- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stacker- used

Results for

Stacker- used - Import export

FERPLAST SNC

Italy

HYDRAULIC DRUMS TILTER MOD. DA-FP 45 for metal or plastic drums. The new drums-tilter mod. DA-FP 45 is equipped with hook and safety band and is suitable for lifting, transporting, emptying both 210 liter metal and plastic drums. Equipped with hydraulic system with pedal or rudder drive, push handles, angular transmission with practical handwheel for drum rotation, hook and safety band to lock the drum, nylon wheels with high smoothness and brake. The lifter can also be used as a stacker for stacking or for positioning the drums on shelves with a maximum height of 1500 mm. The rotation also allows the drum to be placed horizontally at a height of 1650 mm from the ground. RAL 1028 yellow painting. Attention: the drum turner is suitable for handling metal drums or plastic drums with rim (as in the photo). Do not use for different drums.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A specialized conveyor system called a telescopic radial stacker is used in material handling applications to stack bulk materials in radial stockpiles with efficiency. This equipment has an extendable and retractable telescopic boom that expands its reach and facilitates radial or circular material stacking. By utilizing the radial stacking feature the stacker can maximize storage capacity in a constrained footprint by forming stockpiles with a larger diameter.Effective bulk material management and storage is achieved through the widespread use of telescopic radial stackers in the mining construction and aggregate processing industries.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Telescopic Radial Conveyor Belt Radial Stacker is a specialized equipment used in material handling applications to efficiently stack bulk materials in radial patterns. This equipment combines the functionalities of a telescopic conveyor belt and a radial stacker to offer enhanced flexibility and efficiency in material stacking operations. The telescopic feature allows the conveyor belt to extend or retract, enabling it to reach varying distances for stacking materials, while the radial stacking capability enables the creation of organized radial stockpiles of bulk materials. By integrating telescopic and radial functionalities, this equipment optimizes material stacking processes and enhances storage capacity within a limited space footprint. The operational principle of a Telescopic Radial Conveyor Belt Radial Stacker involves extending the telescopic conveyor belt to reach the desired stacking location and efficiently conveying materials to create radial stockpiles.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A specialized conveyor system called a telescopic radial stacker is used in material handling applications to stack bulk materials in radial stockpiles with efficiency. This equipment has an extendable and retractable telescopic boom that expands its reach and facilitates radial or circular material stacking. By utilizing the radial stacking feature the stacker can maximize storage capacity in a constrained footprint by forming stockpiles with a larger diameter.Effective bulk material management and storage is achieved through the widespread use of telescopic radial stackers in the mining construction and aggregate processing industries. To work the telescopic radial stacker extends its boom to the desired stacking area. From there materials are dispersed radially along the booms length. An even distribution of materials is created in a circular stockpile as the materials leave the conveyor belt because the stacker rotates around a central pivot point.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Telescopic Radial Conveyor Belt Radial Stacker is a specialized equipment used in material handling applications to efficiently stack bulk materials in radial patterns. This equipment combines the functionalities of a telescopic conveyor belt and a radial stacker to offer enhanced flexibility and efficiency in material stacking operations. The telescopic feature allows the conveyor belt to extend or retract, enabling it to reach varying distances for stacking materials, while the radial stacking capability enables the creation of organized radial stockpiles of bulk materials. By integrating telescopic and radial functionalities, this equipment optimizes material stacking processes and enhances storage capacity within a limited space footprint. The operational principle of a Telescopic Radial Conveyor Belt Radial Stacker involves extending the telescopic conveyor belt to reach the desired stacking location and efficiently conveying materials to create radial stockpiles.

Request for a quote

VLADIMIR PLANT OF RUBBER TECHNICAL INDUSTRY (VLADRTI LLC)

Russia

Rubber crumb with a fraction of 2-4 mm is one of the important components necessary for the manufacture of artificial turf for sports grounds and running tracks, as well as for covering children's and playgrounds. Terms of use: • Temperature of working materials, base surface and environment from +10°С to +40°С. • The crumb rubber should be dry and should not contain rubber dust, textile cord, etc. • The temperature of the binder should range from +15°С to +25°С • The surface temperature of the base should be at least 3°C above the dew point. Use on on damp bases is prohibited; • The surface should be dust-free, degreased, cleaned of contaminants • Exposure to atmospheric precipitation is undesirable during the day after laying the coating Laying technology: The crumb can be used both at manual laying of coverings, and when using automatic stackers.

Request for a quote

VLADIMIR PLANT OF RUBBER TECHNICAL INDUSTRY (VLADRTI LLC)

Russia

Rubber crumb with a fraction of 1-3 mm is one of the important components necessary for the manufacture of artificial turf for sports grounds and running tracks, as well as for covering children's and playgrounds. Terms of use: • Temperature of working materials, base surface and environment from +10°С to +40°С. • The crumb rubber should be dry and should not contain rubber dust, textile cord, etc. • The temperature of the binder should range from +15°С to +25°С • The surface temperature of the base should be at least 3°C above the dew point. Use on on damp bases is prohibited; • The surface should be dust-free, degreased, cleaned of contaminants • Exposure to atmospheric precipitation is undesirable during the day after laying the coating Laying technology: The crumb can be used both at manual laying of coverings, and when using automatic stackers.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The ultra-light COMPACT storage and retrieval machine opens up flexible options for use in existing warehouses. The consistently lightweight design reduces kinematic loads on the floor panels and conserves energy. Transverse forces in the rack are also minimal. A lower approach dimension of 0 millimeters allows the use of conventional stacker racks. No storage space is lost in the lowest rack level. Depending on the application, the COMPACT machines can be equipped with a variety of load handling attachments. High handling capacities and individual location access are achieved with single- or double-deep telescopic forks from DAMBACH. With the patented rotating and swiveling traverse fork, pallets can be picked up or set down at floor level to meet the needs of manual warehouse operation. The tilting device even makes it possible to transport pallets with closed bottoms.

Request for a quote

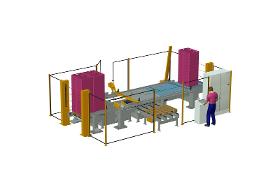

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Economic + maintenance friendly articulated arm robot alternative • Flexible plastic case + carton tray stacking heights • Changeover times for gripper and format parts are eliminated due to automatic format changeovers • Unit performance can be expanded through additional stackers • Use of Euro pallets, Duesseldorfer half pallets + industrial pallets Within limited space situations the fully automatic stacking and palletizing unit is the first choice for flexible handling of all market formats. The slimly designed Stacker is economical + mainteance friendly when it comes to stacking plastic cases, meat crates, nestable carton and trays, mixed pallet commissioning or bakery baskets without pallets . Product and format changeovers are software controlled and require no tools. The Stack Palletizer is ideally suited for palletizing pre-stacked containers and the shuttle system allows for collecting different product stacks and creating mixed product pallet loads.

Results for

Stacker- used - Import exportNumber of results

11 ProductsCountries

Company type