- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting processes

Results for

Cutting processes - Import export

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Oxygen Cutting is the most widely used industrial thermal cutting process. After the metal material is heated to the ignition temperature with high heat obtained by burning in oxygen, the heated part is cut with pure oxygen gas jet. As Ramazan Aycan Inc., we can perform oxygen cutting from 35 mm to 150 mm with our new generation CNC oxygen cutting machines.

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

High efficiency and low cost in a short time in prototype works, More economical than machining, More flexible working opportunity in design, Production at lower costs in a short time without requiring molds in small quantities, Using the material in the most efficient and waste-free way in production, Allowing production without molds, Cutting No crushing of the material since there is no contact with the material during cutting, Burr-free and minimum roughness cutting process

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Technical Line Cutting Twist Metal Processing San. Tic. Ltd. Ltd. has created various designs since 2006. It has become indispensable for companies by adding innovations, different perspectives and various solutions to its designs with each passing year.

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Technical Line Cutting Twist Metal Processing San. Tic. Ltd. Şti. has made and continues to make significant investments in measurement, control and testing equipment to ensure the suitability of its products and the continuity of their total quality.

Request for a quote

PERGEL METAL

Turkey

Laser cutting is carried out by special machines. All of the machines have the latest technological features. A fine and successful cutting technique is applied. It also provides the expected success in PVC cutting. Because the machine is strong; it applies a fast process in thick material cutting, aluminum, galvanized cuts. In particular, laser cutting, foil-coated cutting processes give more effective results than other materials. The burn trace is minimal and minimal. Our company is successful in this regard.

Request for a quote

MAGMETT METALL INC.

Turkey

Introducing Aluminium Machining - Your Premier Provider of Proficient Profile Production and Processed Products At Aluminium Machining, we take pride in offering comprehensive services to our esteemed customers. Our expertise extends beyond profile production, as we also specialize in delivering top-notch processed or finished products utilizing the latest CNC and mechanical processing centers. With our state-of-the-art facilities, we guarantee precise cutting up to 5 mm, maintaining a remarkable tolerance of ± 0.1 mm. Our double-head saws enable us to effortlessly execute angled cuts ranging from 350mm to an impressive 12000mm. To further cater to your specific requirements, we possess the capability to conduct drilling, unloading, and die-cutting processes using eccentric presses. Additionally, our proficient team can seamlessly perform CNC milling and unloading processes, ensuring unparalleled precision and efficiency.

Request for a quote

SACFORM/AGMLINE

Turkey

Zigzag Servo Feeding System, Which Moves in Two Axes (X And Y), Is Specifically Preferred for Minimum Waste at Perimeter/Flake Cutting Processes. Its Body Structure Design Enables to Easily Adapt to All Kinds of Press Machines.

Request for a quote

ALKIM PETROKIMYA

Turkey

It is qualified oil that is formulated with quality base oils obtained through modern refining processes. It is used in cutting and forming processes of metals containing or not containing iron in oil base formulations. It exhibits extra resistance against high pressure in cutting, broaching, penetrating, grinding and scratching processes through Sulphur chloride it contains.

Request for a quote

BOSPORAS

Turkey

Deformations that are created by utilizing thermal cutting process causes metal materials to lose their flat form. The materials which are cut by a laser, plasma or oxygen cutter that utilize thermal process can become almost impossible to be in a desired flat form again. This is no longer an issue with the new generation leveler technology. Our new generation leveler touches almost every point of the sheet metal material and can smart process. That way, stressed material can be straightened.

Request for a quote

BOSPORAS

Turkey

Deformations that are created by utilizing thermal cutting process causes metal materials to lose their flat form. The materials which are cut by a laser, plasma or oxygen cutter that utilize thermal process can become almost impossible to be in a desired flat form again. This is no longer an issue with the new generation leveler technology. Our new generation leveler touches almost every point of the sheet metal material and can smart process. That way, stressed material can be straightened.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin production is a process that requires precision and quality and an important part of this process is Band Saw Napkin and oll Cutting Machine. This machine increases efficiency and quality in napkin production by making high speed and sharp cuts. Band Saw Napkin Cutting Machine is one of the last stages of the product before reaching the end user, especially by ensuring that the napkins are cut in standard sizes and with smooth edges. Band Saw Napkin Cutting Machine is an industrial machine used to cut large napkin rolls in specified sizes. Using band saw technology, it cuts napkins at high speed and smoothly. This machine is suitable for both plain and patterned napkins and offers high cutting precision. High Cutting Speed and Precision: It performs the cutting process quickly and precisely. Flexible Production Capability: Ability to cut napkins of different sizes and patterns. Durable Structure: It has a robust structure suitable for continuous and intensive use.

Request for a quote

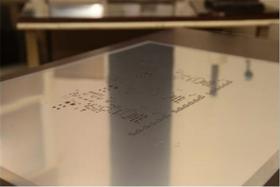

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

Due to the fact that punching and cutting processes are performed with molds in single-sided printed circuit board production, our company has established its own mold production facility. Printed circuit information from customers is converted into a format suitable for mold production machines in the CAD/CAM work preparation center and transmitted to the mold center via the local computer network. In this center, necessary mold drawings are made using this information, and molds are produced quickly and precisely on state-of-the-art machines.

Request for a quote

SAAFI FOR IMPORT AND EXPORT.

Turkey

* Reliable Operation with Microprocessor Control * 7 Segment Display Screen * Cutting, Coagulation and Bipolar Usage Modes * Spray and Contact Coagulation * REM (Return Electrode Monitoring) Function * Different Audio Signals in Cutting and Coagulation Processes * Comfortable working with cautery pen or foot pedal * 400 Watt Output Power * Optional Argon Plasma Coagulation Compatibility

Request for a quote

SAAFI FOR IMPORT AND EXPORT.

Turkey

* Reliable Operation with Microprocessor Control * 7 Segment Display Screen * Cutting, Coagulation and Bipolar Usage Modes * Different Audio Signals in Cutting and Coagulation Processes * Comfortable working with cautery pen or foot pedal * 160 Watt Output Power * Optional Argon Plasma Coagulation Compatibility

Request for a quote

SAAFI FOR IMPORT AND EXPORT.

Turkey

* Reliable Operation with Microprocessor Control * 7 Segment Display Screen * Cutting, Coagulation and Bipolar Usage Modes * Different Audio Signals in Cutting and Coagulation Processes * Comfortable working with cautery pen or foot pedal * 160 Watt Output Power * Optional Argon Plasma Coagulation Compatibility

Request for a quote

SAAFI FOR IMPORT AND EXPORT.

Turkey

* Reliable Operation with Microprocessor Control * 7 Segment Display Screen * Cutting, Coagulation and Bipolar Usage Modes * Different Audio Signals in Cutting and Coagulation Processes * Comfortable working with cautery pen or foot pedal * 200 Watt Output Power * Optional Argon Plasma Coagulation Compatibility

Request for a quote

TEKNO KESIM

Turkey

custom and contracted manufacturer process for eva foam cutting about tool and medical industry and more. CNC foam cutting machine enables quick and cost-effective hole milling service. For mass production, cost-effective mold press cutting is also available. Soft urethane foam or harder polyethelene foam are also available. For custom cutting, harder polyethelene foam is used.

Do you sell or make similar products?

Sign up to europages and have your products listed

OZKOC HYDRAULIC MACHINE CO.

Turkey

Hydraulic press for deep drawing, forging, forming and cutting process

Request for a quote

YILMAZ MACHINE

Turkey

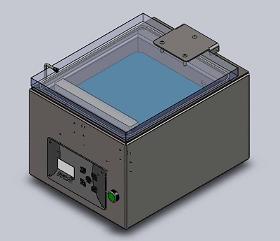

PRODUCT INFORMATION CPM 4150 is a CNC controlled machine which is specifically designed to machine any kind of composite panels, aluminum panels up to 4 mm, flexy panels, vs. commercially available. The machine is able to process the joint grooves on composite panels that are required for bending, drilling any type of holes, dimensioning the panels according to required sizes, etc. Equipped with the manual vacuum control system concentrating the suction on the required area 3 axis CNC automation system Solid steel construction of the body and dynamic performance Application of special cutting processes with YILMAZCAM software Z axis heat compensation system that adjusts the Z position of the cutter bit automatically considering to the elongation on the spindle because of the thermal changes.(Patented) High precision HSD spindle and internationally recognized components Minimum tool change time with 6 station automatic tool changer fixed on the gantry

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Automatic screwing of the steel reinforcement bar in the PVC profiles that comes out of PIM 6508 and PCC 6505 Profile Processing and Cutting Centers. Machine is fully compatible with the PIM 608 or PCC 6505 Processing & Cutting Centers Machine measure the length of the profile automatically and determine the number of the screw Automatic centering of PVC profiles at the screwing section by servo motor controller Screwing conveyorconveys PVC profiles that comes out from the Processing & Cutting Centers 2 pcs. of servo controlled screwing heads perform the screwing operation as per the program that is made by the operator Separately positioned screw feeding units ensure non-stop screwing operations Seamless screwing by the screw feeders positioned independently of screwing heads Technical support and trouble shooting can be done by remote connection by via VNC All error messages and system status information can be observed on the screen by using the HMI prog

Request for a quote

CMS GLASS MACHINERY

Turkey

Flat glass tempering furnace is designed to make heat resistant and stronger glass for the cut and processed glass. Flat glass, reflective glass, colored glass and hard-coated (Low-E) glass can be tempered. Glass tempering is performed in maximum quality.

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage systems -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Automatic cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts -Process counter -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage systems -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Automatic cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts -Process counter -Hassle-free performance

Request for a quote

DISPA MACHINE

Turkey

Double Column Bandsaws with linear guideways are ideal for MITRE cuts with different quantities. With the movement of the bow, it’s possible to cut between 90° and +45°. With height adjustment and hydraulic cutting, control allows the bow to go up over the material after the cut. All this process is controlled by a digital counter on the control panel and total duration for one cut decreases. Fixing the bow at any angle is controlled by the hydraulic brake system.

Request for a quoteResults for

Cutting processes - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (5)

- Medical Equipment (4)

- Medical and surgical instruments (3)

- Cutting - steels and metals (2)

- Blades for saws and cutting machines (2)

- Cutting - machine tools (1)

- Custom packaging (1)

- Aluminium and aluminium alloys (1)

- Foams, plastic (1)

- Glass, tempered (1)

- Import-export - oil (1)

- Mechanical surface treatment - machinery (1)

- Metal industrial presses (1)

- Screen printing on metal (1)

- Straightening - steels and metals (1)