- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precise

Results for

Precise - Import export

VALDAMARK LIMITED

United Kingdom

The Hawo® HD 650 D/DE/DC EcoPak® is a top-tier medical continuous sealing machine designed for precision and efficiency in sterilisation packaging. This robust, versatile tool is essential for healthcare facilities, medical device manufacturers, and industries demanding secure, sterile packaging.Key features include continuous sealing for uninterrupted operation, adjustable temperature and speed for material adaptability, and dual/triple sealing options for enhanced protection. Its integrated cutting mechanism, compact design, and user-friendly interface streamline workflow. Built to meet stringent medical standards, the machine offers reliable performance, easy maintenance, and wide packaging compatibility.Energy-efficient EcoPak® models reduce costs without compromising power.Ideal for sterilising instruments, packaging pharmaceuticals, implantables, single-use items, and consumables, the HD 650 D/DE/DC EcoPak® safeguards product integrity and patient safety.

Request for a quote

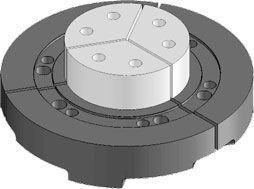

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Universal quick change system for any chuck Repeatability < 0.001" TIR Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems DESCRIPTION When it comes to turning/holding smaller diameter parts Abbott’s precision master plate and segment system is an ideal choice for high changeover and short running jobs. Due to the system’s high repeatability, it is an excellent alternative to more expensive quick change chucks. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is bored and bushed to accommodate Abbott’s standard, off-the-shelf pinned segments. Plates are available in 8, 10 and 12 inch diameters and can be mounted on 4-12 inch diameter chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments

Request for a quote

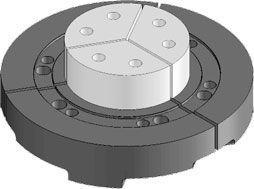

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Universal quick change system for any chuck Repeatability < 0.001" TIR Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems DESCRIPTION When it comes to turning/holding smaller diameter parts Abbott’s precision master plate and segment system is an ideal choice for high changeover and short running jobs. Due to the system’s high repeatability, it is an excellent alternative to more expensive quick change chucks. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is bored and bushed to accommodate Abbott’s standard, off-the-shelf pinned segments. Plates are available in 8, 10 and 12 inch diameters and can be mounted on 4-12 inch diameter chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Precise - Import exportNumber of results

3 ProductsCountries

Company type