- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- watchmaker's machinery and equipment

Results for

Watchmaker's machinery and equipment - Import export

BALKAN MOTOR SANAYI VE TICARET A.S.

Turkey

The newest touch-screen product Smart Polishing Bench. While designing this product, we have keep in mind our customers who prefer the entire convenience of a polishig bench and maximise their satisfaction. This Exceptional Polishing Bench which is equipped with the highest quality materials and the latest technology, gives you the flexibility to work at any speed between 300 and 3000 rpm. Exceptional touch screen. There are no any switches. Exceptionally easy operation, precise speed adjustment and display. All settings will be made via high-tech touch screen. Maintenance-free, quiet and high-performance powerful motor. Water resistant 304 quality stainless steel body. 750 m3 Vacuum with superior suction power. 3 filtration System which has fine dust separation and easy to clean. 4X9 1600 lm Daylight Led Lighting. Movable transparent plexiglass protector.

Request for a quote

BALKAN MOTOR SANAYI VE TICARET A.S.

Turkey

The Superior Technopolish Polishing Machine which is quipped with the highest quality materials and the latest technology, runnings at two speeds as 1500 and 3000. Thanks to its ergonomic design, it is compatible with all kinds of working conditions. It has an arm support that provided to you work tirelessly. Thanks to the buttons it is easy to use and trouble-free. Ergonomic design. Maintenance-free, quiet and high-performance powerful motor. Water resistant 304 quality stainless steel body. 750 m3 Vacuum with superior suction power. 3 filtration System which has fine dust separation and easy to clean. 4X9 1600 lm Daylight Led Lighting. Movable transparent plexiglass protector.

Request for a quote

ROBINSON CO.

Turkey

The Air Channel is used for cleaning wheat, barley, legumes and soybeans. The machine removes all kinds of light materials different from cereal grains in terms of aerodynamic properties: garbage, straw and spike fractures, various seeds, peeled shell and dust from the product by means of air flow. While the grain products are distributed homogeneously in the width of the Air Channel with the feeding table of the machine or a vibrating feeder, the light particles in it are conveyed to the upper outlet channel with the air flow coming from the bottom, and the cleaned product falls down and transferred into the system. ◾ The lighting created by the window enables the separation to be seen clearly and thus all kinds of air adjustments can be made. ◾ Manufactured in two types, this machine with vibro motor is usually used with a Peeler machine, the non-motorized one is used with a Garbage Purifier machine.

Request for a quote

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants.

Request for a quote

ROBINSON CO.

Turkey

It is utilized as a part of the flour plants to isolate any outside material that might be blended into conclusive item amid processing procedure or capacity. The remote materials isolated from item before pressing, item stockpiling or mass stacking storehouse. FEATURES - MFDJ It is utilized as a part of the flour plants to isolate any outside material that might be blended into conclusive item amid processing procedure or capacity. The remote materials isolated from item before pressing, item stockpiling or mass stacking storehouse. - MFNM - Best machine in practice. - Most economic spare parts. - Long life. - Seperation of fat with intensive operation. - Nindamac helps to achive high aqualit diffrent granulation of finished product with low fat content. For high technology degermination done by Nindamac by the

Request for a quote

ROBINSON CO.

Turkey

While the grain is carried upwards with the anchors made of hard material resistant to abrasion formed in appropriate dimensions on the rotor in an angled semi-cylindrical body made of stainless steel, the water is absorbed by the grain by subjecting it to intensive mixing at a measured speed. It is used in grain processing plants to ensure that the desired moisture content of the grains penetrate and feed the grain sufficiently. It brings the grain to be annealed with water and provides a homogeneous mixture. At the same time, a significant amount of peeling is ensured in the grain shell as a result of friction caused by the rotor rotating at high speed. Application Fields ◾ At food industry ◾ At the dry cleaning units of the flour and semolina mills ◾ At the grain processing plants where moistening process is required

Request for a quote

ROBINSON CO.

Turkey

Thanks to the belt-pulley mechanism driven by an electric motor, the rotational motion is transferred to the sieve shaft. The sieve weights, which are placed unbalanced, connected to the sieve shaft, make the sieve vibrate. The position of the screen weights can be adjusted around the screen shaft in order to change the vibration amplitude of the screen. The screen is hung on the ceiling of the place where it is located by means of composite rods in order to create the vibration comfortably. Thanks to this vibration movement, in specially designed sieve boxes, the incoming product is classified and sifted according to its grain size. The product to be screened is sent to the screening area through one or more inlet pipes. Various types of silk-covered cases allow separation in seven channels. This part is directed to the outlet by the channel. After the product is sifted, it is sent to the outlet pipe on the bottom plate. It also has sight pipes for product control and monitoring.

Request for a quote

ROBINSON CO.

Turkey

It is used for breaking and crushing wheat in flour factories. The most important machine of the flour mill, the roller mill consists of two pairs of roller balls operating in parallel. Unlike the pneumatic roller, the incoming product amount is measured with the help of a sensor or load cell. Feeding rollers change speed according to the incoming product amount and provide homogeneous flow. At the same time, the gap between the rolls is closed by pneumatic pistons and allows the product to be grinded by passing through the rolls. The bearings of the rolls are ductile iron and the arms of the rolls are conical. It is produced with gear drive and belt drive. It can also be produced with an optional touch control screen. Especially thanks to the side covers that can be opened one by one based on the opening system, it provides fast and easy access and the possibility of rapid ball removal with the cover opened on the ball.

Request for a quote

ROBINSON CO.

Turkey

By separating the flour particles adhered to and remaining in the bran, it both prevents the loss of flour and increases the efficiency. Thanks to the special pallets on the rotor that rotates horizontally, the flour is separated from the bran while being thrown towards the screen. The centrifugal directed product strikes the pore size preselected screen. Thus, it is ensured that the flour particles are directed to the outside of the sieve and the bran to the outlet channel from the inside. Applications Fields ◾ Flour Mills ◾ Semolina Mills

Request for a quote

ROBINSON CO.

Turkey

Bucket elevators are used to transport granular or powdered products with buckets attached to their belts from the bottom up. They are manufactured in various sizes and capacities according to the needs. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

This machine is utilised for blending of various sort of grain as asked for rates and conformity of limit before processing area or treating segment. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

Moving through the centre, the product is transported to a horizontally positioned blade rotor. During rotation, the product is pushed against the wall of the machine and the eggs, if any, are destroyed inside the machine.

Request for a quote

ROBINSON CO.

Turkey

Instantly measure and display of humidity and hectoliter of wheat Calculation of water flows according to the required humidity. Automatic water dosage according to the calculated water flow value Automatic water dosage according to the wheat flow variation by the connection of wheat flow control or measure unit Alarms of failure More than one humidity – hectoliter measuring unit and water the dosage unit can be controlled by the PLC control unit.

Request for a quote

ROBINSON CO.

Turkey

Flowing the dry cleaning of wheat, it is used for the humidity of wheat with a little consumption of water and time. At the same time, the wheat is unshelled also because of the two rotor, which turns with high speed.It can add up to 7% of water in a single flow-through.

Request for a quote

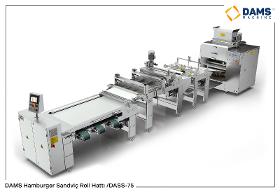

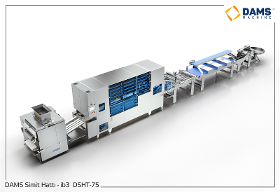

DAMS MACHINE

Turkey

Roll Bread Packaging is done one by one. Thanks to the touch screen and PLC, there is easy access and intervention to the package size of the product, intelligent eye photocell adjustment and machine speed. Our Machine has intelligent motor system servo motor automation. There is a product control sensor that prevents the Roll Blower or other products from being jammed during packaging. During packing, the packaging does not crush the bread. If the location of the plant is not suitable, the intelligent eye sensor stops the machine. The machine is also made of 304 quality stainless chrome-nickel metal suitable for all surfaces that contact with the product and environmental protection covers. Our machine has been produced on the product in accordance with the operation of the device which outputs information such as date of production-serial number expiration date. This machine is optional. Emergency Stop has been put in place to provide user and machine security.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

PRODUCT SPECIFICATIONS It has an air blowing system. It has a flouring system. It works silently and has a long life. It is made of 304 quality stainless steel.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMS MACHINE

Turkey

DSPM series are standard mixers. It has a double-speed motor and belt-pulley equipment. The dough mixing process is completed in 18 minutes. It can be used in making dough, meatballs, butter, minced meat, cream, tobacco, cookies and similar products. PRODUCT SPECIFICATIONS Time setting Reinforced body Double-speed motor Parts in contact with food are made of 304 quality stainless steel. Electrostatic oven painted surface

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use. Optionally, it is produced so that a coding device can be mounted on the machine. Cellophane bobbin is easy to disassemble and install, the place where it is mounted is an air system and PLC controlled shaft.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

DMOM series are new generation mobile bowl mixers. It has a fast and practical system that allows kneading without losing time thanks to the spare mobile bowl.It has a double-speed motor and belt pulley equipment. The anchor lifting and bowl locking systems are hydraulic. Slow and fast cycle times can be determined by setting the time with the automatic operation mode.It has a faster kneading feature than standard dough kneading machines and the dough kneading process is completed in 15 minutes.It is aimed at meeting fast mass production needs. It can be used in the production of dough, raw meatballs, butter, minced meat, cream, tobacco, snacks and similar products. PRODUCT SPECIFICATIONS Touch Screen PLC Control Panel Hydraulic bowl locking and anchor lifting Differential-free system Water dosing Time setting Double-speed and powerful motor All surfaces in contact with food are made of 304 quality stainless steel

Request for a quote

DAMS MACHINE

Turkey

DKDM series is designed to save time, energy and especially to make hygienic production by transferring the dough in the GKHYM series mobile bowl to the desired environment in a practical way. PRODUCT SPECIFICATIONS Hydraulic lifting system Reinforced body Parts in contact with food are made of 304 quality stainless steel Quiet operation Emergency stop button Lifting and lowering function with a single press Electrostatic oven painted surface "DKDM -700 It is prepared with special dimensions upon order."

Request for a quote

DAMS MACHINE

Turkey

DYMK series are spare mobile bowls suitable for DMOM series. It provides the opportunity to work non-stop with the spare bowls

Request for a quote

OKSUZOGULLARI HORECA VE EV GERECLERI A.S

Turkey

Made of 304 chrome 18/10 stainless steel. Its body and strainer are stainless steel. It provides long-term deterioration of tea flavor. Provides suitable use for mass consumption. It is hygienic and long-lasting. It is economical with its automatic heat control system. Water heating system has been specially designed. Provides tea brew and hot water that does not stale throughout the day. It is equipped with a rust-free shock tube resistance that boils water. Provides ergonomic use with special model taps.

Request for a quoteResults for

Watchmaker's machinery and equipment - Import exportNumber of results

83 ProductsCountries

Company type

Category

- Bakery - machinery and equipment (24)

- Bakery and confectionery industry - machinery and equipment (19)

- Milking - machinery and equipment (18)

- Axles, vehicle (18)

- Bakery - machinery and equipment (17)

- Flour milling - machinery and equipment (16)

- Pastry-making - machinery and equipment (15)

- Textile dyeing (9)

- Textile dyeing - machinery and equipment (9)

- Food industry - machinery and equipment (2)

- Bottling and filling - machinery and equipment (2)

- Dairies - machinery and equipment (2)

- Jeweller's, watchmaker's, gold- and silversmith's machinery and equipment (2)

- Butchery - machinery and equipment (2)

- Jeweller's machinery and equipment (2)

- Jewellery (2)

- Mining and quarrying - machinery and equipment (1)

- Packing and packaging - machinery and equipment (1)

- Beverage industry - machinery and equipment (1)

- Brick-making - machinery and equipment (1)