- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pet resin

Results for

Pet resin - Import export

ISOVOLTA AG

Austria

Conductofol consists of calcined mica paper impregnated with resin and a PET-or PI-film carrier. It is used for Insulation of rectangular copper conductors of low and high voltage coils.

Request for a quote

GM CHEMICAL CO., LTD

China

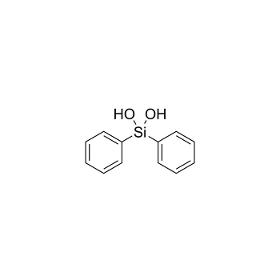

Product Identification Chemical name: Diphenylsilanediol Synonyms: Dihydroxydiphenylsilane, Diphenyldihydroxysilane CAS No.: 947-42-2 Molecular formula: C12H12O2Si Molecular weight: 216.31 Melting point: 135-150 ℃ Specification Appearance: White powder Purity: 98.00%min by GC Volatile: 0.10%max Package Regular Packing: N.W 25kg/plastic drum Sample Packing: 0.1kg-1kg plastic bottle Transportation Information Classification: Class 4.1 dangerous goods UN 1325 PG II HS Code: 2931900090 Status & Application Status: Commercial available Application: Used as a silicone rubber structure control agent to reduce the structuring phenomenon of silicone rubber and improve the processing performance of silicone rubber; it can be used to synthesize phenyl silicone oil, phenyl silicone resin, phenyl silicone rubber Chemicalbook, etc.; It can be used as modified intermediates of polyurethane resin, epoxy resin, acrylic resin, PP, PET, PE, etc.

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

Green Polyester film, single coated with a rubber resin pressure sensitive adhesive. APPLICATIONS Masking in powder coating applications. Protects large areas of circuit boards from chemicals fumes or splashes. Masking of circuit boards during solder stripping and nickel/gold plating of contact fingers. PRODUCT BENEFITS Resists baking temperatures of 170°C to 190°C during 20min. Operating temperature range: ‐30°C to 130°C. Eliminates silicone contamination and need for PCB cleaning solvents. Easy application and removal. Non‐silicone adhesive removes cleanly. Good adhesion to substrate. Excellent conformability.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The MRS extruder processes undried PET bottle flake without any pre-treatment directly into pellets. The polymer melt is intensively and rapidly exchanged in the multiple screw section of the extruder. The huge surface area is exchanged at an unparalleled rate so that even with a moderate vacuum level of 25 to 40 mbar in the degassing section, contaminants are efficiently evaporated out of the melt. A letter of Non Objection (LNO) from the FDA underlines the decontamination efficiency. If, in order to boost the intrinsic viscosity (IV) a downstream solid state polymerisation system (SSP) is used, this can be specified far shorter than otherwise necessary as the extruder has already carried out the decontamination of the bottle flakes. The end product is of especially high quality with regard to transparency and yellowness.

Request for a quote

CYPET TECHNOLOGIES

Cyprus

CYPET single stage injection stretch blow molding machines automatically produce finished blown containers directly from PET resin. The system utilizes CYPET’s patented technology that uses only two stations, one for injection molding the PET preforms, and the second to stretch blow mold the PET containers. The machines have unparalleled flexibility, allowing production of containers ranging from 20ml up to 120Ltr, with up to 400 mm neck diameter. Highly optimized, energy-saving servo-hydraulic technology as well as the use of an air recovery system as standard, reduces energy consumption by up to 40% (0.31kWh/kg of finished bottles). The machine’s generous clamping force and platen size, allows molds with higher cavities achieving higher output with less investment compared to conventional technologies. The machine can mold PET water bottles, jerrycans, liquor miniatures, wide mouth jars, large drums, pressurized containers. Handles can be incorporated as one piece with the bottle.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pet resin - Import exportNumber of results

5 ProductsCountries

Company type