- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- moving materials

Results for

Moving materials - Import export

PAWONEX

Poland

The classic winter smurfette is a women's hat that suits any occasion. This cut is one of the most fashionable on the market and is eagerly worn by girls and mature women. A hat in this style makes you feel really fashionable and is also very comfortable. It cannot also be denied that her appearance attracts the attention of both sexes. We encourage you to take an interest in the Aurora hat, which is a representative of the Smurfette cut. It is a warm winter hat made of yarn, decorated with an elegant ribbon with a crown Smurfette winter hats – what does this name come from? If you know classic cartoons well, you surely remember what hats the Smurfs wore. They are very characteristic due to the excess material that moved to the back. The women's Smurfette hat is styled after cartoon hats and it must be admitted that this name fits them perfectly. The Smurfette hat is a modern synonym of high quality and unique style, appreciated by women all over the world.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product introduction: 1.During the period of pregnancy and lactation,most of mothers are easy to leak milk. Breast pads help to absorb milk preventing leakage and keep the breast dry. 2.Replace after feeding or pumping session to reduce skin irritation risk and minimize sour milk odor. Product Function: 1.Secure day and night; 2.Feel dry even with heavy milk flowing; 3. Keep skin soft and safe; 4.Tapes keep pad without any moving; Main materials: 1.Fluff pulp+SAP(Jel); 2.Non-woven fabric; 3.Tissue paper; 4.Breathable waterproof film; 5.Adhesive tape; 6.Release paper; Main Design 1.Unique leakage on sides; 2.Special absorbent core; 3.Additional leakage barriers; 4.Secure hold firmly; 5. 3D design makes fit perfectly

Request for a quote

FINDEVA AG

Switzerland

Properties Rated frequency 6,500 – 23,000 rpm Centrifugal force 600 – 6,060 N Continuously variable Can be used up to 100°C Resistant to extreme environmental conditions Field of application Emptying of bunkers Screen filters Vibrating tables Preventing adhesions in pipelines and silos Transporting of fine powders Moving of bulk material

Request for a quote

SAMSYS GMBH

Germany

ar feeder for special profiles wanted ? To extend the MULTI 3000 to the bar feeder for special profiles, the Uni-erector can be mounted optionally. It enables the erection of rectangular profiles and special profiles for further transport to connected machine tools. Thus a smooth reloading process is possible. By simply setting a parameter, the erector can be selected or deselected. This enables a quick changeover from round material to a special profile. By deactivating it, the bar loader can load round or hexagonal material as normal. While with activated parameter the bar feeder will load the special or rectangular profile while the reloader is erecting. The use of square material is also optionally possible. The erector consists of two opposite rollers. To erect the material, these rollers move together during reloading. When the bar is threaded into the machine tool, the rollers open again. The distance between the rollers can be easily adjusted.

Request for a quote

BÜRKLE GMBH

Germany

The bucket is made entirely of high-gloss polished stainless steel. The smooth surface of the stainless steel bucket makes it easy to clean. The rounded, movable handle makes it comfortable to move the bucket. The laboratory bucket is suitable for moving liquids and bulk materials properly, especially in the chemical, pharmaceutical or cosmetic industries, and in the food and animal feed industries.

Request for a quote

NOVELTY STEEL

Turkey

A screw feeder is primarily designed for handling very low-tonnage outputs, with a critical requirement for positive and controlled material discharge. This type of feeder offers the advantage of easy enclosure, making it effective at preventing the release of dust. Consequently, it allows for a sealed hopper and chute arrangement from the hopper to the delivery point. The basic structure of a screw feeder includes a helical screw that rotates below the hopper outlet and is driven by an external power source. The screw can have a fixed pitch or a variable pitch with smaller spacings in the rear and gradual increases in pitch towards the discharge end. This design ensures that the material moves efficiently within the rear portion of the hopper. Novelty Structures supplies various type of Feeders for Mineral Processing Plants. * Belt Feeders * Screw Feeders * Apron Feeders * Rotary Table Feeders

Request for a quote

FINDEVA AG

Switzerland

Properties Lubrication-free Low noise level Strong vibration by means of high speed and eccentric working torques Rated frequency 14,000 – 37,000 rpm Centrifugal force 750 – 5,700 N Continuously variable Can be used up to 150°C Resistant to extreme environmental conditions Field of application For foodstuffs and pharmaceuticals, complies with FDA specification Emptying of bunkers Screen filters Vibrating tables Preventing adhesion in pipelines and silos Transporting of fine powders Moving of bulk materials

Request for a quote

FINDEVA AG

Switzerland

Properties Lubrication-free Low noise level Strong vibration by means of high speed and eccentric working torques Rated frequency 6,000 – 46,000 rpm Centrifugal force 130 – 12,000 N Continuously variable Can be used up to 150°C Resistant to extreme environmental conditions Field of application Emptying of bunkers Screen filters Vibrating tables Preventing adhesion in pipelines and silos Transporting of fine powders Moving of bulk materials

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Magnetic chip conveyors transfer wet or dry ferrous scrap without carryover. PRAB’s magnetic chip conveyors effectively transfer wet or dry ferrous chips, stamping slugs, turnings, parts or die scrap without carryover. This scrap conveyor system moves material with the aid of permanent ceramic magnets located under a stainless-steel slider bed. An oil reservoir in the base of the conveyor self-lubricates the chain for quiet performance and low maintenance of this scrap handling system.

Request for a quote

TOMECH SOLUTIONS

Romania

Feeders are devices used to regulate and control the flow of bulk materials from a storage container or hopper to downstream processes or equipment. They play a vital role in ensuring a steady and controlled supply of material, enhancing the efficiency and productivity of material handling systems. Vibrating feeders are a type of feeder that utilizes vibrations to move materials along a trough or tube. Vibrating feeders are commonly used in industries such as mining, aggregate processing, and pharmaceuticals due to their ability to handle a wide range of materials and feed rates while minimizing spillage and dust emissions. We specialize in feeder design services, offering tailored solutions to optimize material flow, feed rate, and system performance. Our expertise encompasses the design, selection of feeder type, and integration of feeding equipment into material handling systems to meet the specific requirements of our clients and enhance their operational efficiency.

Request for a quote

RECORD-TRANS

Belgium

At Record-Trans, we specialize in seamless transport services between Belgium and the Ruhr area, Germany—Europe's industrial heartland. Whether you're moving raw materials, finished goods, or oversized items, we ensure efficient and punctual deliveries across this vital economic region. With our experienced drivers and modern fleet, we navigate the complexities of cross-border logistics, offering tailored solutions for both FTL and LTL shipments. For dependable, timely, and cost-effective transport to and from the Ruhr, Record-Trans is your trusted partner.

Request for a quote

AUROMAK MAKINA

Turkey

The tunnel-type hot water and multi-purpose washing, rinsing, drying and lubricating system is an effective cleaning and treatment method of ten used on a large scale in industrial production processes. This system is located inside a tunnel where materials move automatically on a convey or belt.

Request for a quote

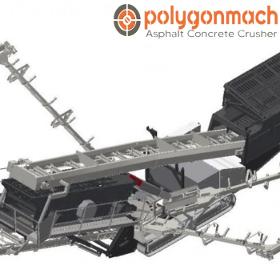

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Vibrating horizontal and sloping screens are types of screening equipment commonly used in various industries to sort, classify, and separate materials based on size. Horizontal screens are designed with a level screening deck that vibrates horizontally, allowing materials to move smoothly across the screen surface. This horizontal movement helps in effectively screening materials, separating finer particles from larger ones. On the other hand, sloping screens are inclined at an angle, providing a sloped screening surface that allows materials to cascade down the screen. The sloping motion facilitates the movement of materials along the screen deck, aiding in the separation process based on size as particles pass through the screen apertures. Both vibrating horizontal and sloping screens operate using vibrating mechanisms that create controlled vibrations to move materials along the screen decks.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Vibrating horizontal and sloping screens are types of screening equipment commonly used in various industries to sort, classify, and separate materials based on size. Horizontal screens are designed with a level screening deck that vibrates horizontally, allowing materials to move smoothly across the screen surface. This horizontal movement helps in effectively screening materials, separating finer particles from larger ones. On the other hand, sloping screens are inclined at an angle, providing a sloped screening surface that allows materials to cascade down the screen. The sloping motion facilitates the movement of materials along the screen deck, aiding in the separation process based on size as particles pass through the screen apertures. Both vibrating horizontal and sloping screens operate using vibrating mechanisms that create controlled vibrations to move materials along the screen decks.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Welded structure from steel sheets. They are mounted on the shaft in the housing two discs to which clamp hammers are attached. Crusher inside it is lined with carpet, in the lower part with grates, and a gap between them allows the crushed material to move downwards at an appropriate level granulation. The hammers, grate and carpets are made of material abrasion resistant. The hammers on the discs are mounted oscillatingly.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Stonebox Hopper is a kind of storage container that is frequently used to store and move bulk materials including stones aggregates and other hard materials in the mining quarrying and construction industries. These hoppers are made especially to efficiently handle abrasive and heavy materials. The word Stonebox suggests that it is ideal for working with heavy rough stones or comparable materials. For the materials kept inside of them to cause impact and abrasion stonebox hoppers are usually built with a sturdy construction. Their role in overseeing the handling of bulk material storage and transportation in industrial processes is crucial. In real-world settings Stonebox Hoppers serve as a loading and storing unit for the orderly transfer of materials onto conveyors or downstream processing machinery. A consistent flow of materials is ensured onto the conveyor system for additional handling by the features built into these hoppers that make loading and unloading easier.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Vibrating, inclined screens are specialized equipment used in various industries for the efficient screening and separation of materials based on size. These screens are designed with a sloped deck that allows materials to move along the surface while being subjected to vibrating motions. The vibrating motion, typically generated by a motor, causes the material to stratify and separate according to size as it moves down the inclined surface. This screening process helps to classify materials into different fractions based on particle size, allowing for the separation of finer particles from coarser ones. Vibrating, inclined screens are commonly employed in applications where precise material separation is essential, such as in mining, aggregate production, and recycling operations.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A rotary dryer is described as an industrial drying device or equipment used to dry an item through the introduction of heat. Such kinds of equipment include a big, rotating, slightly tilted cylindrical drum that allows materials to move through it as it rotates. Feeding is done by the supply of material to be dried into the dryer; upon the rotation of the drum, material gets lifted by internal flights and cascades through a stream of hot air. This ensures efficient heat transfer for moisture removal. Such wide use of rotary dryers is occasioned by their capacity to process vast amounts of material and, at the same time, be flexible enough to be used in processing a variety of different materials. Be it the drying of minerals, chemicals, or even agricultural products, a rotary dryer efficiently gives a material the required amount of moisture removal so that it becomes prepared for additional treatment or handling, storage, or transport.

Request for a quote

RECORD-TRANS

Belgium

When it comes to transporting long or oversized materials like steel tubes, beams, or plates, Record-Trans has the expertise and equipment to get the job done right. Our fleet is equipped to handle even the most challenging loads, ensuring safe and secure delivery, no matter the length or weight. From construction materials to industrial steel, we provide specialized transport solutions that accommodate your unique needs, maintaining strict safety standards and efficient handling. Trust Record-Trans to move your long materials reliably and on time, every time.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Fine material washers, otherwise known as spiral classificators or screw washers, are typically utilized in the aggregate and mining industries to clean fine materials such as sand, gravel, or even crushed stone. This machine contains a rotating screw shaft enclosed in a trough that conveys a water/material mixture. While the materials are being moved along the screw shaft, the agitating and rotating action of the screw enables the washing and separation of the finer particles from the coarser ones. Water is introduced at the same time into the system to aid washing for the removal of impurities, then leaving fine, drier materials that are ready for further processing or stockpiling. Fine material washers are used to process fine materials into high-quality and pure materials that can be applied in construction and in the production of concrete, among other uses.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The PTT80 Track Stacker is a robust, track-mounted material handling equipment which moves and stacks bulk materials like soils, sands, gravels, and other kinds of aggregates in an efficient manner. With robustly designed and advanced engineering, the PTT80 is designed to undertake heavy-duty work in industries such as construction, mining, recycling, and others. What distinguishes the PTT80 from competition on the market is that it has a track-mounted system, enabling higher mobility and the ability to work on uneven surfaces. The unit ensures complete accuracy for stockpiling material efficiently on uneven, rough, or soft surfaces without further assistance or use of any complementary machinery. Besides its maneuverability, the PTT80 is capable of stacking heights that allow the operator to maximize their available storage space and reduce material handling frequency. In that respect, the machine is ideal for projects where time and space are at a premium.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A track stacker is versatile, mobile equipment mainly utilized in the bulk material handling industry. With their tracked ability to move, these stackers are designed to move and stack materials such as soil, sand, aggregates, and other bulk goods. They find their most important applications in operations that call for efficient stockpiling and accurate placement in large quantities. Their tracked mobility enables them to operate in areas that might not be accessible for conventional wheeled stackers; hence, they become ideal for mining, construction, and recycling sites. These machines can deal not only with huge volumes of materials at higher speeds but the precision with which they work makes them very critical in the workflow in order to optimize storage and processing space.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Wobbler Feeder is a very important feeder and pre-screening equipment in the mining and aggregate industries, especially prior to the primary crusher. A Wobbler Feeder differs from conventional feeders in that it is capable of handling wet, sticky, or clay-bound materials through an innovative system of elliptical bars mounted on eccentric shafts. These bars rotate and wobble to produce mild agitation, keeping the flow under control. The effect helps to loosen lumpy material and break sticky material into smaller lumps to ensure free movement of material in the process plant without obstructions or delays. Probably the most important feature of a Wobbler Feeder is its capability of processing material, which, for other types of feeders, is considered being of considerable handicap. The elliptical bar of Wobbler Feeders oscillates and serves to sharply separate the material, ensuring that only the wanted size and type of materials get to move on to the crusher.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Stonebox Hopper is a kind of storage container that is frequently used to store and move bulk materials including stones aggregates and other hard materials in the mining quarrying and construction industries. These hoppers are made especially to efficiently handle abrasive and heavy materials. The word Stonebox suggests that it is ideal for working with heavy rough stones or comparable materials. For the materials kept inside of them to cause impact and abrasion stonebox hoppers are usually built with a sturdy construction. Their role in overseeing the handling of bulk material storage and transportation in industrial processes is crucial. In real-world settings Stonebox Hoppers serve as a loading and storing unit for the orderly transfer of materials onto conveyors or downstream processing machinery. A consistent flow of materials is ensured onto the conveyor system for additional handling by the features built into these hoppers that make loading and unloading easier.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Vibrating, inclined screens are specialized equipment used in various industries for the efficient screening and separation of materials based on size. These screens are designed with a sloped deck that allows materials to move along the surface while being subjected to vibrating motions. The vibrating motion, typically generated by a motor, causes the material to stratify and separate according to size as it moves down the inclined surface. This screening process helps to classify materials into different fractions based on particle size, allowing for the separation of finer particles from coarser ones. Vibrating, inclined screens are commonly employed in applications where precise material separation is essential, such as in mining, aggregate production, and recycling operations. These screens are effective in removing unwanted materials, maximizing screening efficiency, and improving the quality of the final product.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Rotary Dryer? A rotary dryer is described as an industrial drying device or equipment used to dry an item through the introduction of heat. Such kinds of equipment include a big, rotating, slightly tilted cylindrical drum that allows materials to move through it as it rotates. Feeding is done by the supply of material to be dried into the dryer; upon the rotation of the drum, material gets lifted by internal flights and cascades through a stream of hot air. This ensures efficient heat transfer for moisture removal. Such wide use of rotary dryers is occasioned by their capacity to process vast amounts of material and, at the same time, be flexible enough to be used in processing a variety of different materials. Be it the drying of minerals, chemicals, or even agricultural products, a rotary dryer efficiently gives a material the required amount of moisture removal so that it becomes prepared for additional treatment or handling, storage, or transport.

Request for a quoteResults for

Moving materials - Import exportNumber of results

56 ProductsCountries

Company type

Category

- Concrete preparing - machinery and equipment (7)

- Crushing and grinding machinery (3)

- Bags (2)

- Electronic components (2)

- Engineering - industrial consultants (2)

- Goods handling systems, continuous (2)

- Goods transport (2)

- Industrial washing facilities (2)

- Lifting equipment (2)

- Metals - Machines & Equipment (2)

- Mining and quarrying - machinery and equipment (2)

- Sawing machine tools (2)

- Stackers (2)

- Ambulance and funeral transport (1)

- Baby-care products (1)

- Broaching - steels and metals (1)

- Buckets and grabs, crane (1)

- Bulk materials for construction (1)

- Compactors and crushers (1)

- Compensators (1)