- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wet processing

Results for

Wet processing - Import export

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Wet processing-washing is, in most cases, cleaning and separation of materials by use of water and mechanical forces. It is often followed by the removal of such impurities from raw materials as ores, minerals, sand, and gravels. The process commences by the introduction of the said raw materials in a wash plant and thorough soak with plenty of water. This initial saturation softens and loosens the unwanted materials, making them easier to separate from the valuable base material. Inside the wash plant, zones of high pressure and the whirling impact of paddles and jets alternately whip and beat the mixture, scouring away dirt, clays, silt, and all other contaminants. The continuous movement of water helps to further dislodge these impurities, allowing for a more thorough cleaning.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The water treatment plant for a recycling plant is a facility that is specifically designed to treat the wastewater from the recycling operations of most industrial sectors. The function of water treatment facilities is to ensure that, upon discharge, the water from a recycling plant meets the required regulatory and environmental standards before being either released into the environment or reused back into the facility. The treatment process typically includes physical, chemical, and biological modes of treatment for the scavenging of pollutants, contaminants, and suspended solids from a wastewater stream. Applying processes such as filtration, sedimentation, disinfection, and biological treatment, water treatment plants for the recycling plant ensure that high-quality and environmentally safe treated water for discharge or reutilization, with the overarching goal of promoting sustainable water management practices.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

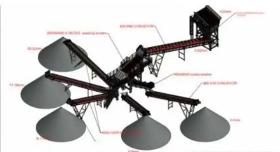

A Sand and Rubble Recycling Plant is a plant that processes and reuses demolished concrete, bricks, asphalt, and other such wastes to produce recycled products like aggregates and sand for use in construction projects. These plants used to recycle materials carry application in cities for the collection of wastes, sorting, breaking, screening, washing, and grading to get a product that may have the value for the customers. The reason may be that the aggregates produced in the plants can be used in construction by substitution for aggregates, which will lead to reduced demand for new aggregate resources and less waste landfill. As well, the recycled sand derived from the rubble may be used for applications such as construction, landscaping, and road works, providing a cleaner alternative yet ensuring the sustainability of the construction industry. Recycling plants for sand and rubble have advanced machinery and equipment that work productively to process and recycle waste materials.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Filter press systems are equipment used in separating solids from liquids in various industrial processes. The system includes a series of filter plates arranged in a stack within a filter press unit. The plates are normally covered with filter cloth or filter medium that will allow the liquid component to pass through while holding back solid particles. During the process of filtration, a slurry or suspension is typically pumped into a filter press, where pressure is applied that squeezes the liquid component through the filter media, leaving solid particles trapped within the filter cakes. Afterwards, these cake solids are discharged from the filter plates, and the clarified liquid is discharged at the end of a filtration process to have efficient separation and dewatering of the solids from the liquid phase. Filter Press Systems find their application in a wide array of industries, such as chemical processing, wastewater treatment

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Compact Sand Washing Plants are small, specifically designed plants developed for the effective cleaning and separation of sand particles in industrial applications. Most of the plants consist of a combination of equipment, including a sand washer, dewatering screen, hydrocyclones, and fine material washers, all integrated into one compact and mobile unit. Compact Sand Washing Plants are mainly designed to remove impurities, silt, and contaminants from sand to leave the final product clean, well-graded, and fit for use in construction, concrete production, and other industrial procedures. These plants integrate several washing and screening mechanisms in an integrated compact design, ensuring high effectiveness in washing and dewatering sand while guaranteeing better output quality at space and operationally lower footprints.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Deep Cone Thickener Tank is a plant process equipment used in separating and concentrating solid-liquid mixtures in mineral processing plants, wastewater treatment facilities, and other industrial processes. This tank features a cone-shaped bottom that allows efficient sedimentation and thickening of fine particles and slurry. During entry of the mixed slurry into the tank, the solids settle to the bottom due to gravity and form a dense cake; the clarified liquid overflows from the top. The deep cone design of the tank provides an increased settlement area and steep slope angle, facilitating the separation and thus assuring maximum concentration of solids in the underflow. The Deep Cone Thickener Tanks find wide application in processes where thickening, dewatering, or separation of solid-liquid is required with high efficiency in attaining the desired levels of concentration and clarity of liquids.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Fine material washers, otherwise known as spiral classificators or screw washers, are typically utilized in the aggregate and mining industries to clean fine materials such as sand, gravel, or even crushed stone. This machine contains a rotating screw shaft enclosed in a trough that conveys a water/material mixture. While the materials are being moved along the screw shaft, the agitating and rotating action of the screw enables the washing and separation of the finer particles from the coarser ones. Water is introduced at the same time into the system to aid washing for the removal of impurities, then leaving fine, drier materials that are ready for further processing or stockpiling. Fine material washers are used to process fine materials into high-quality and pure materials that can be applied in construction and in the production of concrete, among other uses.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

he coarse material washer is designed for mining, aggregate processing, and construction industries to clean and wash large and coarse materials. This washer is designed to handle larger size materials like gravels, stones, or oversized particles that may contain clay, dirt, or other impurities. It generally consists of a trough or tank into which material/water mixtures are fed, with paddles or blades agitating and scrubbing the coarse materials during transport through the machine. Coarse material washers scrub larger particles clean by dislodging unwanted contaminants; the materials are washed properly so that they can be further processed or used for various applications. In operation, the coarse material washer receives oversized materials that are to be cleaned, and paddles or agitators inside create a scrubbing action that will effectively clean and wash large particles. Water mixes with these materials to aid the washing process in removing dirt, clay

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The log washer is a unique, heavy machinery equipment used in mining, aggregate processing, and mineral processing to clean and scrub ores, rocks, and minerals. This machine comprises an enormous shaft shaped like a log with paddles or blades which turn and shake the material in a container that can be filled with water or washing solution. The log washer paddles turn to generate a scrubbing action, thus driving their fruit, while lubricating forces remove the contaminants in the form of clay, silt, and other impurities. Supported by an aggressive action, the log washer acts to break down and remove unwanted materials while delivering a cleaner and more refined product. These particular applications have proven to work quite well with log washers, taking into consideration material preparation for further processing or to meet required quality specifications that call for thorough cleaning and scrubbing.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The bucket washer/dewaterer is specialized machinery used in agriculture, food processing, and recycling industries for cleaning and separating materials. It features a rotating drum or a series of buckets that dips in the water, agitating the materials to free them from dirt and debris, and lifts them out of the water for dewatering. These effectively wash the materials, dewater them for further processing or packaging. Bucket washers/dewaterers have gained prominence in the production of fruits, vegetables, nuts, and any other small, solid products that require washing effectively and drying prior to processing or resale to the consumer. A classificator, otherwise known as a classifier, is a mechanical device sorting or classifying materials into size, shape, or density categories. Generally, a classificator includes a screening surface with holes or slots of different sizes through which materials are passed.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A dewatering screen is an apparatus primarily used in mining, aggregate processing, and recycling industries for ridding water from sand, gravel, and other solid materials. This becomes necessary in removing water from a substance to reduce the moisture content so that it can be handled and transported with ease, processed further, or even possibly stored. It operates on high-frequency vibrations, which drive out the water from the screens, leaving the solid material at the surface of the screens. The material is conveyed along the vibrating screen deck and the expelled water separates away, leaving a drier, more manageable product in its wake. The ability of dewatering screens to perform moisture control is essential for the effectiveness of many industrial processes. Preparing sand for the production of concrete, or ore for further processing after mining, will require guaranteed moisture content of the material.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Wet processing-washing is, in most cases, cleaning and separation of materials by use of water and mechanical forces. It is often followed by the removal of such impurities from raw materials as ores, minerals, sand, and gravels. The process commences by the introduction of the said raw materials in a wash plant and thorough soak with plenty of water. This initial saturation softens and loosens the unwanted materials, making them easier to separate from the valuable base material. Inside the wash plant, zones of high pressure and the whirling impact of paddles and jets alternately whip and beat the mixture, scouring away dirt, clays, silt, and all other contaminants. The continuous movement of water helps to further dislodge these impurities, allowing for a more thorough cleaning. By this point, this mixture has graduated to a cascade of hydrocyclones or comparable equipment in which centrifugal action predominates.

Request for a quote

OZZY CELIKTURK CO

Turkey

Wet wipes containing special solution processed on 180*140 mm non-woven fabric. 90 pcs in single pack and 24 pcs in single cartoon

Request for a quote

DIADAYS MEDIKAL ÜRÜNLER TICARET LIMITED ŞIRKETI

Turkey

Material: Non Woven 10 Gsm Spundbond Fabric Comfortable elastic, secures sleeves to wrist and elbow, one size fits most people Disposable sleeve is convenient and hygienic, elastic upper sleeves are dustproof to protect against spills, splashes or debris from daily work, protect your clothing from dirt and grime Widely use: These sleeves are great for food processing and wet work tasks, ideal for use by cleanrooms, electronics manufacturing areas, the packaging industry, cleaners, decorators and craftsmen, Package Include: 100 pcs / 50 pairs,

Request for a quoteResults for

Wet processing - Import exportNumber of results

15 ProductsCountries

Company type