- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyor belt accessories

Results for

Conveyor belt accessories - Import export

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

In industrial environments a combination feeding hopper and dosing belt conveyor is a frequently utilized system for regulated material feeding and dosage. Before raw materials or bulk materials are fed onto the belt conveyor they are first stored in the feeding hopper. In order to enable accurate material distribution and consistent dosing it guarantees a constant and continuous supply of materials to the dosing belt conveyor. Transporting and dosing materials at a regulated rate however is the job of the dosing belt conveyor. The technology is appropriate for batching mixing or processing operations that call for precise material dosing because it can control the conveyor belts speed and capacity to precisely dispense the required quantity of materials.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The PTT100 Track Stacker is an ultra-heavy-duty, versatile material-handling machine. Being a track-mounted stacker, it has unrivaled mobility and adaptability, suitable for large volumes of materials like aggregates, sand, gravel, and soil to move on difficult terrains. With the track-based system, the PTT100 can manage rough, uneven, or soft surfaces with ease; it is perfectly suited for mining, construction, and recycling industries. Be it an uneven job site or the need for efficient stockpiling in unapproachable areas, the machine is engineered for top performance in demanding conditions. Besides mobility, the PTT100 is designed to stack material efficiently for maximum storage space with minimum frequency of material handling. This saves immensely and enhances productivity in operations that require large-scale stockpiling. Coupled with other machinery, like crushers and conveyors, it becomes an integral part of a complete material handling system.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The PTT60 Track Stacker is a high-performance track-mounted stockpiling machine designed for conveying and stocking large volumes of material. Because of track-mounted mobility, this would be easy to maneuver into position and operate in difficult terrains. That makes the PTT60 ideal for industries such as construction, mining, recycling, and agriculture, where heavy material handling and stockpiling are at an all-time high. With the track system, this machine will have no problem operating on muddy, slippery, or uneven surfaces-it will be very manoeuvrable. The big stockpiling capacity translates to less number of operations, hence saving time on site. Besides the transport of materials, the PTT60 maximizes space utilization for the purpose of storage. The design allows higher and more accurate stacking to optimize space and reduce material handling costs. The machine can work with crushers, screens, and conveyors in conjunction with one another to enhance all operations.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Automatic Distribution Conveyor possessing a Shuttle Type design is a sophisticated material handling system applied in warehouses, distribution centers, and manufacturing facilities. This equipment is primarily engineered to automate the sorting and distribution of items along a conveyor line. Unlike the other systems, this system has a shuttle mechanism that runs across the entire width of the main conveyor, picking items up and transferring them transversely to specific offloading locations. It operates independently of the main conveyor and can handle the accurate transferring of items depending on their destination, size, weight, or any other parameter that needs to be considered. Incorporate this shuttle mechanism to improve the total efficiency and accuracy of the system in handling materials and automate the flow of goods through various processes from processing to shipping.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A specialized conveyor system called a telescopic radial stacker is used in material handling applications to stack bulk materials in radial stockpiles with efficiency. This equipment has an extendable and retractable telescopic boom that expands its reach and facilitates radial or circular material stacking. By utilizing the radial stacking feature the stacker can maximize storage capacity in a constrained footprint by forming stockpiles with a larger diameter.Effective bulk material management and storage is achieved through the widespread use of telescopic radial stackers in the mining construction and aggregate processing industries.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Skipper Conveyor is probably the most novel and technological advancement attributed to conveyor systems meant to streamline handling and distribution exhaustively used across a wide array of industries. Unlike the traditional style of conveyor systems, Skipper Conveyors are designed with diverter chutes or gates along the conveyor line. These chutes can be actuated to selectively direct materials to diverse discharge points or processing areas based on stipulated criteria such as size, weight, or destination. The capability of selectively distributing therefore makes Skipper Conveyors very useful; for instance, the separation and the direction of materials to many various stages of the production process are needed. An automated control system can also be integrated into the design of a Skipper Conveyor, which can control a diverter chute based on real-time data or according to an instruction that has already been programmed.

Request for a quote

WOCCOW

Turkey

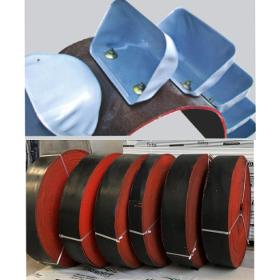

We are proud to manufacture unique, high-quality, durable elevator belt that meet customer requirements.

Request for a quote

WOCCOW

Turkey

We are proud to manufacture unique, high quality, durable conveyor belts that meet customer requiremenets. -Heavy Duty Conveyor Belt Width(cm): 500...1500 Lenght,Thickness,ClothType,Ply: OPTIONAL -Agrıculture Packing Machine Belts -Harvesting Machine Belts(potato, beet, carrot etc.)

Request for a quoteResults for

Conveyor belt accessories - Import exportNumber of results

10 ProductsCountries

Company type