- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cylinder design

Results for

Cylinder design - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compact and lightweight Built in check valve and pressure relief valve Built in sensor switches Optional through coolant or air Closed centre cylinder with compact design and built in Rotary Joint for through air or coolant capacity. Features include built-in check and pressure relief valve along with stroke sensor switches as well as rotary joint.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compact short body design Increased max operating speed Increased pull force gives larger chuck range Kitagawa hydrualic cylinders are made with high grade alloy steel. The SS series cylinders are compact design to fit on size critical machines while giving a larger pull force to allow for operation of a wide range of chucks. The cylinder can be bought as a single unit or to suit a required machine under request.

Request for a quote

BUDENBERG GAUGE CO LTD

United Kingdom

The BGP base can be used with any BGP series piston, allowing testing from 15 mbar to 120 bar. The base requires a supply of gas slightly above test pressure, and has precision inlet / outlet valves and a screwpress to enable easy regulation and adjustment of pressure. The BGP1 has a 1/2in2 high chrome steel piston/cylinder unit. The design has been proven over many years to provide excellent sensitivity and stability. Low start pressure is achieved through use of a hollow piston and aluminium head. NOTE: Model BGP1 can be used on vacuum with a model 24 adaptor. All certificates issued for Budenberg Dead-weight Testers are fully traceable to national standards via equipment with UKAS calibration certificates.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

From the sticky tar sands of Uzbekistan and the frozen windswept wastelands of Ural to arid, sun -leached Texas and the sizzling hot deserts of Saudi Arabia; from the warmth of the Caspian sea to the cold salt spray of the ocean, Gidrolast hydraulic cylinders are the actuators of choice in the gruelling oil field industry, both onshore and offshore. Oil rigs are located in some of the most demanding locations in the world. Blowing sand, sticky tar, extremes of hot and cold temperatures, corrosive elements and heavy-duty use. The cylinders used are often large-bore and long-stroke. Downtime is measured in millions of dollars. In addition to all that, the equipment is often located in remote areas far from civilization. Rugged, reliable cylinders are a must. Gidrolast designs and builds heavy-duty hydraulic cylinders, both rod style and telescopic, to withstand the tough conditions and demanding requirements of the petroleum industry.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

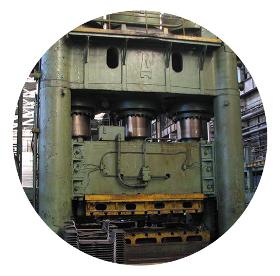

Metallurgical equipment all endure heavy-duty service under very demanding environmental conditions. Equipment is subjected to moisture, dirt, saw dust, wood chips, sap and tar and slamming loads. The hydraulic cylinders used on that equipment must meet these challenges day after day. Gidrolast has over 15 decades of experience building hydraulic cylinders for this tough industry. In fact, you could say we cut our teeth in the forestry industry. For our customers, that experience is invaluable. Gidrolast designs cylinders that are able to endure the difficult conditions that metallurgical machinery encounters on a daily basis.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GIDROLAST CO., LTD

United Kingdom

Gidrolast knows heavy trucks. We cut our teeth building hydraulic cylinders for heavy trucks all the way back in 1993. Hydraulic cylinders on trucks are subjected to all forms of contamination that would destroy a poorly designed cylinder. Dirt, grit, rain, salt, tar, chemicals, solvents and cleaning agents all combine to attack the cylinder and its seals. Despite all this, the cylinders are still expected to perform. Cylinder failure means downtime, employee overtime, loss of vehicle availability, less productivity and reduced profit. Gidrolast cylinders are built tough to meet these conditions. They can be found mounted on garbage trucks, dump trucks, belly dumpers, semi end dumpers, boom trucks, knuckle boom loaders, road pavers, concrete mixers, concrete pumps, mobile cranes, tilt beds and tow trucks. Applications include dump cylinders, aerial boom cylinders, compaction cylinders, outrigger cylinders, tilt cylinders, swing cylinders, plough lift cylinders, and more.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast got its start in building rugged hydraulic cylinders for use on heavy trucks in the waste management industry way back in 1994. That means we know first-hand what is required to build cylinders that will tough it out in this industry. So whether the cylinder is operating the gate on a garbage truck or the grapple in a scrap metal yard, the compactor on a scrap baler or lifting the blade of a bulldozer in a land fill site, Gidrolast cylinders are built to last. Both OEMs and end users around the world appreciate the rugged reliability built into each of our cylinders. Careful, experienced design is combined with high-quality manufacturing to make our Gidrolast hydraulic cylinders the cylinders of choice in waste management and recycling equipment. It’s not hard to see why tough, reliable cylinders are required in the waste management and recycling industry, as these pictures clearly testify. Hydraulic cylinders are shown in action in a scrap metal yard above.

Request for a quoteResults for

Cylinder design - Import exportNumber of results

8 ProductsCompany type