- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting processes

Results for

Cutting processes - Import export

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Oxygen Cutting is the most widely used industrial thermal cutting process. After the metal material is heated to the ignition temperature with high heat obtained by burning in oxygen, the heated part is cut with pure oxygen gas jet. As Ramazan Aycan Inc., we can perform oxygen cutting from 35 mm to 150 mm with our new generation CNC oxygen cutting machines.

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

High efficiency and low cost in a short time in prototype works, More economical than machining, More flexible working opportunity in design, Production at lower costs in a short time without requiring molds in small quantities, Using the material in the most efficient and waste-free way in production, Allowing production without molds, Cutting No crushing of the material since there is no contact with the material during cutting, Burr-free and minimum roughness cutting process

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Technical Line Cutting Twist Metal Processing San. Tic. Ltd. Ltd. has created various designs since 2006. It has become indispensable for companies by adding innovations, different perspectives and various solutions to its designs with each passing year.

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Technical Line Cutting Twist Metal Processing San. Tic. Ltd. Şti. has made and continues to make significant investments in measurement, control and testing equipment to ensure the suitability of its products and the continuity of their total quality.

Request for a quote

PERGEL METAL

Turkey

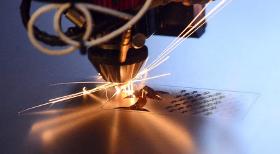

Laser cutting is carried out by special machines. All of the machines have the latest technological features. A fine and successful cutting technique is applied. It also provides the expected success in PVC cutting. Because the machine is strong; it applies a fast process in thick material cutting, aluminum, galvanized cuts. In particular, laser cutting, foil-coated cutting processes give more effective results than other materials. The burn trace is minimal and minimal. Our company is successful in this regard.

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

Laser cutting is a cutting method in which metal and non-metal materials with different material thicknesses are cut. The basis of the process is the directed, shaped and focused laser beam. By hitting the laser beam on the workpiece, the material is heated up to its melting or evaporation temperature

Request for a quote

NOVELTY STEEL

Turkey

Laser cutting is a cutting process which enables cutting metallic and non-metallic materials with different thicknesses for metal fabrication works. The cutting operation is based on a laser beam which is guided, formed, and bundled. While traditional metal cutting processes involve applying large-scale tools with enormous power to the metal, the laser beam completes its task without any direct contact to the work piece. This prevents any wearing, deformation and damage to the tool and the work piece. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

MAGMETT METALL INC.

Turkey

Introducing Aluminium Machining - Your Premier Provider of Proficient Profile Production and Processed Products At Aluminium Machining, we take pride in offering comprehensive services to our esteemed customers. Our expertise extends beyond profile production, as we also specialize in delivering top-notch processed or finished products utilizing the latest CNC and mechanical processing centers. With our state-of-the-art facilities, we guarantee precise cutting up to 5 mm, maintaining a remarkable tolerance of ± 0.1 mm. Our double-head saws enable us to effortlessly execute angled cuts ranging from 350mm to an impressive 12000mm. To further cater to your specific requirements, we possess the capability to conduct drilling, unloading, and die-cutting processes using eccentric presses. Additionally, our proficient team can seamlessly perform CNC milling and unloading processes, ensuring unparalleled precision and efficiency.

Request for a quote

SACFORM/AGMLINE

Turkey

Zigzag Servo Feeding System, Which Moves in Two Axes (X And Y), Is Specifically Preferred for Minimum Waste at Perimeter/Flake Cutting Processes. Its Body Structure Design Enables to Easily Adapt to All Kinds of Press Machines.

Request for a quote

PRO DESIGN

Turkey

Plywood cutting is the process of cutting and shaping layers of wood veneers to create plywood boards. Plywood is used in construction, furniture making, and various industrial applications. It offers strength and flexibility, allowing for intricate designs and structural stability. Plywood cutting is commonly used in carpentry and building projects.

Request for a quote

DAMS MACHINE

Turkey

It can cut sandwiches and hamburgers, flatbread, bagels, baguettes and similar products. It is used in the slicing (cutting) process of sandwich and hamburger breads before packaging. The slicing machine has wheels and can be taken anywhere easily. The chassis is completely chrome nickel. Used strip blade, easy to disassemble and install. The surfaces that the product comes into contact with are made of tape suitable for food. Product feeding is done manually.

Request for a quote

ALKIM PETROKIMYA

Turkey

It is qualified oil that is formulated with quality base oils obtained through modern refining processes. It is used in cutting and forming processes of metals containing or not containing iron in oil base formulations. It exhibits extra resistance against high pressure in cutting, broaching, penetrating, grinding and scratching processes through Sulphur chloride it contains.

Request for a quote

BACA MAKINE LTD.

Turkey

There are many different methods in the cutting process using lasers and bending which are used to cut or bend different materials into different shapes.

Request for a quote

BOSPORAS

Turkey

Deformations that are created by utilizing thermal cutting process causes metal materials to lose their flat form. The materials which are cut by a laser, plasma or oxygen cutter that utilize thermal process can become almost impossible to be in a desired flat form again. This is no longer an issue with the new generation leveler technology. Our new generation leveler touches almost every point of the sheet metal material and can smart process. That way, stressed material can be straightened.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin production is a process that requires precision and quality and an important part of this process is Band Saw Napkin and oll Cutting Machine. This machine increases efficiency and quality in napkin production by making high speed and sharp cuts. Band Saw Napkin Cutting Machine is one of the last stages of the product before reaching the end user, especially by ensuring that the napkins are cut in standard sizes and with smooth edges. Band Saw Napkin Cutting Machine is an industrial machine used to cut large napkin rolls in specified sizes. Using band saw technology, it cuts napkins at high speed and smoothly. This machine is suitable for both plain and patterned napkins and offers high cutting precision. High Cutting Speed and Precision: It performs the cutting process quickly and precisely. Flexible Production Capability: Ability to cut napkins of different sizes and patterns. Durable Structure: It has a robust structure suitable for continuous and intensive use.

Request for a quote

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

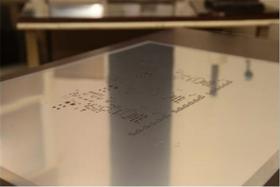

Due to the fact that punching and cutting processes are performed with molds in single-sided printed circuit board production, our company has established its own mold production facility. Printed circuit information from customers is converted into a format suitable for mold production machines in the CAD/CAM work preparation center and transmitted to the mold center via the local computer network. In this center, necessary mold drawings are made using this information, and molds are produced quickly and precisely on state-of-the-art machines.

Request for a quote

SAAFI FOR IMPORT AND EXPORT.

Turkey

* Reliable Operation with Microprocessor Control * 7 Segment Display Screen * Cutting, Coagulation and Bipolar Usage Modes * Different Audio Signals in Cutting and Coagulation Processes * Comfortable working with cautery pen or foot pedal * 160 Watt Output Power * Optional Argon Plasma Coagulation Compatibility

Request for a quote

SAAFI FOR IMPORT AND EXPORT.

Turkey

* Reliable Operation with Microprocessor Control * 7 Segment Display Screen * Cutting, Coagulation and Bipolar Usage Modes * Different Audio Signals in Cutting and Coagulation Processes * Comfortable working with cautery pen or foot pedal * 160 Watt Output Power * Optional Argon Plasma Coagulation Compatibility

Request for a quote

SAAFI FOR IMPORT AND EXPORT.

Turkey

* Reliable Operation with Microprocessor Control * 7 Segment Display Screen * Cutting, Coagulation and Bipolar Usage Modes * Spray and Contact Coagulation * REM (Return Electrode Monitoring) Function * Different Audio Signals in Cutting and Coagulation Processes * Comfortable working with cautery pen or foot pedal * 400 Watt Output Power * Optional Argon Plasma Coagulation Compatibility

Request for a quote

SAAFI FOR IMPORT AND EXPORT.

Turkey

* Reliable Operation with Microprocessor Control * 7 Segment Display Screen * Cutting, Coagulation and Bipolar Usage Modes * Different Audio Signals in Cutting and Coagulation Processes * Comfortable working with cautery pen or foot pedal * 200 Watt Output Power * Optional Argon Plasma Coagulation Compatibility

Request for a quote

ERDEMLER COOLING COMPANY

Turkey

As Erdemler Soğutma, we provide design, manufacturing, installation, aftersales service and maintenance services for our customers slaughterhouse and meat processing systems. We provide turnkey solutions in automation level. Modern cutting and meat processing systems are combining cold room systems for cattle, sheep, and chickens with automation technology. Our company gives importance to animal welfare, quality, safety, hygiene, and ergonomy by providing the highquality services. Our efficiency guarantees for competitive power to our customers.

Request for a quote

TEKNO KESIM

Turkey

custom and contracted manufacturer process for eva foam cutting about tool and medical industry and more. CNC foam cutting machine enables quick and cost-effective hole milling service. For mass production, cost-effective mold press cutting is also available. Soft urethane foam or harder polyethelene foam are also available. For custom cutting, harder polyethelene foam is used.

TEKNO KESIM

Turkey

we use standard EVA foam with a 75 Kg/m3 density. It has a 5–100 Shore A hardness. It is produced as a plate of 1000 x 1500 mm. Thickness of EVA plates starts from 1,5 mm and goes up to 38 mm which fits our EVA cutting process very well. As it has a high temperature tolerance, it can be molded by heat (thermo-form). EVA foam is resistant to heat starting from -40° C till + 90° C . It is a soft and flexible material. It can be with design on it. It is waterproof. It is antibacterial, free of hazerdous chemicals. It is available in various colors. As Tekno Kesim, we do EVA cutting for you by laser, cnc, waterjet or die cut for eva foam cutting. We have mentioned above the characteristics of EVA and due to these and the area you need to use, EVA cutting is prefered. As it has a very good suction ability, for sensitive items and electronic devices we make case inserts or box seperators by EVA cutting. It has many advantages like providing high protection and stylish appearance.

OZKOC HYDRAULIC MACHINE CO.

Turkey

Hydraulic press for deep drawing, forging, forming and cutting process

Request for a quote

YILMAZ MACHINE

Turkey

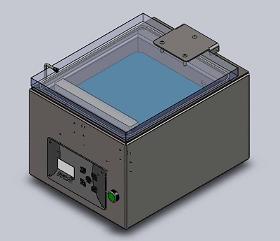

PRODUCT INFORMATION CPM 4150 is a CNC controlled machine which is specifically designed to machine any kind of composite panels, aluminum panels up to 4 mm, flexy panels, vs. commercially available. The machine is able to process the joint grooves on composite panels that are required for bending, drilling any type of holes, dimensioning the panels according to required sizes, etc. Equipped with the manual vacuum control system concentrating the suction on the required area 3 axis CNC automation system Solid steel construction of the body and dynamic performance Application of special cutting processes with YILMAZCAM software Z axis heat compensation system that adjusts the Z position of the cutter bit automatically considering to the elongation on the spindle because of the thermal changes.(Patented) High precision HSD spindle and internationally recognized components Minimum tool change time with 6 station automatic tool changer fixed on the gantry

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Automatic screwing of the steel reinforcement bar in the PVC profiles that comes out of PIM 6508 and PCC 6505 Profile Processing and Cutting Centers. Machine is fully compatible with the PIM 608 or PCC 6505 Processing & Cutting Centers Machine measure the length of the profile automatically and determine the number of the screw Automatic centering of PVC profiles at the screwing section by servo motor controller Screwing conveyorconveys PVC profiles that comes out from the Processing & Cutting Centers 2 pcs. of servo controlled screwing heads perform the screwing operation as per the program that is made by the operator Separately positioned screw feeding units ensure non-stop screwing operations Seamless screwing by the screw feeders positioned independently of screwing heads Technical support and trouble shooting can be done by remote connection by via VNC All error messages and system status information can be observed on the screen by using the HMI prog

Request for a quoteResults for

Cutting processes - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (5)

- Cutting - steels and metals (4)

- Medical Equipment (4)

- Medical and surgical instruments (3)

- Industrial sheet metal work (2)

- Blades for saws and cutting machines (2)

- Cutting - machine tools (1)

- Custom packaging (1)

- Metal structural work (1)

- Steels and metals - welding and brazing (1)

- Aluminium and aluminium alloys (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Cold rooms (1)

- Disposable medical and surgical articles (1)

- Foams, plastic (1)

- Glass, tempered (1)

- Import-export - oil (1)

- Mechanical surface treatment - machinery (1)

- Metal industrial presses (1)

- Point-of-sale advertising (1)