantees optimal handling in every situation -Fast adjustment for clamping range preselection -The clamping force is generated and preset via the hydraulic pressure of a hydraulic unit -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped -Coarse adjustment is performed by turning the spindle. The residual stroke of up to 4.5 mm is performed via a hydraulic unit with spring reset by means of a single-acting cylinder

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench Integrated scrapers ensure functional reliability and minimise cleaning Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

HF HAYTEK PLASTIC AND PLASTIC MACHINERY CO.

Turkey

Planetary saws, equipped with disk and milling cutter for cut and chamfering of PVC pipes (rigid and foam) or other plastic materials; Swift replacement of tools, even with pipe in movement; Pipe blocking vices or iris mechanism jaw system. Suction device with double filter and sound-proofing; Automatic synchronisation with extrusion speed.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick Change Mechanism Hardened for Longevity Clamping Surface is Grooved to Avoid Marking Component Custom Sizes Available For clamping workpieces that must not be damaged. The clamping surface is grooved and not ribbed. This results in reducing the potential for marking components. The stepped jaw is hardened approx. 0.2 mm deep. The accuracy of the surface with respect to the serration is +/- 0.02 mm. For greater accuracy, the jaws must be ground in tension on the vice.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick Change Mechanism Hardened for Longevity Gripping Serration is 3mm deep to Reduce Waste Material Requires Low Clamping for during Machining, Reducing Deformation Gripper jaws can reduce the risk of the part being torn out under high machining forces. The penetrating tips produce a very high holding force even at low clamping force.

Request for a quoteResults for

Vices jaw - Import exportNumber of results

12 ProductsCountries

Company type