- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high elasticity

Results for

High elasticity - Import export

IGUS® GMBH

Germany

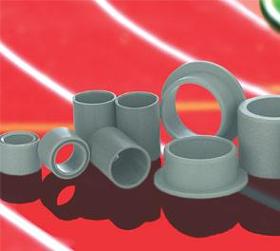

iglidur® B: Highest vibration dampening Vibration dampening is the salient feature of the iglidur® B bearings, which are also well-suited for edge loads at low forces. iglidur® B is available as cylindrical bearings and plain bearings with flange. Sound isolation Extremely high elasticity Sealing function possible

Request for a quote

IGUS® GMBH

Germany

iglidur® Z: The high-temperature material Extremely high compressive strength coupled with high elasticity enables iglidur® Z bearings to attain their prominent features in association with soft shafts, edge loads and impacts. The bearings are at the same time suitable for temperatures up to +250℃. iglidur® Z is available as cylindrical bearings and plain bearings with flange. Excellent wear resistance especially with high loads High thermic stability For extreme loads Also for high surface speeds Insensitive to edge loads

Request for a quote

IGUS® GMBH

Germany

iglidur® V400: Wear resistant at high temperatures High resistance to media and temperature. Highly wear-resistant bearing materials. Bearings for soft shafts and temperatures up to +200°C with low moisture absorption and excellent resistance to chemicals. iglidur® V400 is available as cylindrical bearings and plain bearings with flange. Extreme wear resistance with soft shafts and in high temperatures up to +200°C Chemical resistant High elasticity

Request for a quote

IGUS® GMBH

Germany

igubal® spherical balls W..M/I Standard spherical ball - dimensional series K and E in metric and inch dimensions igubal® spherical balls W..M/I igubal® spherical balls R...M Low cost spherical ball - dimensional series K and E in metric dimensions igubal® spherical balls R...M igubal® spherical balls X...M Spherical ball for high temperatures - dimensional series K and E in metric dimensions igubal® spherical balls X...M igubal® spherical balls J...M, mm Spherical ball for low humidity absorption - dimensional series K and E in metric dimensions igubal® spherical balls J...M, mm igubal® spherical balls J...M, large dimensions, mm Spherical ball for low humidity absorption - dimensional series K in metric dimensions igubal® spherical balls J...M, large dimensions, mm igubal® spherical balls JKM-GT split, mm Splitted spherical ball for low moisture absorption - Dimensional series K in metric dimensions igubal® spherical balls JKM-GT split, mm igubal® spherical balls UWEM Spherical ball for underwater applications - dimensional series E in metric dimensions igubal® spherical balls UWEM igubal® clearance-free balls J4VEM, mm Clearance-free spherical balls through camber, dimensional series E igubal® clearance-free balls J4VEM, mm igubal® spherical balls J4...M, mm Low priced spherical ball - dimensional series K and E in metric dimensions igubal® spherical balls J4...M, mm igubal®-spherical balls RN248..M, mm Detectable spherical ball - dimensional series K and E in metric dimensions igubal®-spherical balls RN248..M, mm Every iglidur® material possesses a series of special properties which account for its suitability for certain applications and requirements. Currently we offer you spherical balls made of iglidur® materials W300 (standard), J, J4, R, UW and X. igubal® spherical bearings application examples Special properties: maintenance-free dry operation Corrosion resistant High compressive strength High elasticity Very low weight Various materials Spherical balls - material properties iglidur® W300 (Standard) – very wear-resistant material iglidur® R cost-efficient and low coefficients of friction iglidur® X resistant to temperature and chemicals iglidur® J low coefficients of friction and low humidity absorption iglidur® UW suited for underwater applications Tolerances Maintenance-free igubal® spherical balls are designed with a tolerance in the inner diameter according to E10. The shaft should have a tolerance between h6 and h9. When to use it? When maintenance-free materials are required When components of the dimensional series E and K should be used When different iglidur® materials should be tested When high compressive strength is required When high elasticity is required When not to use? When temperatures above +250°C prevail When dimensions over 50 mm are needed When rotation speeds in excess of 0,5 m/s should be implemented igubal® spherical balls W..M/I Standard spherical ball - dimensional series K and E in metric and inch dimensions igubal® spherical balls W..M/I igubal® spherical balls R...M Low cost spherical ball - dimensional series K and E in metric dimensions igubal® spherical balls R...M igubal® spherical balls X...M Spherical ball for high temperatures - dimensional series K and E in metric dimensions igubal® spherical balls X...M igubal® spherical balls J...M, mm Spherical ball for low humidity absorption - dimensional series K and E in metric dimensions igubal® spherical balls J...M, mm igubal® spherical balls J...M, large dimensions, mm Spherical ball for low humidity absorption - dimensional series K in metric dimensions igubal® spherical balls J...M, large dimensions, mm igubal® spherical balls JKM-GT split, mm Splitted spherical ball for low moisture absorption - Dimensional series K in metric dimensions igubal® spherical balls JKM-GT split, mm igubal® spherical balls UWEM Spherical ball for underwater applications - dimensional series E in metric dimensions igubal® spherical balls UWEM igubal® clearance-free balls J4VEM, mm Clearance-free spherical balls through camber, dimensional series E igubal® clearance-free balls J4VEM, mm igubal® spherical balls J4...M, mm Low priced spherical ball - dimensional series K and E in metric dimensions igubal® spherical balls J4...M, mm igubal®-spherical balls RN248..M, mm Detectable spherical ball - dimensional series K and E in metric dimensions igubal®-spherical balls RN248..M, mm

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

Back in 1978, Ralph Schöpp KG was the first manufacturer to produce a smooth velour surface for an indoor tennis court - since then, more than 2000 velour courts have been installed. The experience we have gained over this period enables us to offer you a truly perfect product today - SCHÖPP®-Classic. A yarn weight of 1000 g/sqm and a pile density of 244,000 pimples/sqm guarantee a surface quality that can no longer be surpassed in terms of sports functionality and durability. sporty, fast ball bounce in the comfort version, high rubber elasticity with good rating comfort life expectancy of approx. 15 years depending on the intensity of use elegant, cosy velour look

Request for a quote

RHIMEX.COM

Netherlands

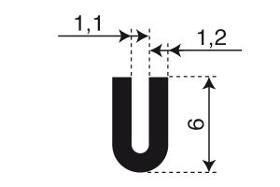

Uprofiles are suitable as a sealing profile, edge finishing, clamping profile or as a bumper. High elasticity protects against tearing UV and ozone resistant Long lifespan

Request for a quote

RHIMEX.COM

Netherlands

Tprofiles are specially made to seal gaps or crevices, of doors, hatches, windows or with sheet material. High elasticity protects against tearing EPDM and TPE UV and ozone resistant Widely used in ship and bodywork construction

Request for a quote

RHIMEX.COM

Netherlands

Glass trolley profiles are used for transporting glass plates or finishing windows and doors. Buffer profiles can be used as a stop buffer or as an equipment leg. In EPDM excellent UV and ozone resistant High elasticity Resistant to tears and perforations

Request for a quote

POLIFILM

Belarus

provides a connection point with a rough and fleecy surface, preventing displacement of the glued ones; has high flexibility and elasticity for fixing rough surfaces; is easy to use, environmentally friendly and easy to dispose of; connects elements together, keeping their fragile parts intact. for gluing materials that are subject to heavy loads; for laying floor coverings; for temporary restoration work; for decoration of exhibition premises; for installation of materials that must remain motionless even under mechanical influence; for gluing various rolled materials during their production, including on continuous conveyors. Quantity pcs. 64

Request for a quote

SYSKOMP GMBH - EMICO

Germany

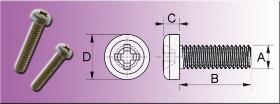

Material: PEEK Colour: light brown - Temperature: max. 180°C - High-strength and excellent form stability - High modulus of elasticity and excellent creep resistance - Resistant to many chemicals - Flammability rating: UL94 V0 - Further PEEK products: series 280 to series 285

Request for a quote

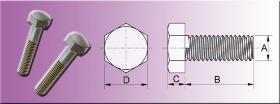

SYSKOMP GMBH - EMICO

Germany

Material: PEEK Colour: light brown - Temperature: max. 180°C - High-strength and excellent form stability - High modulus of elasticity and excellent creep resistance - Resistant to many chemicals - Flammability rating: UL94 V0 - Further PEEK products: series 280 to series 285 and 302

Request for a quote

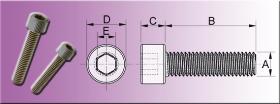

SYSKOMP GMBH - EMICO

Germany

Material: PEEK Colour: light brown - Temperature: max. 180°C - High-strength and excellent form stability - High modulus of elasticity and excellent creep resistance - Resistant to many chemicals - Flammability rating: UL94 V0 - Further PEEK products: series 280 to series 285

Request for a quote

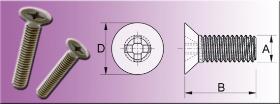

SYSKOMP GMBH - EMICO

Germany

Material: PEEK Colour: light brown - Temperature: max. 180°C - High-strength and excellent form stability - High modulus of elasticity and excellent creep resistance - Resistant to many chemicals - Flammability rating: UL94 V0 - Further PEEK products: series 280 to series 285

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Material: PEEK Colour: light brown - Temperature: max. 180°C - High-strength and excellent form stability - High modulus of elasticity and excellent creep resistance - Resistant to many chemicals - Flammability rating: UL94 V0 - Further PEEK products: series 280 to series 285

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Structure of germanBelt® steel cord conveyor belts Steel cord reinforcement: The standard steel cords have been hot-dip galvanised and have diameters from 2.6 to 12.8 mm. They are manufactured in 7x7 or 7x19 designs (other designs are possible). Their design allows good rubber saturation and distribution. Skim layers: A special chemical process provides excellent rubber/metal adhesion in the steel cord conveyor belt. The design of the steel cords leads to outstanding adhesion that surpasses any standards. Good rubber saturation and high adhesion on each cord provide germanBelt® steel cord conveyor belts with extraordinarily high longevity. Covers: The covers’ abrasion resistance, tensile strength and elongation value depend on the quality of the chosen combination of covers of the steel cord conveyor belt. Lateral reinforcements: The steel cord conveyor belts’ reinforcements consist of lateral steel cords with very high elasticity, or of textile fabric. The lateral reinforcements are worked into the carcass or the cover.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBond® 4kP CFC-free Applications: Long lasting elastic adhesion with high firmness of PVC and Polyurethane for joining conveyor belts, lining reservoirs etc. By means of a one- or a two component(s) adhesive. As well as adhesion of various products made of plastic, rubber, textile, leather, wood and similar materials, together and one to another. By adding the binding material germanBond Hardener RFE, the gluing firmness, the resistance against heat, emollients and dampness and the adherence can be significantly improved. Specifications: Colour: colourless Hardness: germanBond® RFE Cleaner/Diluent: germanBond® CLP Flash-off time: approx. 2 min (at 20°C) Application quantity: ca. 150 g/m² per coat Packing units: 0.65 kg - 4.0 kg Downloads: Safety Data Sheet germanBond® 4kP - English [PDF] Safety Data Sheet Hardener germanBond® RFE - English [PDF] Application Instructions germanBond® 4kP - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBond® 4kR CFC-free Applications: 2 component contact adhesive free of chlorinated hydrocarbon and aromates for cold bonding of conveyor rubber belts, rubber linings, friction laggings for pulleys and rollers as well as for the permanent-elastic and high-strength bonding of rubber, fabrics, leather, polyurethane and other materials. Specifications: Colour: black Hardener: germanBond® RE Cleaner/Diluent: germanBond® CLR Flash-off time: approx. 10 min (at 20°C) Application quantity: approx. 150 g/m² per coat Packing units: 0.65 kg - 4.0 kg - 24.0 kg - 170.0 kg Downloads: Safety Data Sheet germanBond® 4kR - English [PDF] Safety Data Sheet germanBond® RE - English [PDF] Application Instructions germanBond® 4kR - English [PDF]

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAXI SA

Belgium

The elastic track application "Railflex" for crossing levels is characterized by a complete rail insulation carried out thaks to an application on continuous elastic boot and an elastomer rail clamps fixing. Therefore, the direct contact between the rail and its steel support is avoided. Main assets of elastic material: -Very high ability to support loads -Very high ability to put power into store and to clear it -Excellent tiredness endurance within the framework of repeated use -High strength to impacts, even under negative temperatures -Good strength to chemical agents and humidity -Very high strength to cuts and abrasion -Excellent maintenance of the specifications during time (not much ageing) The Railflex system is acting bith dynamically and kinematically. 1. DYNAMIC : The vibrations due to the wheel rolling on the rail are filtered by the elastomer supports and their transmission to foundations is reduced thanks to the absorbing effect of the insulating material. The foundation is less in demand, its deterioration is slowed or stopped. Moreover, as the rail is supported elastically, the dynamic impact ratio (wheel on rail) is lowered, the wheel is less "agressive" towards rail which lead to a reduction of the wheels and rails wear. 2. KINEMATIC : When a rail fixed accordingly the Railflex system is subjected to a transverse use at rail top level, the rail moves a little bit aside while it bows down lightly. This rails over-gap changes the kinematic conditions of the naturally curved axle's position effect and a more energetic return to the middle of the track in straight line. These effects are also very favorable to the reduction of wheels and rail wear. Adjustment of the « RAILFLEX » system to road crossing. Description : - The system described hereafter offers the following assets : quickness of implementation thanks to a maximum prefabrication ; quick implementation of railroad and road traffic ; easiness of rail substitution without road destruction ; no maintenance. - The rails are put down on 2 steel gutters. - The 2 steel gutters are linked together through streamlines. - The "gutters/streamlines" set makes up a stiff frame of which the length is variable according to the needs. - A wire grill is welded between the 2 gutters inner faces as well as the outside in order to set up a framework for the material which will be implemented for the finishing works of the level crossing (concrete, sand,...). - The metallic frames are protected against rust. - The frames are put in the gutters on a reinforced elastic boot and are fixed with elastomer rail clamps. Conceivable options : - According to the customers requests, an electric insulation of the 2 tracks can be considered. - The system can be planned for straight sections as well as curves. In this case, a guard rail can be intended for the faint radius curves. The guard rail is also completely separated from the metallic frame, so from the foundation through supports and elastomer washers. - The system can be implemented for different types of rails. - The gap between the rail and the gutters inner faces is filled as following : in the gutter's bottom, a small grading gravel is poured on a 80 cm height. The higher volume is filled with a suitable industrial foam. If necessary, a water harvest device at the level crossings both ends can be suggested. The both ends can be adapted to the layout of the premises. At the level crossings both ends, a protection device against the coupler is planned. Application : - The frames are put down on the bottom of tracks form. - The frames are leveled and brung into line with the track. - The set is concreted (quick setting concrete)

Request for a quoteResults for

High elasticity - Import exportNumber of results

19 ProductsCountries

Company type